Preparation and application of organic-inorganic composite solid-state electrolyte

A solid electrolyte and inorganic composite technology, applied in solid electrolyte, non-aqueous electrolyte, circuits, etc., can solve the problems of difficult room temperature batteries and low conductivity, and achieve the goal of improving ion conductivity, improving thermal stability, and quantifiable production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

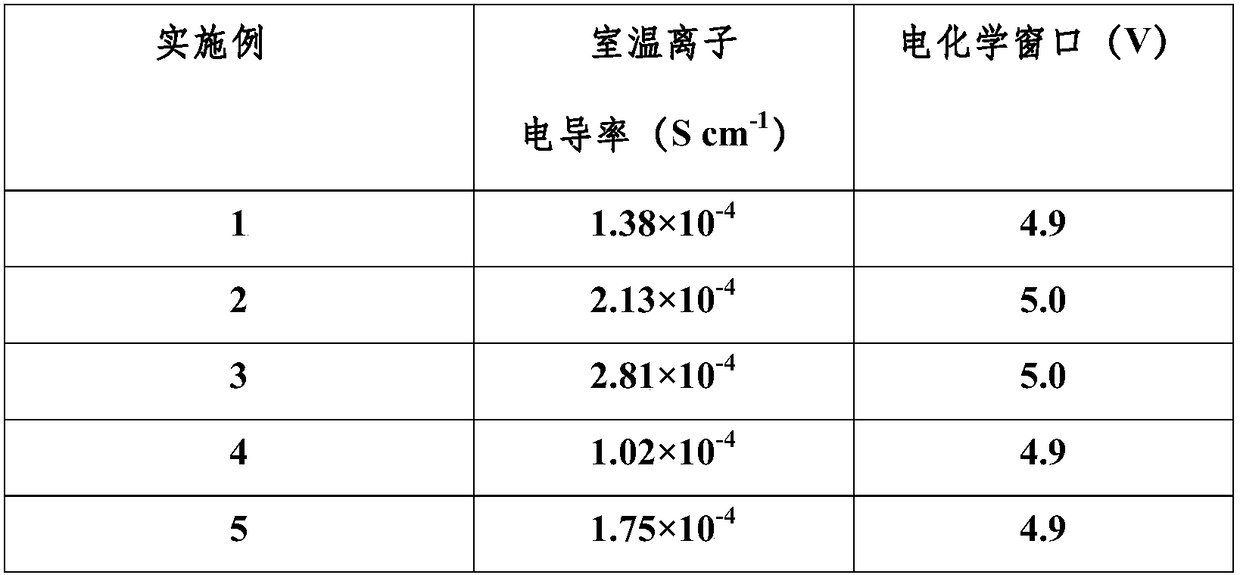

Embodiment 1

[0030] Mix and stir 2.8g HDI trimer, 0.5PEG (Mw=1000), 2.8g nano-alumina, 4ml acetonitrile and tetraethylene glycol dimethyl ether (TEGDME) (V:V=1:1); add 1g lithium hexafluorophosphate ( LiPF 6 ) were mixed evenly to prepare a transparent and clear electrolyte; 0.1g of dibutyltin dilaurate was added dropwise and stirred evenly; the evenly stirred composite polymer electrolyte was scraped onto a polytetrafluoroethylene mold, and heated to 60°C in a glove box , Cured for 12 hours to form a film.

Embodiment 2

[0032] 2.2g HDI trimer, 0.5PEG (Mw=1500), 2g Li 10 GeP 2 S 12 , 4ml tetraethylene glycol dimethyl ether (TEGDME) and 1-methyl-2 pyrrolidone (V:V=1:1) are evenly mixed and stirred; add 0.8g LiN(C 2 f 5 SO 2 ) 2 Mix evenly to prepare a transparent and clear electrolyte; dropwise add 0.12g of dibutyltin dilaurate and stir evenly; scrape the evenly stirred composite polymer electrolyte onto a polytetrafluoroethylene mold, heat it to 60°C in a glove box, and cure 12 hours film formation.

Embodiment 3

[0034] 2.5g HDI, 4g EG, 1g Li 10 GeP 2 S 12 Mix and stir with 2ml tetraethylene glycol dimethyl ether; add 2g LiBOB and mix evenly to prepare a transparent and clear electrolyte; dropwise add 0.06g bis(acetylacetonate) dibutyltin and stir evenly; scrape the evenly stirred composite polymer electrolyte Put it on a polytetrafluoroethylene mold, heat it to 60°C in a glove box, and cure it for 12 hours to form a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com