Method for preparing polysilicate iron flocculating agent from iron-containing heave metal sludge, and recycling treatment method of heavy metal sludge

A technology of heavy metal sludge and polyferric silicate, applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, sludge treatment, etc. The effect is not good, the processing process is complicated, etc., to achieve the effect of convenient resource utilization, solving resource problems, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

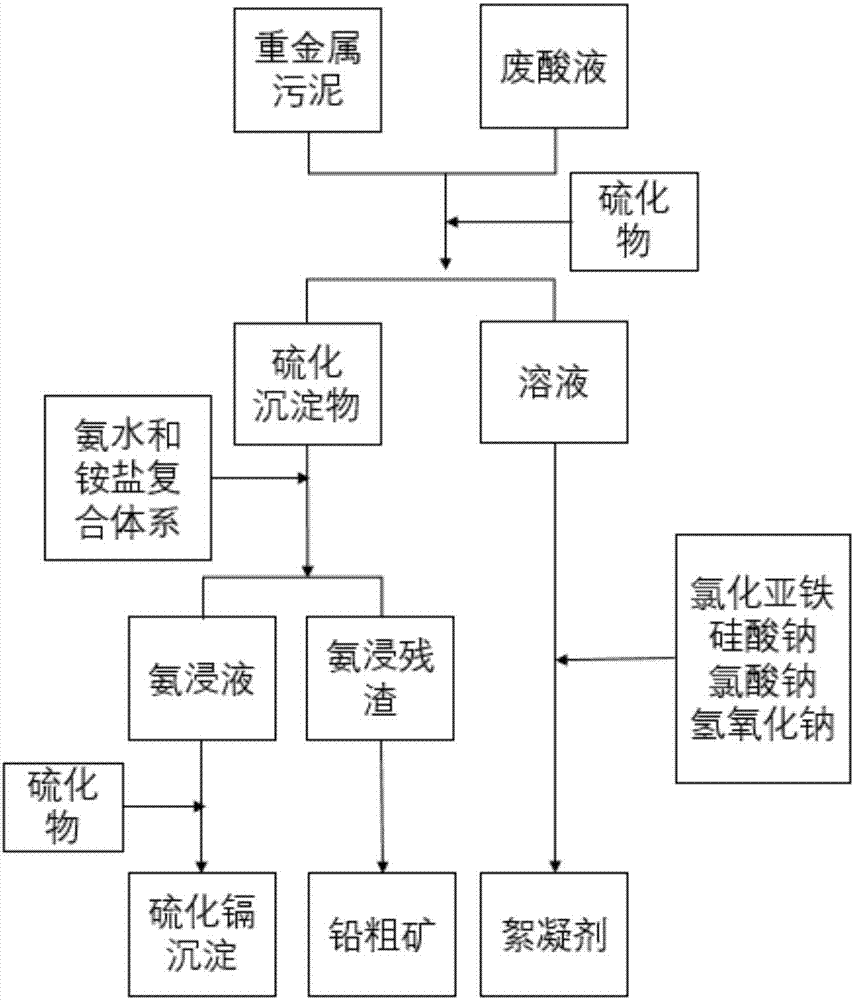

Method used

Image

Examples

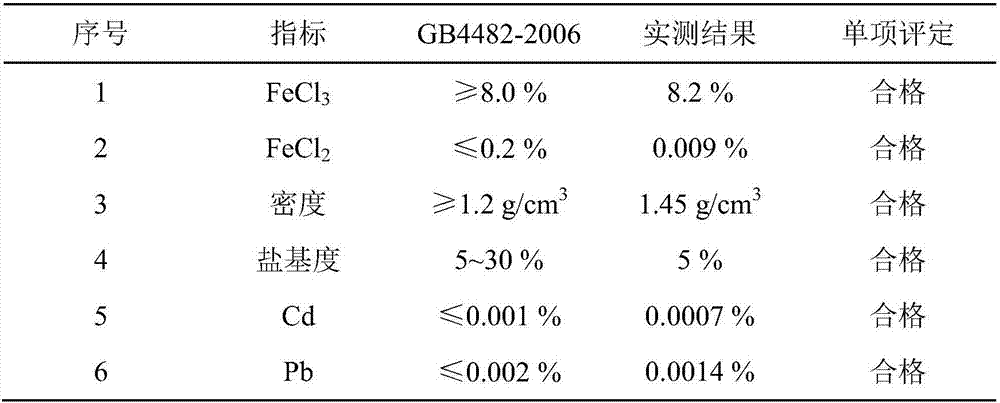

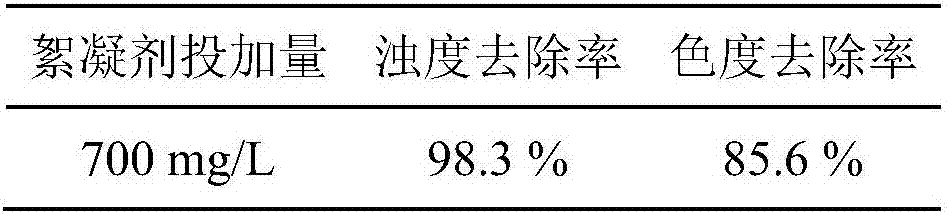

Embodiment 1

[0041] A preparation method of polysilicate ferric silicate flocculant taking iron-containing heavy metal sludge as raw material comprises the following steps:

[0042] (1) According to the mass ratio of industrial waste acid and heavy metal sludge (4-6):1, add industrial waste acid to the heavy metal sludge, after dissolving the heavy metal sludge, adjust the pH to 6.0-6.5, in the solution Add sulfide to the sludge to make heavy metal cadmium and lead ions in the sludge become complex precipitates, and the solution after solid-liquid separation is used as a flocculant preparation solution. The industrial waste acid is one of waste hydrochloric acid, waste sulfuric acid, and waste nitric acid. One or two or more kinds of sulfides are N,N-dimethylcarbamodithioformate, N,N-diethylcarbamodithiocarbamate or their derivatives. The ratio of the amount of substance of lead and cadmium to the amount of total substance of lead and cadmium is (4~5):1 for calculation;

[0043] (2) Add a...

Embodiment 2

[0066] The operation steps of this embodiment 2 are basically the same as that of embodiment 1, the difference is that:

[0067] In this embodiment 2, in order to process 1t of heavy metal sludge (each heavy metal content is total iron 460kg, lead 6kg, cadmium 2kg), use 4t waste sulfuric acid to dissolve in step (1), add 14kg N,N-dimethylamino Sodium dithioformate; Supplement ferrous chloride tetrahydrate solid 321kg in the step (2), make the total iron content in the solution account for the mass fraction of the solution after treatment to be 9%; Add 100kg sodium silicate nonahydrate in the step (3) With 145kg sodium chlorate, the feeding time is 60min, and the stirring speed is 350r / min; Potassium hydroxide is added in the step (4), and the basicity is adjusted to 15%; the rotating speed of the agitator is 350r / min in the step (5), The stirring reaction time is 90min, the standing aging time is 18h, and the density of the aging liquid obtained is 1.40g / cm 3 .

[0068] The ...

Embodiment 3

[0082] The operating steps of this embodiment 3 are basically the same as those of embodiment 1, the difference being:

[0083] In this embodiment 3, in order to process 1t of heavy metal sludge (each heavy metal content is total iron 600kg, lead 6kg, cadmium 1.8kg), use 5t waste nitric acid to dissolve in step (1), add 17kg N,N-diethyl Sodium carbamate; Supplement ferrous chloride tetrahydrate solid 360kg in the step (2), make the total iron content in the solution account for the mass fraction of the solution after treatment to be 9.5%; Add 90kg silicic acid nonahydrate in the step (3) Sodium and 172kg sodium chlorate, feed time is 60min, and stirring speed is 450r / min; Add sodium hydroxide and potassium hydroxide in step (4), regulate salinity to 30%; The rotating speed of stirrer in step (5) is 450r / min, the stirring reaction time is 120min, the standing aging time is 24h, and the density of the aging solution obtained is 1.55g / cm 3 .

[0084] The performance index of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com