Method for improving stability of hydrogen sulfide-sensitive tin dioxide gas sensor material

A gas-sensing material, tin dioxide technology, applied in the field of gas-sensing sensors, can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] commercial SnO 2 Nanomaterials are sensitive materials. Prepare 200mL of sodium thiosulfate aqueous solution with a concentration of 0.1mol / L, add appropriate amount of SnCl 4 ·5H 2 O, weighed SnO 2 The powder is placed in the above solution, sodium thiosulfate: SnCl 4 ·5H 2 O: SnO 2 The molar ratio is 3:1:30, stir for 3 hours, add 20 mL of tartaric acid; place in a reaction kettle, react at 120 °C for 3.5 hours; wait until the temperature drops to room temperature, centrifuge and dry the sample;

[0019] Put the above sample precursor and urea into a high-energy ball mill, the mass ratio of precursor to urea is 3:1, ball mill at 350 r / min in Ar atmosphere for 8 hours, and then put it in a muffle furnace for 5 hours at 450 °C. , to obtain the surface porous SnSO4-modified SnO 2 Nano powder.

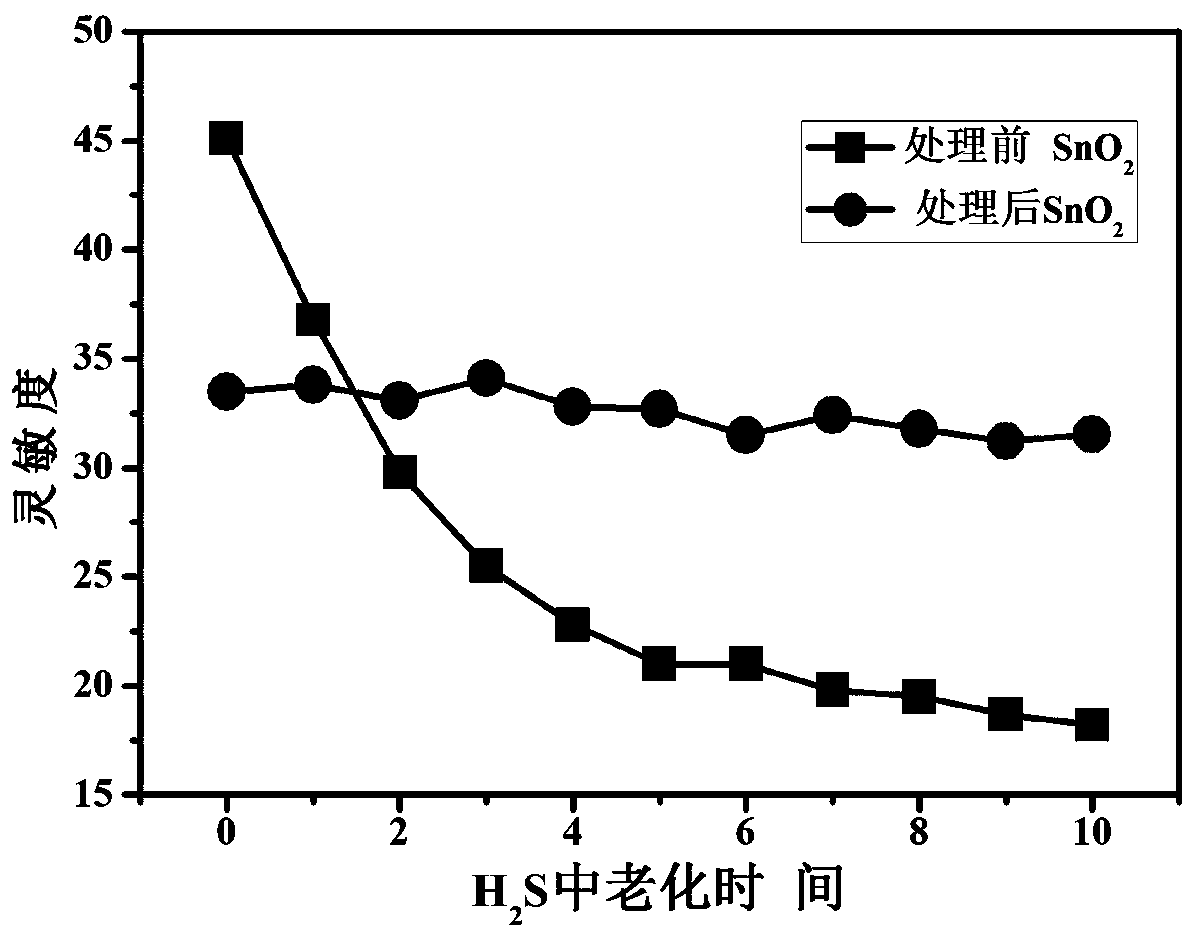

[0020] figure 1 is a commercial SnO 2 With the sample treated in this example, the H of 10 ppm 2 Sensitivity comparison chart of S gas, the working temperature is 230 ℃,...

Embodiment 2

[0022] commercial SnO 2 Nanomaterials are sensitive materials. Mix 200mL of sodium thiosulfate aqueous solution with a concentration of 0.3mol / L, add appropriate amount of SnCl 4 ·5H 2 O, weighed SnO 2 The powder is placed in the above solution, sodium thiosulfate: SnCl 4 ·5H 2 O: SnO 2 The molar ratio was 2:1:30, stirred for 3 hours, and 30 mL of malic acid was added; placed in a reaction kettle, reacted at 120 °C for 5 hours; when the temperature dropped to room temperature, the sample was centrifuged and dried.

[0023] Put the above sample precursor and urea into a high-energy ball mill, the mass ratio of the precursor to urea is 5:1, ball mill at 300 r / min for 10 hours in an Ar atmosphere, and then put it into a muffle furnace for calcination at 350 °C for 6 hours , to obtain the surface porous SnSO4-modified SnO 2 Nano powder.

[0024] This embodiment and embodiment 1 adopt the same commercial SnO 2 , the treated sample reacts to 10 ppm H 2 S gas sensitivity in...

Embodiment 3

[0026] SnO synthesized by hydrothermal method 2 Nanomaterials are sensitive materials. Prepare 200mL of sodium sulfite aqueous solution with a concentration of 0.2mol / L, add appropriate amount of SnCl 4 ·5H 2 O, weighed SnO 2 The powder is placed in the above solution, sodium sulfite: SnCl 4 ·5H 2 O: SnO 2 The molar ratio was 2:1:40, stirred for 3 hours, added 60 mL of citric acid; placed in a reaction kettle, reacted for 3 hours at 180 ° C; when the temperature dropped to room temperature, the sample was centrifuged and dried;

[0027] Put the above sample precursor and urea into a high-energy ball mill with a mass ratio of precursor to urea of 5:1, ball mill for 2 hours at 500 r / min in an Ar atmosphere, and then put it into a muffle furnace for calcination at 350 °C for 6 hours , to obtain the surface porous SnSO4-modified SnO 2 Nano powder.

[0028] SnO directly synthesized by hydrothermal method 2 powder to 10 ppm H 2 S gas sensitivity at 73.2, at H 2 After be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com