Synthesis method for Ag-In-Zn-S/CQDs heterojunction material

A technology of ag-in-zn-s and synthesis method, which is applied in the field of synthesis of Ag-In-Zn-S/CQDs heterojunction materials, achieves the effects of convenient mass production, excellent photocatalytic activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2A

[0026] Example 2 Characterization and Analysis of Ag-In-Zn-S / CQDs Heterojunction Photocatalyst

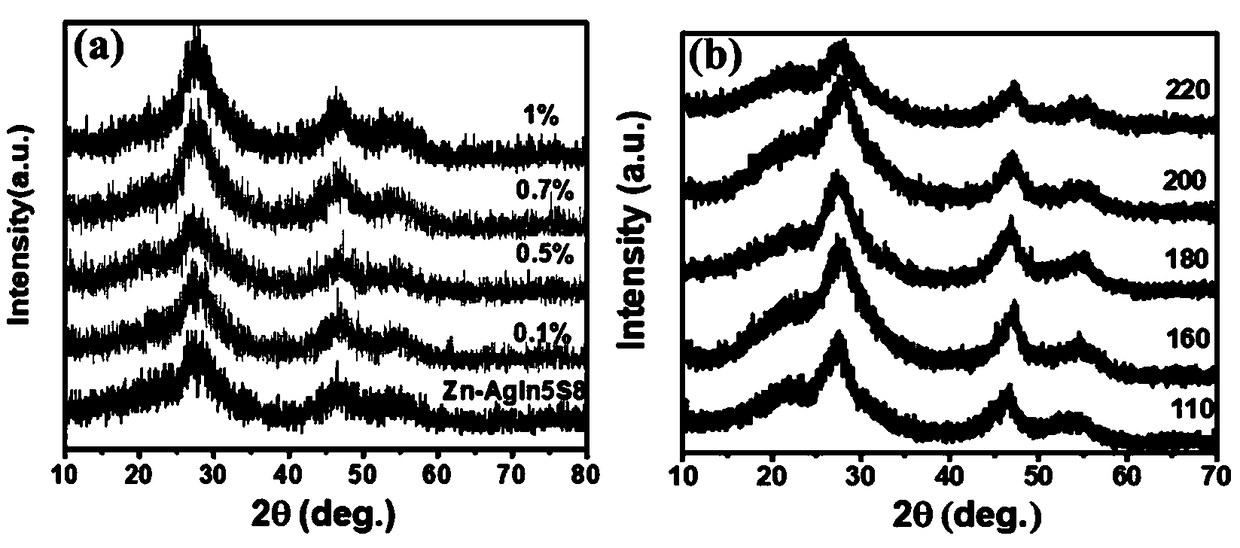

[0027] figure 1 , it can be seen from the figure that although the amount of CQDs changes and the loading is 10wt%, when changing different temperatures, there are mainly peaks of Ag-In-Zn-S nanocrystals and no other miscellaneous peaks, nor The peaks of CQDs appear. The reason for this phenomenon is that the amount of carbon quantum dots added is relatively small, and the peak of carbon quantum dots is covered by the peak of Ag-In-Zn-S quantum dots.

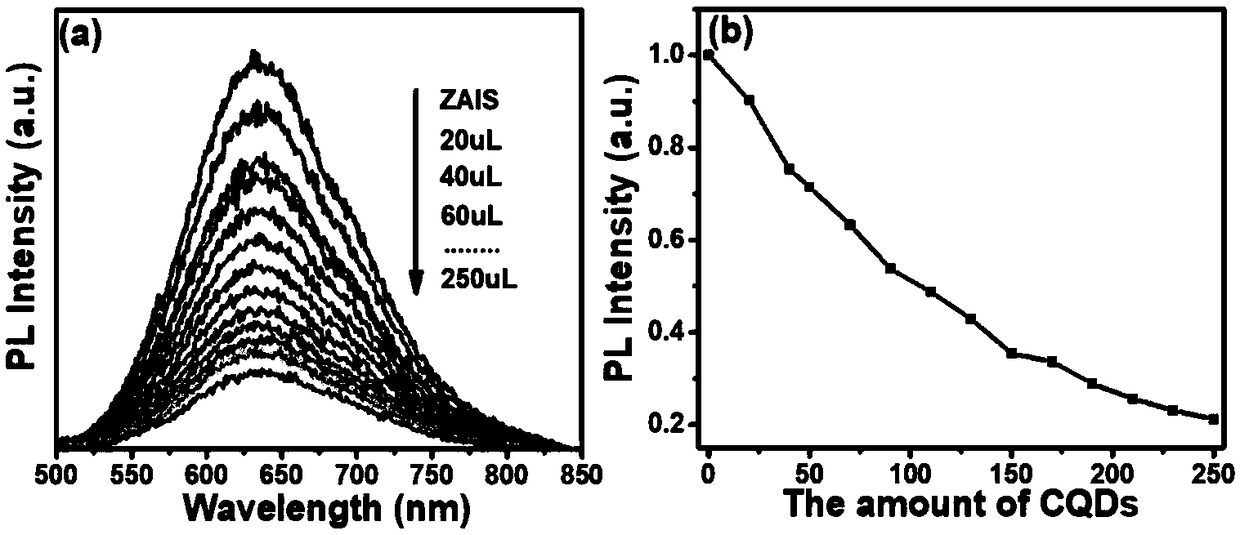

[0028] figure 2 From the figure, we can see that the fluorescence intensity of the pure ZAIS quantum dots drops with the amount of drops, and the fluorescence intensity gradually decreases. In the figure (b), we can accurately see the fluorescence quenching state, which is It is said that electron transfer can occur between ZAIS quantum dots and CQDs. It provides a reference for exploring the appropriate CQDs loading and photoca...

Embodiment 3A

[0033] Example 3 Visible light catalytic hydrogen production experiment of Ag-In-Zn-S / CQDs photocatalyst

[0034] (1) Configure 5M sodium sulfide solution.

[0035] (2) Weigh 20 mg of Ag-In-Zn-S catalyst samples with different CQDs loadings, and place them in 35 mL reaction flasks.

[0036] (3) Then weigh 0.4725g of sodium sulfite and 1ml of 5M sodium sulfide solution into the reaction flask, and ultrasonicate for 5min.

[0037] (4) Afterwards, put it on the nine-channel for illumination, and use a 1mL syringe to extract 1ml of gas every 1h and inject it into the gas chromatograph for detection. After data processing, we can get Figure 6 hydrogen production map. Under the condition of adding sacrificial agent, the hydrogen production rate of heterojunction visible light photocatalytic water splitting loaded with 10wt% CQDs is twice that of pure Ag-In-Zn-S quantum dots. It shows that an appropriate amount of CQDs supported on Ag-In-Zn-S quantum dots can further improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com