Method for preparing yellow pigment by using commonly used color development for replacing rare-earth element praseodymium and vanadium color development

A yellow pigment and rare earth element technology, applied in the field of ceramic coloring and pigments, can solve the problems of weakening competitiveness, rising prices, affecting the normal production of praseodymium vanadium yellow materials, etc., to achieve the effect of expanding the scope of application and sustainable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

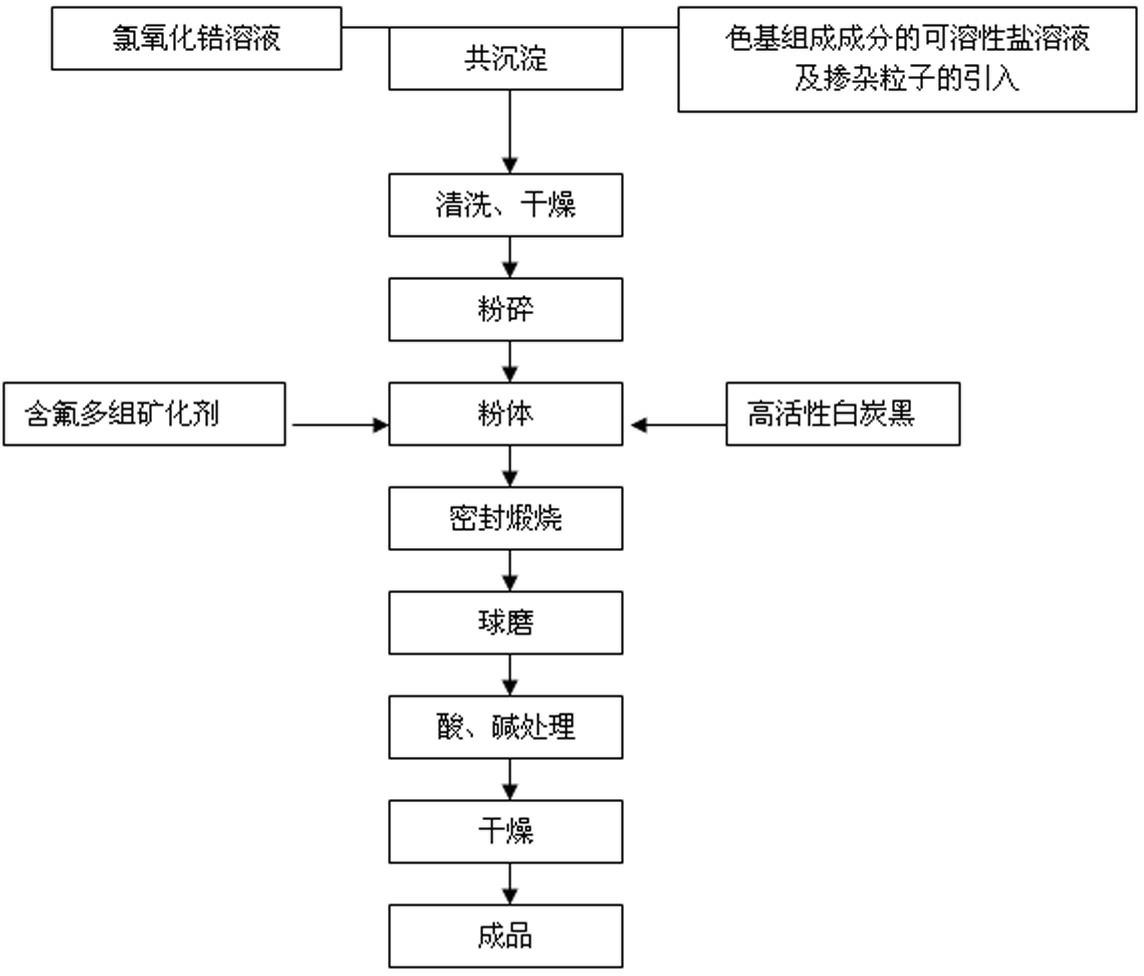

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific experimental examples.

[0028] One of the schemes of the present invention is to replace zirconium praseodymium yellow:

[0029] Zirconium oxychloride, cadmium sulfate, sodium sulfide, highly active white carbon black, fluorine-containing multigroup mineralizers, caustic soda, and zinc chloride are selected as raw materials. The first step adopts the liquid-phase synthesis method, using zinc chloride to dope zinc ions, and the mass percentages of the main control components zirconium oxychloride, cadmium sulfate, sodium sulfide, zinc chloride, and caustic soda are: 67-68%, 11.5% ~12%, 7~8%, 0.5~2%, 11~12%, control the concentration of each material added: 180~200g / ml, 30~34 g / ml, 20~22 g / ml, 2~ 6 g / ml, 30-36 g / ml; zinc chloride is introduced by dissolving in cadmium sulfate, and the pH value is controlled at 5.5-8.5. The second step uses solid-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com