Method for preparing indium oxide cubes through microwave-assisted hydrothermal method

A microwave-assisted, indium oxide technology, which is applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problem of long time consumption of precursor solution, achieve low cost, facilitate industrial production, and good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An indium oxide (In 2 o 3 ) The preparation method of cube is to carry out according to the following steps:

[0028] A. Weigh the molar ratio of 1:0.5 indium nitrate (In(NO 3 ) 3 4.5 H 2 O) and urea, dissolved in 100 mL of deionized water, was configured into a uniform colorless and transparent solution after magnetic stirring for 30 min;

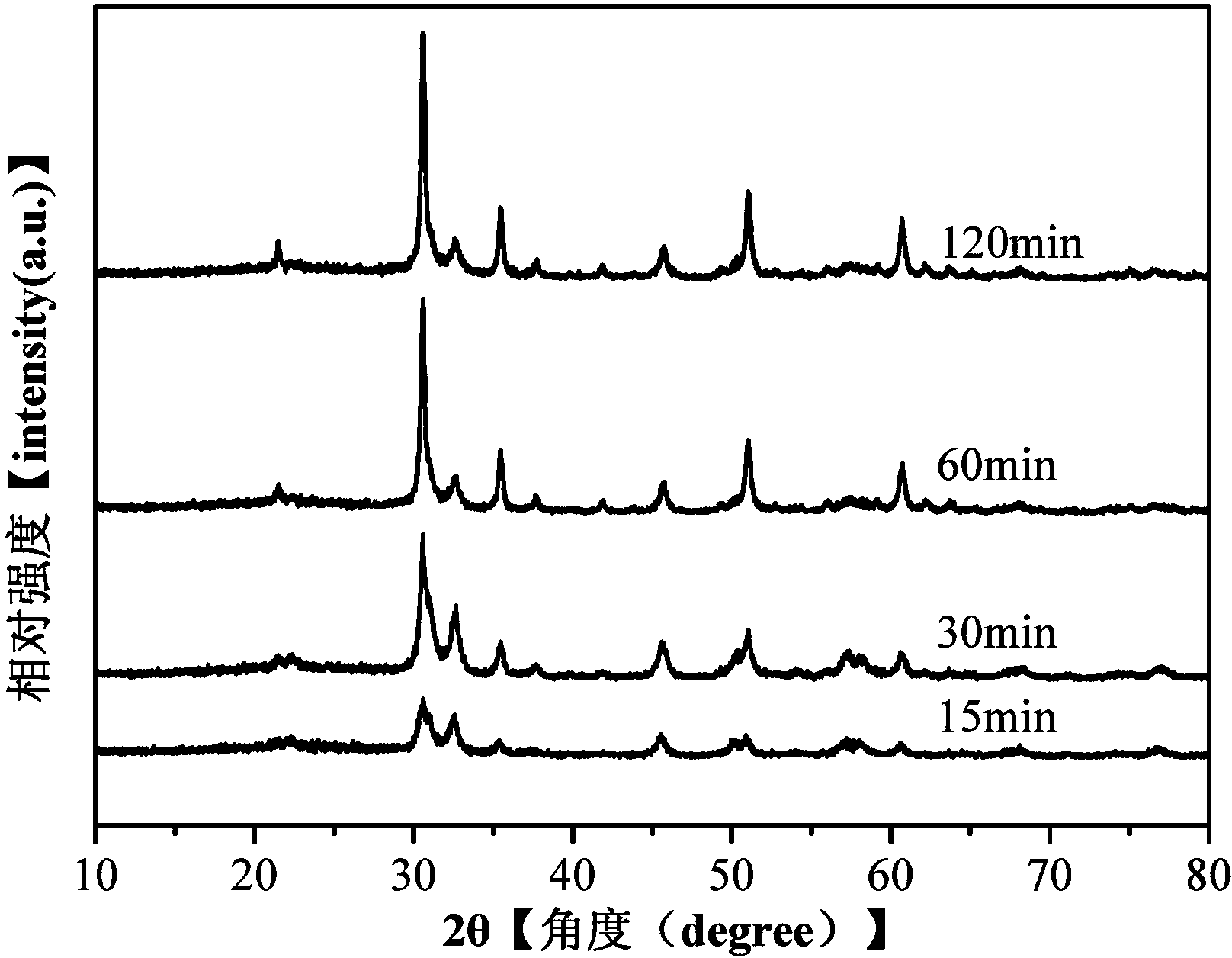

[0029]B. Transfer the solution obtained in step A to a quartz container with a capacity of 250mL, place it in a microwave reactor, heat up to 80°C, and heat it for 15min with a power of 600W, then cool naturally and collect the microwave product;

[0030] C, centrifuging the microwave product obtained in step B, washing with deionized water and absolute ethanol three times respectively;

[0031] D, the centrifuged product obtained in step C was dried in the air at 60°C for 6 h to obtain indium hydroxide (In(OH) 3 )Precursor;

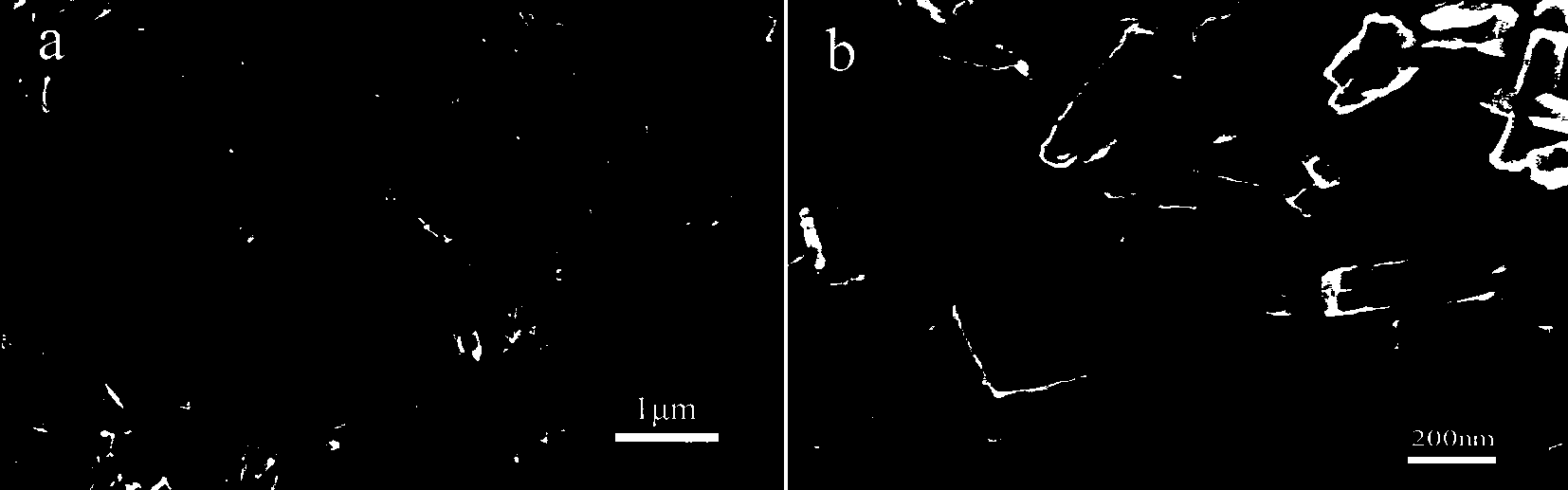

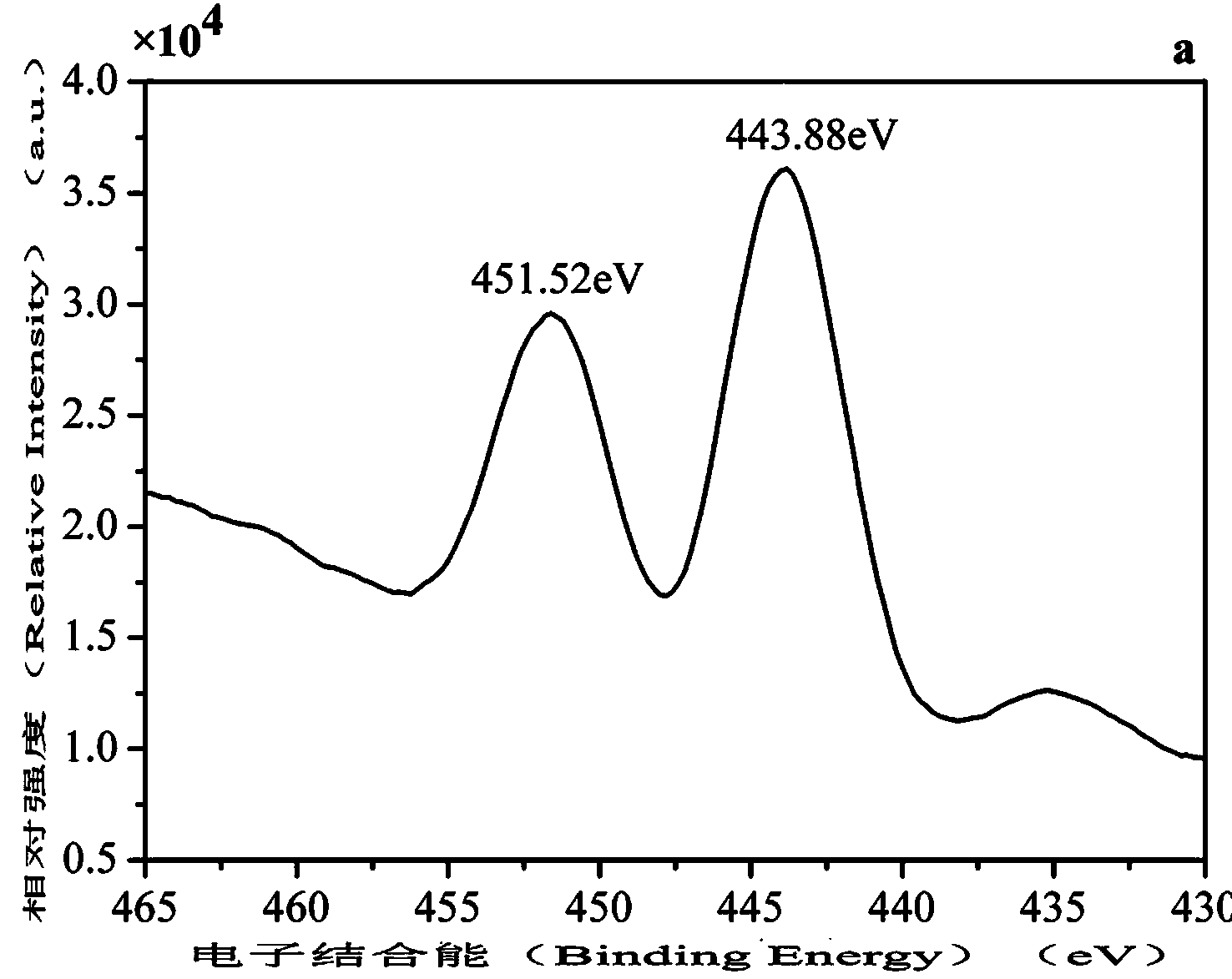

[0032] E, the indium hydroxide (In(OH) obtained in step D 3 ) precursors were calcined in a muffle ...

Embodiment 2

[0038] An indium oxide (In 2 o 3 ) The preparation method of cube is to carry out according to the following steps:

[0039] A. Weigh the molar ratio of 1:7 indium nitrate (In(NO 3 ) 3 4.5 H 2 O) and urea, dissolved in 100 mL of deionized water, was configured into a uniform colorless and transparent solution after magnetic stirring for 30 min;

[0040] B. Transfer the solution obtained in step A to a quartz container with a capacity of 250mL, place it in a microwave reactor, heat up to 100°C, heat it for 120min with a power of 1000W, cool it naturally, and collect the microwave product;

[0041] C, centrifuging the microwave product obtained in step B, washing with deionized water and absolute ethanol three times respectively;

[0042] D, the centrifuged product obtained in step C was dried in the air at 60°C for 6 h to obtain indium hydroxide (In(OH) 3 )Precursor;

[0043] E, the indium hydroxide (In(OH) obtained in step D 3 ) precursors were calcined in a muffle fur...

Embodiment 3

[0045] An indium oxide (In 2 o 3 ) The preparation method of cube is to carry out according to the following steps:

[0046] A. Weigh the molar ratio of 1:0.9 indium nitrate (In(NO 3 ) 3 4.5 H 2 O) and urea, dissolved in 100 mL of deionized water, was configured into a uniform colorless and transparent solution after magnetic stirring for 30 min;

[0047] B. Transfer the solution obtained in step A to a quartz container with a capacity of 250mL, place it in a microwave reactor, heat up to 90°C, heat it at 800W for 90min, cool it naturally, and collect the microwave product;

[0048] C, centrifuging the microwave product obtained in step B, washing with deionized water and absolute ethanol three times respectively;

[0049] D, the centrifuged product obtained in step C was dried in the air at 60°C for 6 h to obtain indium hydroxide (In(OH) 3 )Precursor;

[0050] E, the indium hydroxide (In(OH) obtained in step D 3 ) precursors were calcined in a muffle furnace at 400 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com