Silicon composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

a secondary cell and electrode material technology, applied in the field of silicon composite powder, can solve the problems of poor cycle performance, low initial efficiency, low initial efficiency, etc., and achieve excellent cycle performance, alleviate a substantial volume change, and high initial efficiency inherent in silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

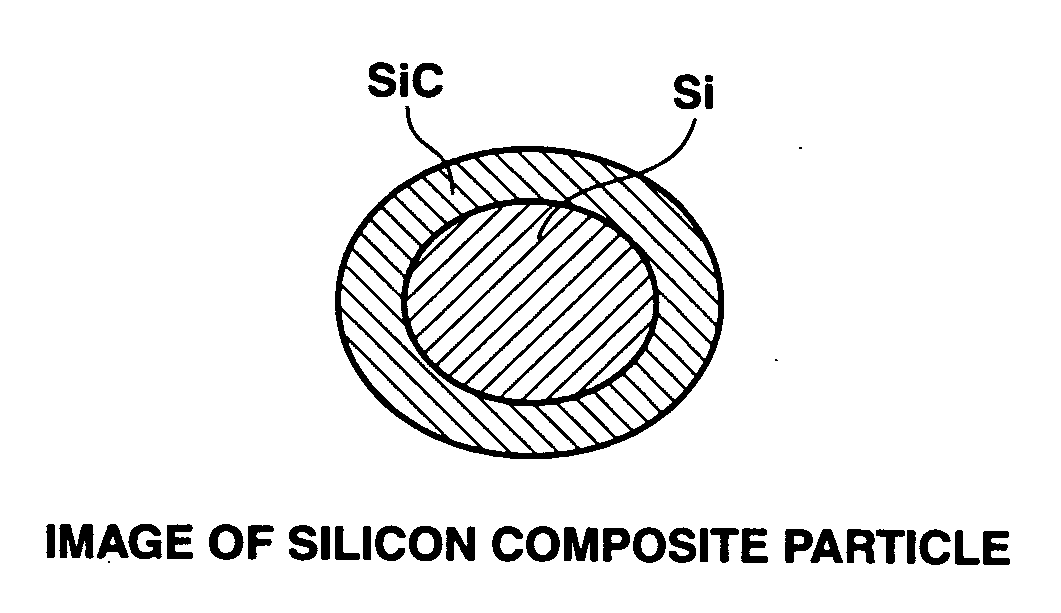

[0047] To illustrate the structure of the silicon composite of the invention, a silicon composite was prepared using a milled powder of industrial metallic silicon.

[0048] A metallic silicon mass of industrial grade was crushed on a crusher, and milled on a ball mill and then a bead mill using hexane as a dispersing medium until fine particles having a predetermined average particle size (about 4 μm) were obtained. A vertical reactor was charged with the silicon fine powder, and thermal CVD was conducted in a stream of a methane-argon mixture at 1,150° C. for an average residence time of about 4 hours. The black mass thus obtained was heated in air at 800° C. for one hour for removing free carbon from the surface. After the oxidizing treatment, the mass was disintegrated on an automated mortar into a fine powder having an average particle size of about 4 μm.

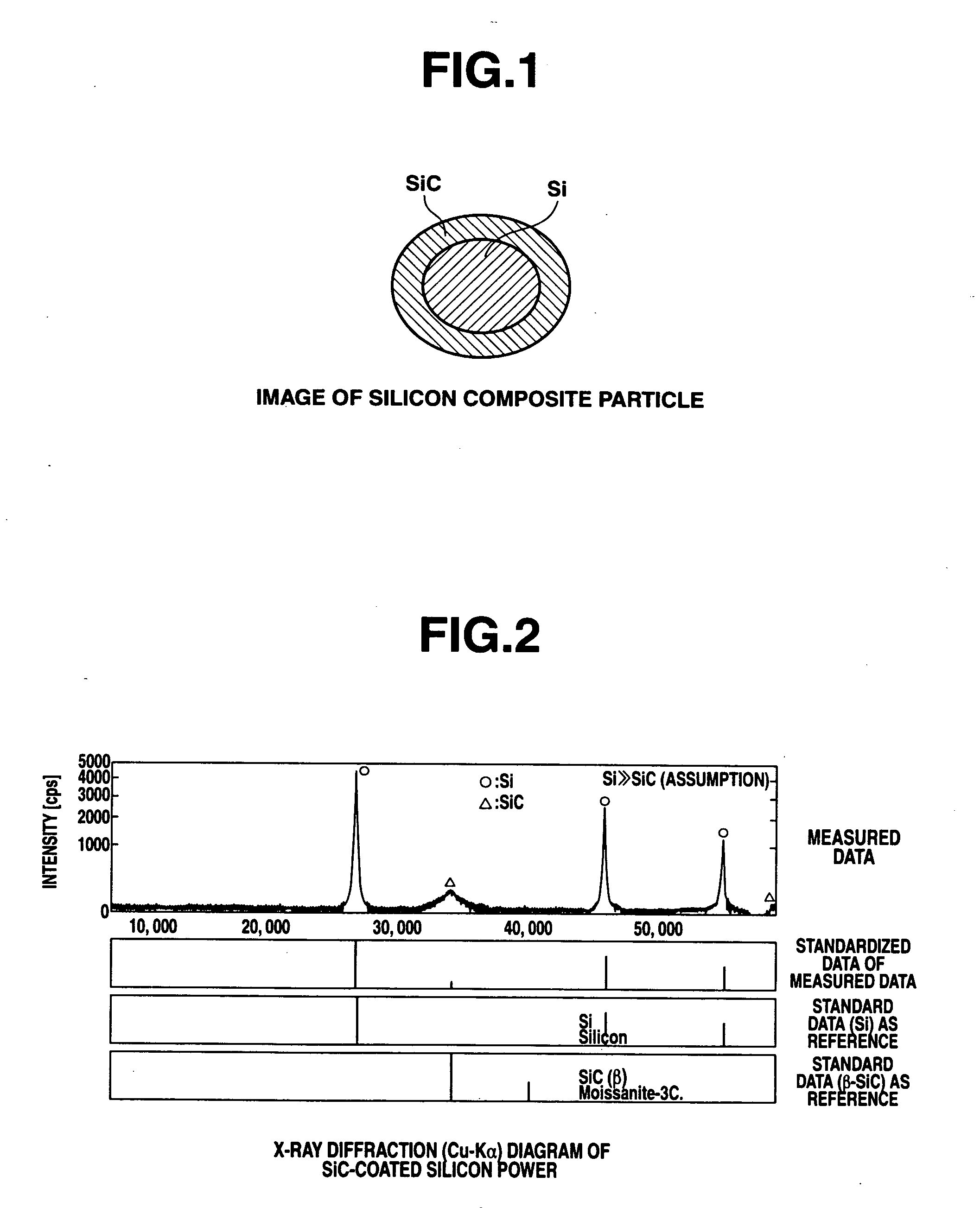

[0049] The silicon composite powder was analyzed by x-ray diffractometry (Cu—Kα). FIG. 2 illustrates an x-ray diffraction patt...

example 2

[0053] A metallic silicon mass of industrial grade (low Al silicon available from SIMCOA Operations Pty. Ltd., Australia, Al 0.4%, Fe 0.21%, etc.) was crushed on a jaw crusher and atomized on a jet mill, obtaining fine silicon particles having an average particle size of about 4 μm. The silicon fine powder was fed to a rotary kiln reactor, and thermal CVD was conducted in a stream of a methane-argon mixture at 1,200° C. for an average residence time of about 2 hours. The black mass thus obtained was disintegrated on an automated mortar. The powder was fed to the rotary kiln reactor again, and thermal CVD was conducted in a stream of a methane-argon mixture at 1,200° C. for an average residence time of about 2 hours. The black mass thus obtained was similarly disintegrated on the automated mortar again. There was obtained a black powder having a total carbon content of 47% and a free carbon content of 36%. The black powder was then placed in an alumina bowl, and heated in air at 800°...

example 3

[0060] The metallic silicon powder with an average particle size of about 4 μm obtained through the pulverization in Example 2 was milled on a bead mill using hexane as a dispersing medium to a predetermined particle size (the target average particle size below 1 μm). A milled silicon powder having an average particle size of about 0.8 μm was obtained. The resulting slurry was passed through a filter for removing hexane, leaving a cake-like mass containing hexane, which was placed in an alumina bowl. The bowl was set in a lateral reactor, and thermal CVD was conducted in a stream of a methane-argon mixture at 1,150° C. for about 2 hours. The black mass thus obtained was disintegrated on an automated mortar. The powder was placed in the alumina bowl and the reactor again, and thermal CVD was conducted under the same conditions. The black mass thus obtained was similarly disintegrated on the automated mortar again. There was obtained a black powder having a total carbon content of 59%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com