Method for preparing lithium titanate/titanium nitride composite material

A composite material, titanium nitride technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of increasing material modification process and increasing production cost, so as to reduce high-temperature burning time, reduce growth, and improve large-scale Effect of current charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh Li according to the ratio of Li:Ti molar ratio of 0.8:1 2 CO 3 and anatase TiO 2 , then by urea and TiO 2Add urea in a molar ratio of 0.4 to 1, use absolute ethanol as a solvent, and ball mill in a planetary ball mill at a speed of 300 rpm for 3 hours. The resulting mixture is dried at room temperature and ground, and placed in a tube furnace In 8mmHg vacuum, the temperature was raised to 800°C at a rate of 10°C / min, kept for 1 hour and then cooled to room temperature. gain 4 Ti 5 o 12 / TiN composite electrode material.

[0028] Material performance characterization:

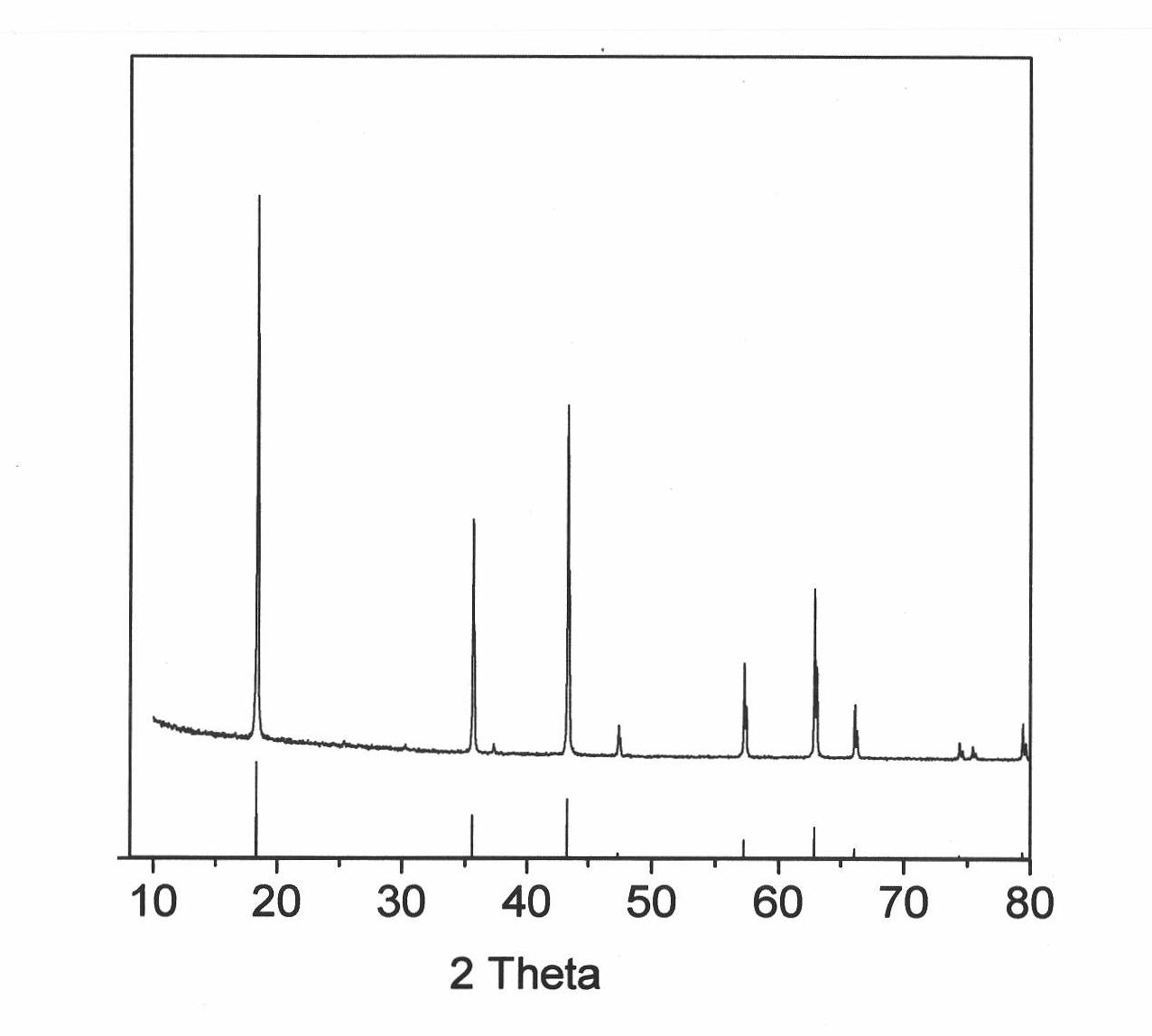

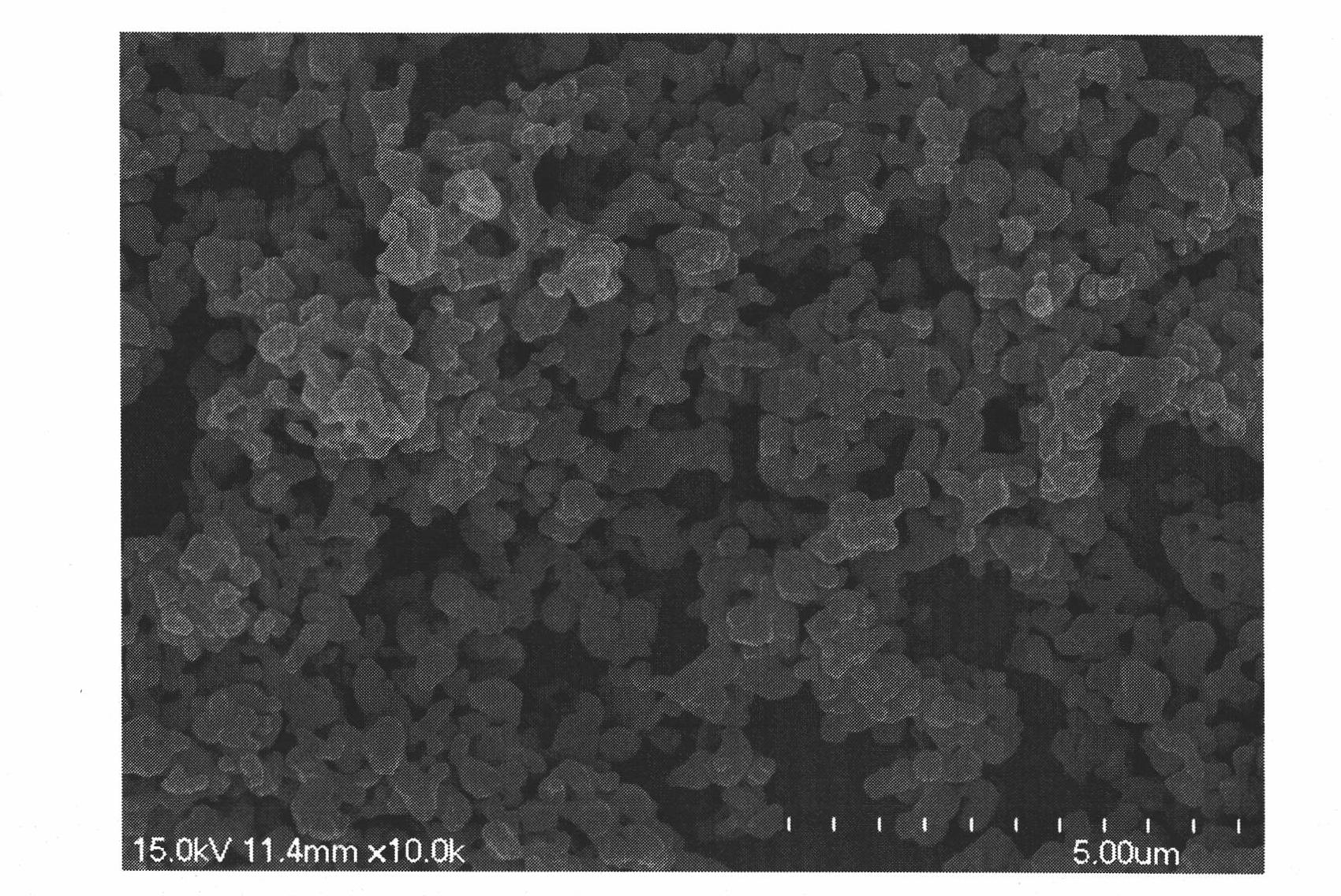

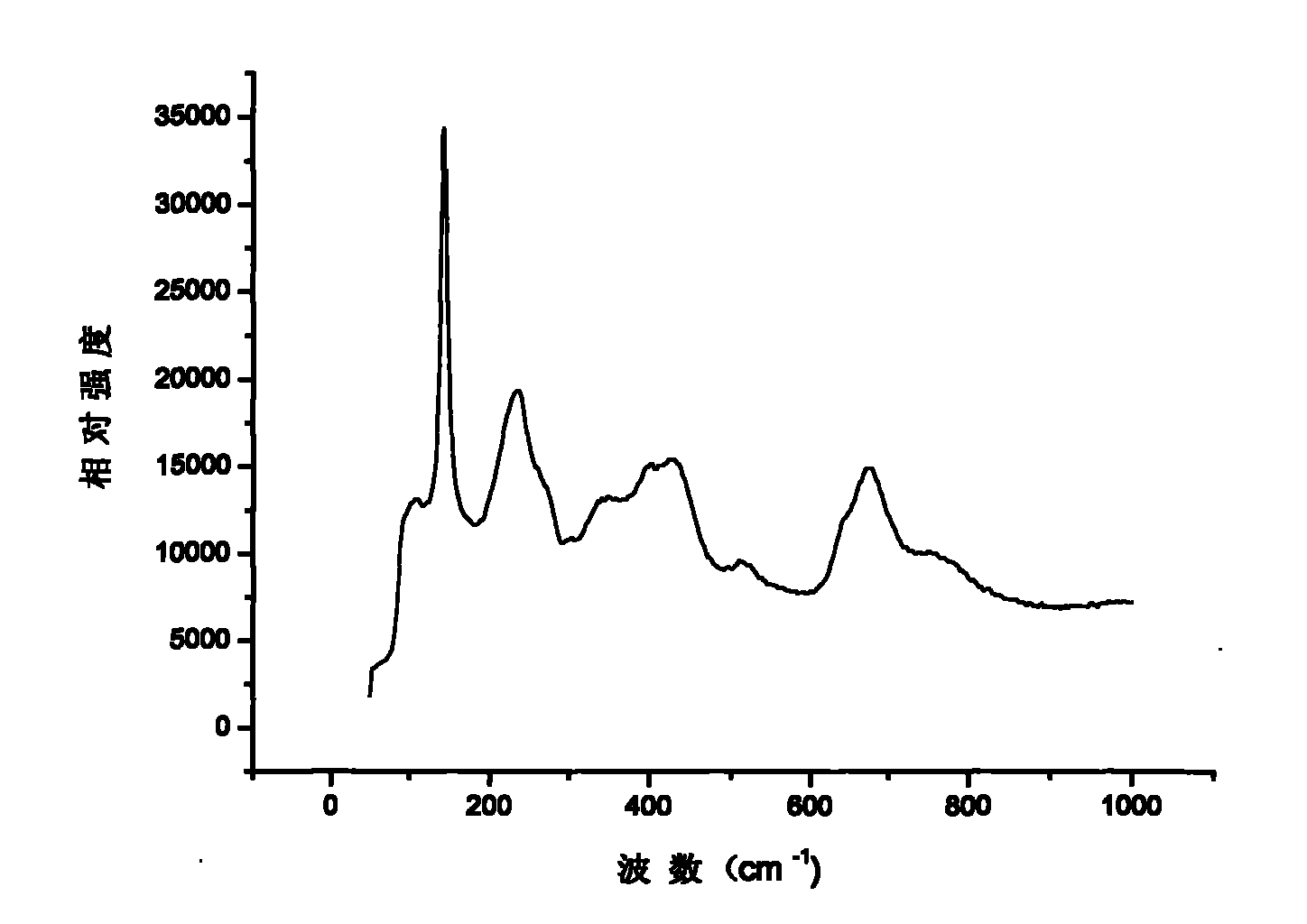

[0029] The crystal structure of the material was analyzed by XRD diffractometer figure 1 , it can be seen from the figure that the crystal structure of the composite electrode material is spinel Li 4 Ti 5 o 12 ; The particle size of the material was analyzed by scanning electron microscopy, and figure 2 , it can be seen from the figure that the composite electrode material is a submicro...

Embodiment 2

[0034] Weigh Li according to the ratio of Li:Ti molar ratio of 0.8:1 2 CO 3 and anatase TiO 2 , then by urea and TiO 2 The molar ratio of 0.2 to 1 was added to urea, and acetone was used as a solvent, and ball milled in a planetary ball mill at a speed of 300 rpm for 3 hours, and the resulting mixture was dried at room temperature and ground, and placed in a tube furnace. The temperature was raised to 750°C at a rate of 5°C / min under 8mmHg vacuum, held for 1 hour and then cooled to room temperature. gain 4 Ti 5 o 12 / TiN composite electrode material.

[0035] The electrochemical test was the same as in Example 1. The Li prepared by embodiment two method and proportioning 4 Ti 5 o 12 The battery made of / TiN composite material has a discharge capacity of 165.5mAh / g at 0.1C, a discharge capacity of 160.2mAh / g at 0.2C, and a discharge capacity of 140.4mAh / g at 0.5C.

Embodiment 3

[0037] Weigh Li according to the ratio of Li:Ti molar ratio of 0.8:1 2 CO 3 and anatase TiO 2 , then by urea and TiO 2 The molar ratio of 0.3 to 1 was added to urea, and acetone was used as a solvent, and ball milled in a planetary ball mill at a speed of 300 rpm for 3 hours, and the resulting mixture was dried at room temperature and ground, and placed in a tube furnace. The temperature was raised to 850°C at a rate of 5°C / min under argon flow, held for 1 hour and then cooled to room temperature. gain 4 Ti 5 o 12 / TiN composite electrode material.

[0038] The electrochemical test was the same as in Example 1. The Li prepared by embodiment three method and proportioning 4 Ti 5 o 12 The battery made of / TiN composite material has a discharge capacity of 165.2mAh / g at 0.1C, 158.2mAh / g at 0.2C, and 135.1mAh / g at 0.5C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com