Method for synthesizing copper-indium/carbon bimetal nano material through one-step reduction method and application of copper-indium/carbon bimetal nano material

A bimetallic nano-reduction technology, applied in the field of electrochemistry, can solve the problems of copper-indium/carbon bimetallic nanomaterial electrodes that have not yet been discovered, achieve excellent electrochemical activity and stability, easy industrial implementation, and simple operation process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The one-step reduction method synthesizes copper-indium / carbon bimetallic nanomaterial electrodes, including the following steps:

[0031] Step 1: Dissolve 1.5 mmol indium chloride in 20 mL, 0.1 M hydrochloric acid solution to form solution A;

[0032] Step 2: prepare 0.2 M citric acid solution with deionized water, i.e. solution B;

[0033] Step 3: Pour 20mL of solution A into 20mL of solution B under magnetic stirring, then add 212.8 mg of carbon black to form a suspension C, and ultrasonicate for 30 minutes until uniformly dispersed;

[0034] Step 4: Vigorously stir the uniformly dispersed suspension C in an ice bath, slowly drop into the newly prepared 25 mL, 0.6 M sodium borohydride solution to form a suspension D, and then stir at 200 rpm for 2 h;

[0035] Step 5: Centrifuge the suspension D at 10,000 rpm, wash the product with deionized water several times, and dry it under vacuum at 60 °C for 12 h to obtain the catalyst In 1.5 / C.

Embodiment 2

[0037] The one-step reduction method synthesizes copper-indium / carbon bimetallic nanomaterial electrodes, including the following steps:

[0038] Step 1: Dissolve 1.0 mmol copper chloride in 20 mL, 0.1 M hydrochloric acid solution to form solution A;

[0039] Step 2: prepare 0.2 M citric acid solution with deionized water, i.e. solution B;

[0040] Step 3: Pour 20mL of solution A into 20mL of solution B under magnetic stirring, then add 212.8 mg of carbon black to form a suspension C, and ultrasonicate for 30 minutes until uniformly dispersed;

[0041] Step 4: Vigorously stir the uniformly dispersed suspension C in an ice bath, slowly drop into the newly prepared 25 mL, 0.4 M sodium borohydride solution to form a suspension D, and then stir at 200 rpm for 2 hours;

[0042] Step 5: Centrifuge the suspension D at 10,000 rpm, wash the product with deionized water several times, and dry it in vacuum at 60 °C for 12 h to obtain the catalyst Cu 1.0 / C.

Embodiment 3

[0044] The one-step reduction method synthesizes copper-indium / carbon bimetallic nanomaterial electrodes, including the following steps:

[0045] Step 1: Dissolve 0.5 mmol indium chloride and 0.5 mmol copper chloride in 20 mL, 0.1 M hydrochloric acid solution to form solution A;

[0046] Step 2: prepare 0.2 M citric acid solution with deionized water, i.e. solution B;

[0047] Step 3: Pour 20mL of solution A into 20mL of solution B under magnetic stirring, then add 212.8 mg of carbon black to form a suspension C, and ultrasonicate for 30 minutes until uniformly dispersed;

[0048] Step 4: Vigorously stir the uniformly dispersed suspension C in an ice bath, slowly drop into the newly prepared 25 mL, 0.4 M sodium borohydride solution to form a suspension D, and then stir at 200 rpm for 2 hours;

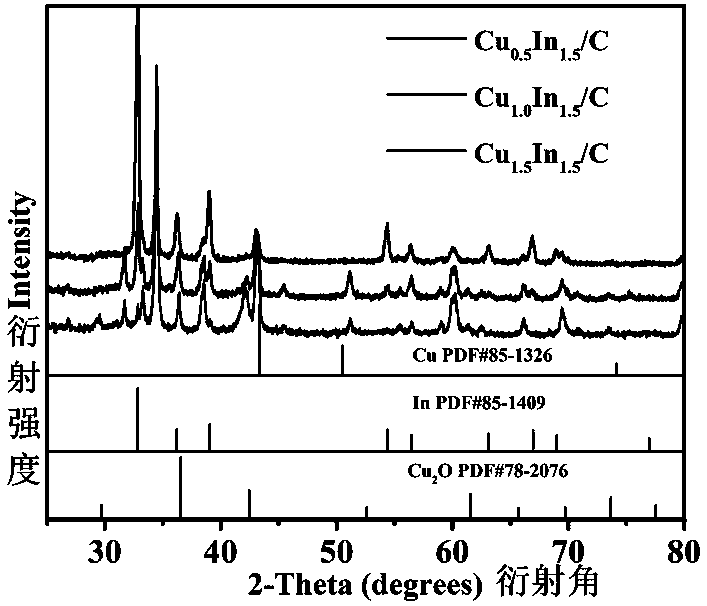

[0049]Step 5: Centrifuge the suspension D at 10,000 rpm, wash the product with deionized water several times, and dry it in vacuum at 60 °C for 12 h to obtain the catalyst Cu 0.5 In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com