A filter press

A filter press and filter technology, applied in the field of filter presses, can solve the problems of affecting the dehydration effect, increase power consumption, reduce vacuum degree, etc., and achieve the effects of reducing shrinkage, increasing service life, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

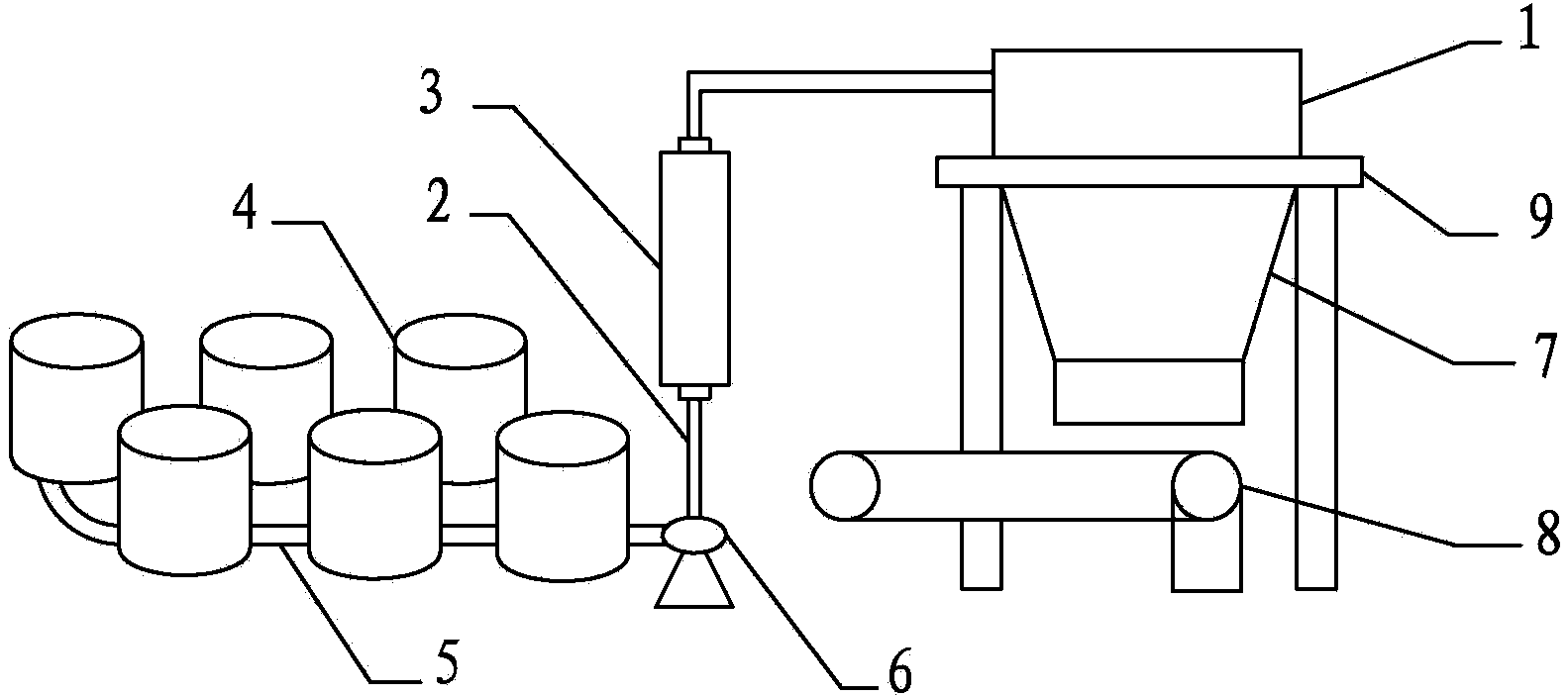

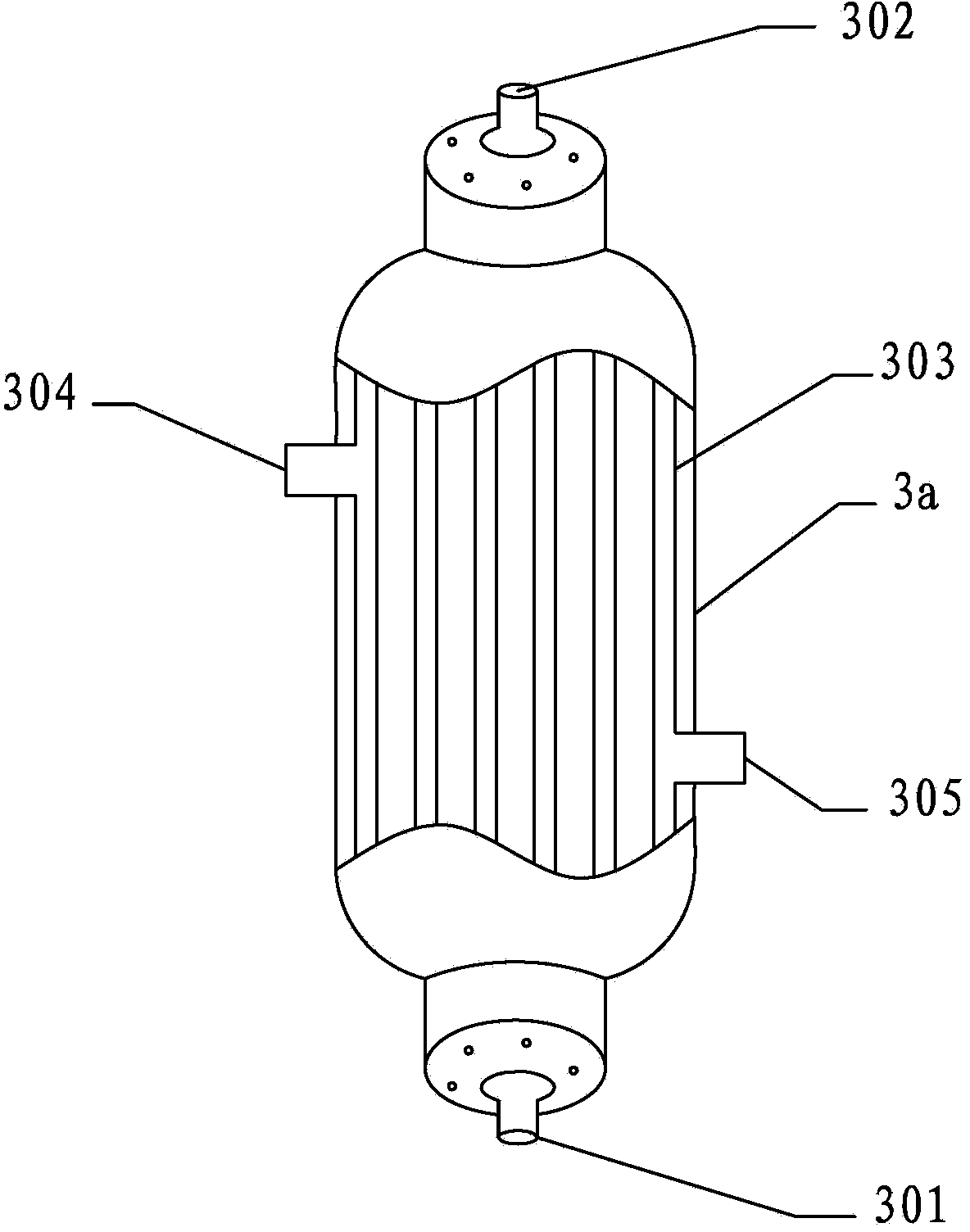

[0017] Such as figure 1 with figure 2 As shown, the present invention includes a filter press body 1 and a feed pipe 2 for conveying the finished slurry into the filter body 1. The feed pipe 2 is provided with a heat exchanger 3 that can reduce the temperature of the finished slurry. The heat exchanger 3 includes a heat exchanger body 3a with a cavity inside, the lower end of the heat exchanger body 3a is provided with a finished slurry inlet 301 communicating with the cavity, and the upper end of the heat exchanger body 3a is provided with a cavity The cavity is connected to the finished slurry outlet 302, and a number of interconnected pipes 303 are arranged in the cavity, and the pipes 303 are provided with a cooling water inlet 304 for inflowing cold water and a hot water outlet 305 for outflowing hot water. A centrifugal pump 6 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com