Preparation method of lithium iron phosphate/carbon nanotube composite material

A technology of carbon nanotubes and lithium iron phosphate, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of low diffusion coefficient of lithium ions, inability to prevent particle aggregation, uneven size distribution, etc. Problems, to achieve simple process, improve electrochemical performance, increase diffusion coefficient and tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Mix deionized water and ethylene glycol (V 水 :V 乙二醇=1:1) to make a mixed solvent, and weigh the raw material according to the molar ratio of 1:1:3:3:6:6: 0.01mol FeSO 4 ·7H 2 O, 0.01mol H 3 PO 4 , 0.03mol LiOH·H 2 O, 0.03mol citric acid, 0.06mol polyvinylpyrrolidone K-30 (polyvinylpyrrolidone, PVP) or polyethylene glycol-400 low molecular weight (polyethylene glycol, PEG-400) and 0.06mol single-walled carbon nanotubes (CNT);

[0036] 2) Take 60ml of the mixed solvent prepared in step 1), first add LiOH·H 2 O and H 3 PO 4 Mix and stir with the mixed solvent in a beaker to prepare a solution with a total molar concentration of 0.67mol / L, and then place the beaker in an ultrasonic cleaner to ultrasonically disperse and dissolve the solution;

[0037] 3) Add FeSO to the solution obtained in step 2) while stirring 4 ·7H 2 O and citric acid are then ultrasonically dispersed and dissolved to obtain a mixed solution with a total molar concentration of 1.33mol / L;

...

Embodiment 2

[0044] Embodiment 2: deionized water and ethylene glycol (V 水 :V 乙二醇 =1:1) to prepare a mixed solvent, and weigh the raw material according to the molar ratio of 1:1:3:5 / 3:10 / 3:10 / 3: 0.01mol FeSO 4 ·7H 2 O, 0.01mol H 3 PO 4 , 0.03mol LiOH·H 2 O, 0.0167mol citric acid, 0.033mol polyvinylpyrrolidone K-30 (polyvinylpyrrolidone, PVP) or polyethylene glycol-400 low molecular weight (polyethylene glycol, PEG-400) and 0.033mol single-wall carbon nanotube (CNT); step The concentration of the lithium source and phosphate source in 2) is 0.5 mol / L, the concentration of the solution after adding the ferrous source and reducing agent in step 3) is 1.5 mol / L, and the amount of sucrose in step 7) is 1% of the precursor The mass percentage is 37%.

[0045] Other steps of material synthesis and preparation, electrode fabrication, battery assembly, characterization techniques, and test conditions are consistent with those in Example 1.

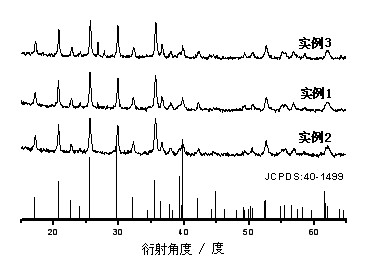

[0046] XRD analysis showed that LiFePO 4 It is a...

Embodiment 3

[0047] Embodiment 3: deionized water and ethylene glycol (V 水 :V 乙二醇 =1:1) to prepare a mixed solvent, and weigh the raw material according to the molar ratio of 1:1:3:1:2:2: 0.01mol FeSO 4 ·7H 2 O, 0.01mol H 3 PO 4 , 0.03mol LiOH·H 2 O, 0.01mol citric acid, 0.02mol polyvinylpyrrolidone K-30 (polyvinylpyrrolidone, PVP) or polyethylene glycol-400 low molecular weight (polyethylene glycol, PEG-400) and 0.02mol single-wall carbon nanotube (CNT); step The concentration of the lithium source and the phosphate source in 2) is 1.5 mol / L, the concentration of the solution after adding the ferrous source and the reducing agent in step 3) is 1 mol / L, and the amount of sucrose added in step 7) is the weight of the precursor The percentage is 40%.

[0048] Other steps of material synthesis and preparation, electrode fabrication, battery assembly, characterization techniques, and test conditions are consistent with those in Example 1.

[0049] XRD analysis showed that LiFePO 4 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com