Diaphragm for lithium ion battery, production method thereof, and battery core

A technology for a lithium ion battery and a production method, applied in the field of lithium ion batteries, can solve the problems of easy piercing of the separator, easy generation of dendrites, etc., and achieve the effects of reducing volume expansion, increasing absorption, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

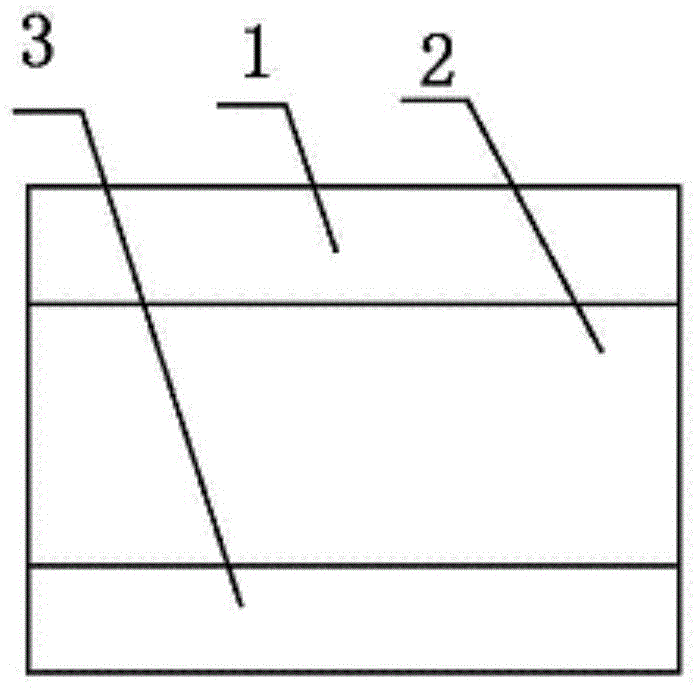

[0049] (1) Pretreatment of diaphragm:

[0050] At 80°C, the volume ratio of the prepared chromic acid oxidation solution is: K 2 Cr 2 o 7 :H 2 SO 4 :H 2 O=1:20:2, soak the polyethylene (PE) base film in the chromic acid oxidizing solution for 30 minutes, and corrode the base film by the acid oxidizing solution to corrode the surface of the base film so that the base film becomes a porous structure . Then rinse off the oxidizing solution with deionized water several times, and dry it for later use.

[0051] (2) Coating of aluminum nitride: Coating an aluminum nitride (AlN) nano film on the surface of the pretreated base film corresponding to the negative electrode, wherein the thickness of the AlN film is at the micron level, the specific method As follows: Put the aluminum nitride (AlN) ceramic powder into the vacuum radio frequency sputtering equipment, the side not coated with PTFE is used as the substrate, adjust the voltage and current of the equipment and the radio...

Embodiment 2

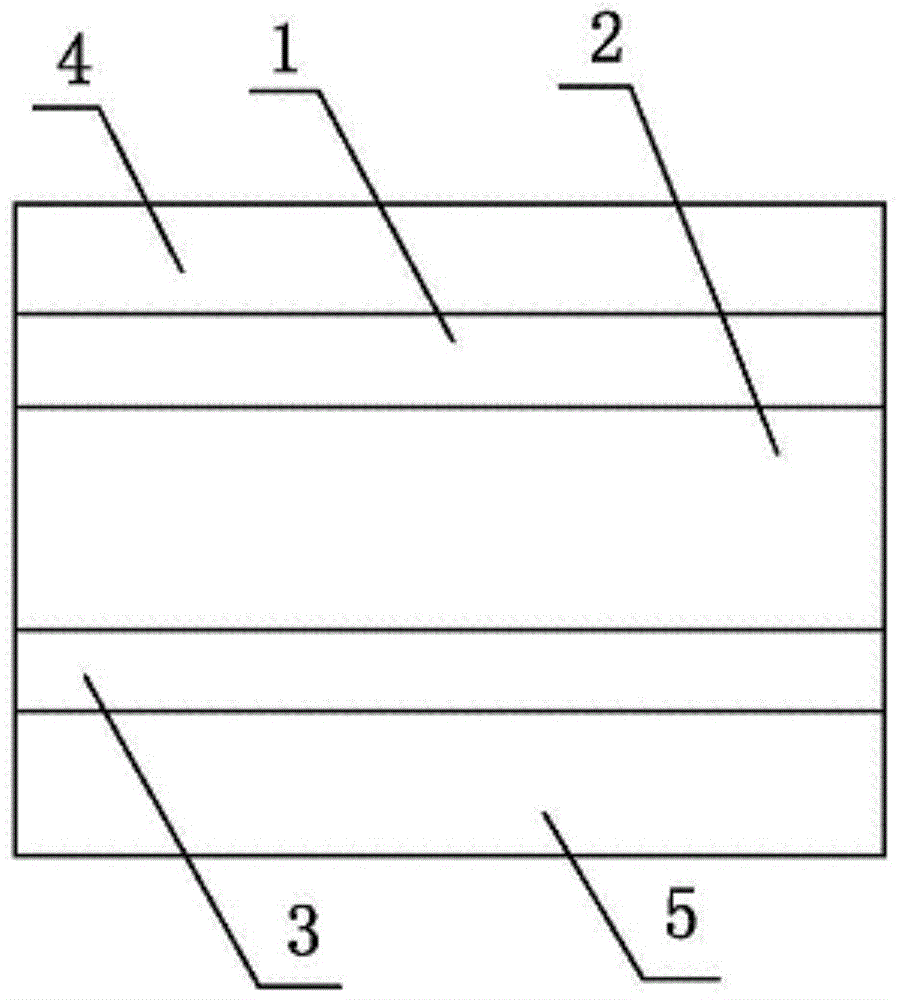

[0053] (1) Pretreatment of diaphragm:

[0054] At 80°C, the volume ratio of the prepared chromic acid oxidation solution is: K 2 Cr 2 o 7 :H 2 SO 4 :H 2 O=1:20:2, soak the 20μm-thick composite diaphragm produced by Celgard (the composition is PP / PE / PP) in the above chromic acid oxidation solution for 30min, and corrode the base film by the acidic oxidation solution to make the base film The surface part is corroded, so that the base membrane becomes porous. Then rinse off the oxidizing solution with deionized water several times, and dry it for later use.

[0055] (2) Coating of PTFE: Add PTFE to absolute ethanol, stir and dissolve at 70°C to obtain a gel solution with a mass fraction of 20%, and apply this solution on the pretreated basement membrane by sol-gel method On the surface corresponding to the positive electrode, the thickness is controlled at about 5 μm. After an hour of absolute ethanol volatilization in the air, it is then immersed in a certain amount of a...

Embodiment 3

[0058] (1) Pretreatment of diaphragm:

[0059] At 80°C, the volume ratio of the prepared chromic acid oxidation solution is: K 2 Cr 2 o 7 :H 2 SO 4 :H 2 O=1:20:2, soak the polyethylene (PE) base film in the above oxidizing solution for 30 minutes, corrode the base film surface part by the acidic oxidizing solution, so that the base film becomes a porous structure, and then Rinse off the oxidizing solution several times with deionized water, and dry it for later use.

[0060] (2) Coating of PVDF: Add PVDF to absolute ethanol, stir and dissolve at 70°C to obtain a gel solution with a mass fraction of 20%, and apply the solution to the pretreated basement membrane by sol-gel method On the surface corresponding to the positive electrode, the thickness is controlled at about 5 μm. After an hour of absolute ethanol volatilization in the air, it is then immersed in a certain amount of absolute ethanol to control the phase inversion of the coating solution. In a drying room at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com