Method for preparing BiOCl with adjustable thickness at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of BiOCl monomer

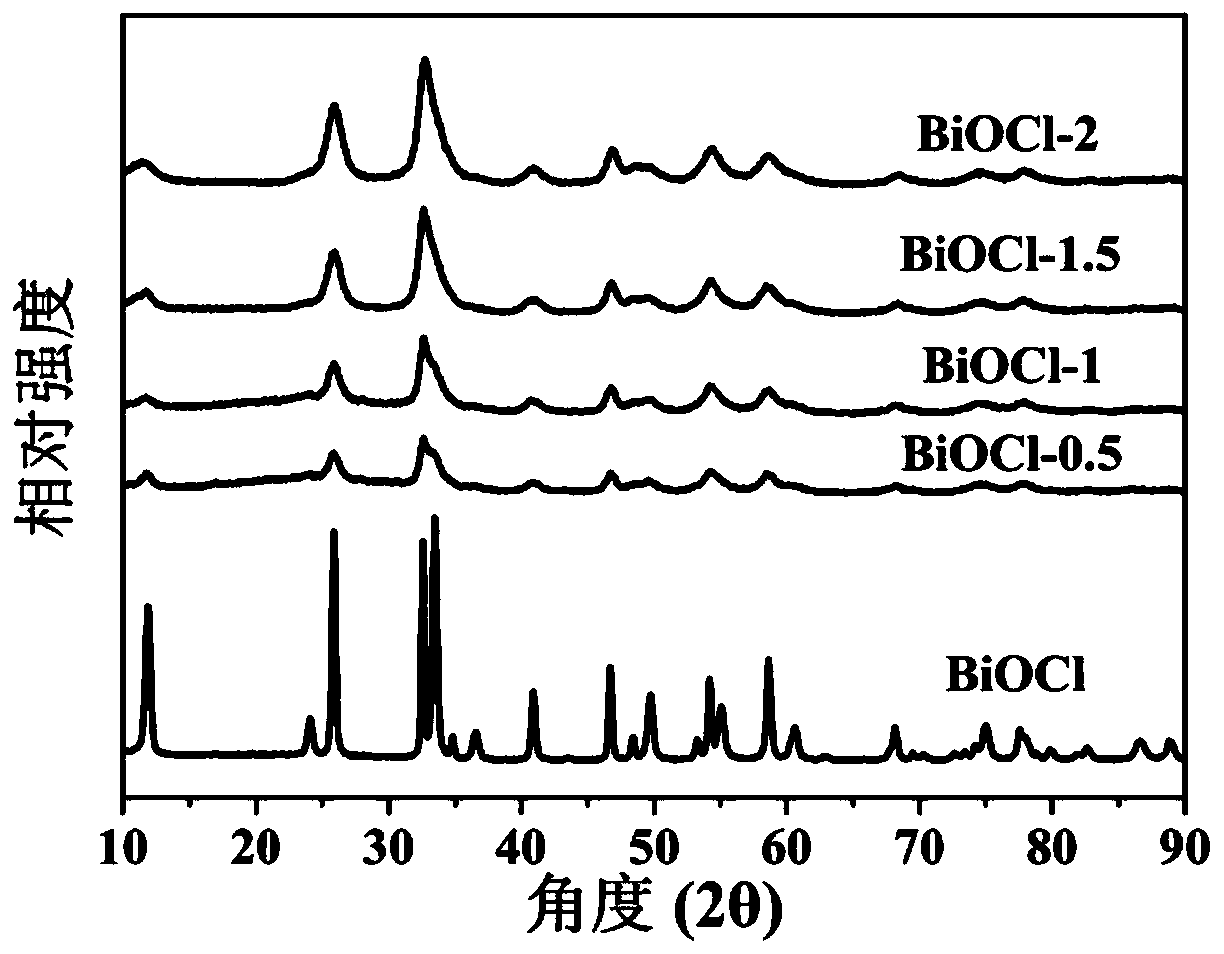

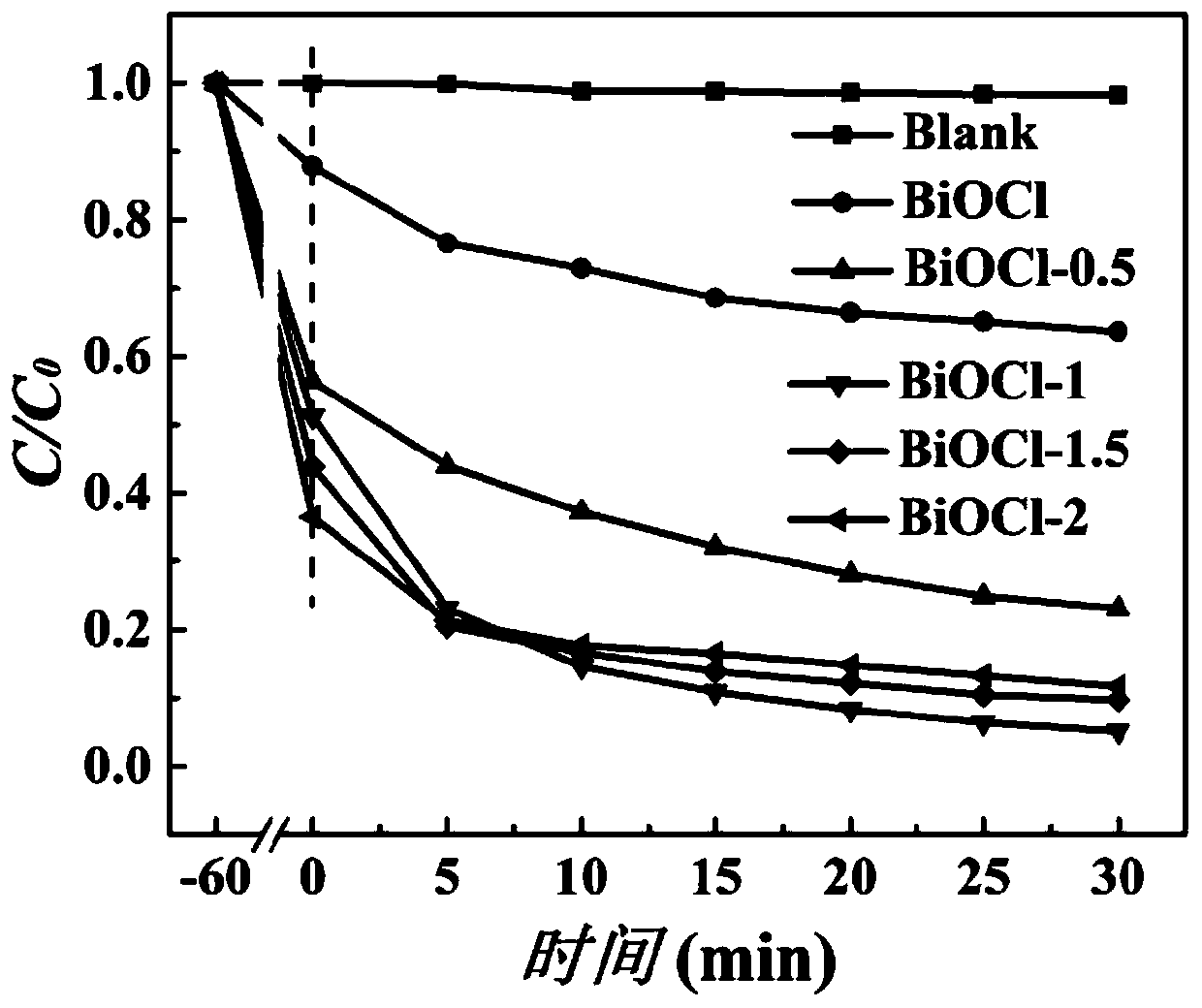

[0031] First, 0.97 g of Bi(NO 3 ) 3 ·5H 2 O was added to 60 mL of aqueous solution and stirred for another 20 minutes. Then 10 mL of 1 mol / L hydrochloric acid solution was added. After stirring for 30 minutes, the precipitate was collected, washed repeatedly with ultrapure water and ethanol, and dried at 60°C to obtain BiOCl nanosheets, which were used for subsequent blank experiments.

[0032] 2) Preparation of BiCOl photocatalyst with adjustable thickness

[0033] Disperse 0.5, 1, 1.5, 2g (molar ratio 1:50-300) of mannitol respectively in 60mL of ultrapure water, stir well to dissolve, then add 0.97g of Bi(NO 3 ) 3 ·5H 2 O was added therein respectively, and after stirring for 20 minutes, 10 mL of 1 mol / L hydrochloric acid solution was added respectively. After stirring for 30 minutes, the obtained precipitate was centrifuged, washed repeatedly with ultrapure water and ethanol, and dried at 80°C to obtain BiOCl- 0.5, BiOCl-1, ...

Embodiment 2

[0038] 1) Preparation of BiOCl monomer

[0039] First, 0.97 g of Bi(NO 3 ) 3 ·5H 2 O was added to 60 mL of aqueous solution and stirred for another 20 minutes. Then 10 mL of 1 mol / L sodium chloride solution will be added. After stirring for 30 minutes, the precipitate was collected, washed repeatedly with ultrapure water and ethanol, and dried at 60°C to obtain BiOCl nanosheets, which were used for subsequent blank experiments.

[0040] 2) Preparation of BiCOl photocatalyst with adjustable thickness

[0041] Disperse 0.5, 1, 1.5, and 2 g of mannitol in 60 mL of ultrapure water, and stir to dissolve them, then add 0.97 g of Bi(NO 3 ) 3 ·5H 2 O was added therein respectively, after stirring for 20 minutes, 10 mL of 1 mol / L sodium chloride solution was added respectively, after stirring for 30 minutes, the precipitate obtained was centrifuged, washed repeatedly with ultrapure water and ethanol, and dried at 80°C to obtain BiOCl-0.5, BiOCl-1, BiOCl-1.5, BiOCl-2 nanosheets....

Embodiment 3

[0043] 1) Preparation of BiOCl monomer

[0044] First, 0.97 g of Bi(NO 3 ) 3 ·5H 2 O was added to 60 mL of aqueous solution and stirred for another 20 minutes. Then 10 mL of 1 mol / L potassium chloride solution will be added. After stirring for 30 minutes, the precipitate was collected, washed repeatedly with ultrapure water and ethanol, and dried at 60°C to obtain BiOCl nanosheets, which were used for subsequent blank experiments.

[0045] 2) Preparation of BiCOl photocatalyst with adjustable thickness

[0046] Disperse 0.5, 1, 1.5, and 2 g of mannitol in 60 mL of ultrapure water, and stir to dissolve them, then add 0.97 g of Bi(NO 3 ) 3 ·5H 2 O was added therein respectively, after stirring for 20 minutes, 10 mL of 1 mol / L potassium chloride solution was added respectively, after stirring for 30 minutes, the obtained precipitate was centrifuged, washed repeatedly with ultrapure water and ethanol, and dried at 80°C to obtain BiOCl-0.5, BiOCl-1, BiOCl-1.5, BiOCl-2 nanos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com