Preparation method for lithium ion battery anode piece, and anode piece prepared by the same

A technology of lithium-ion batteries and positive pole pieces, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as cost pollution, achieve the effects of reducing electrode polarization, reducing transmission distance, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

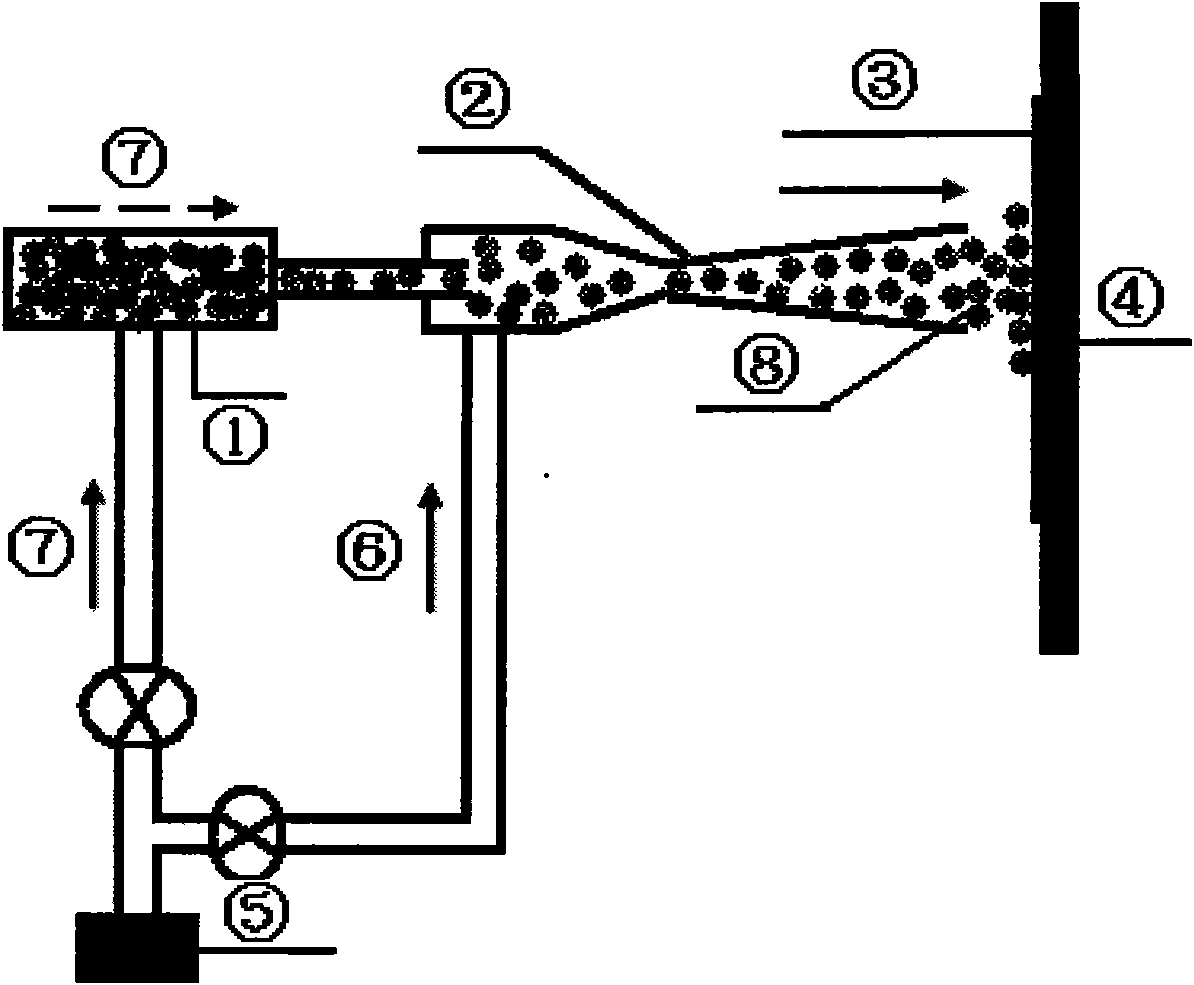

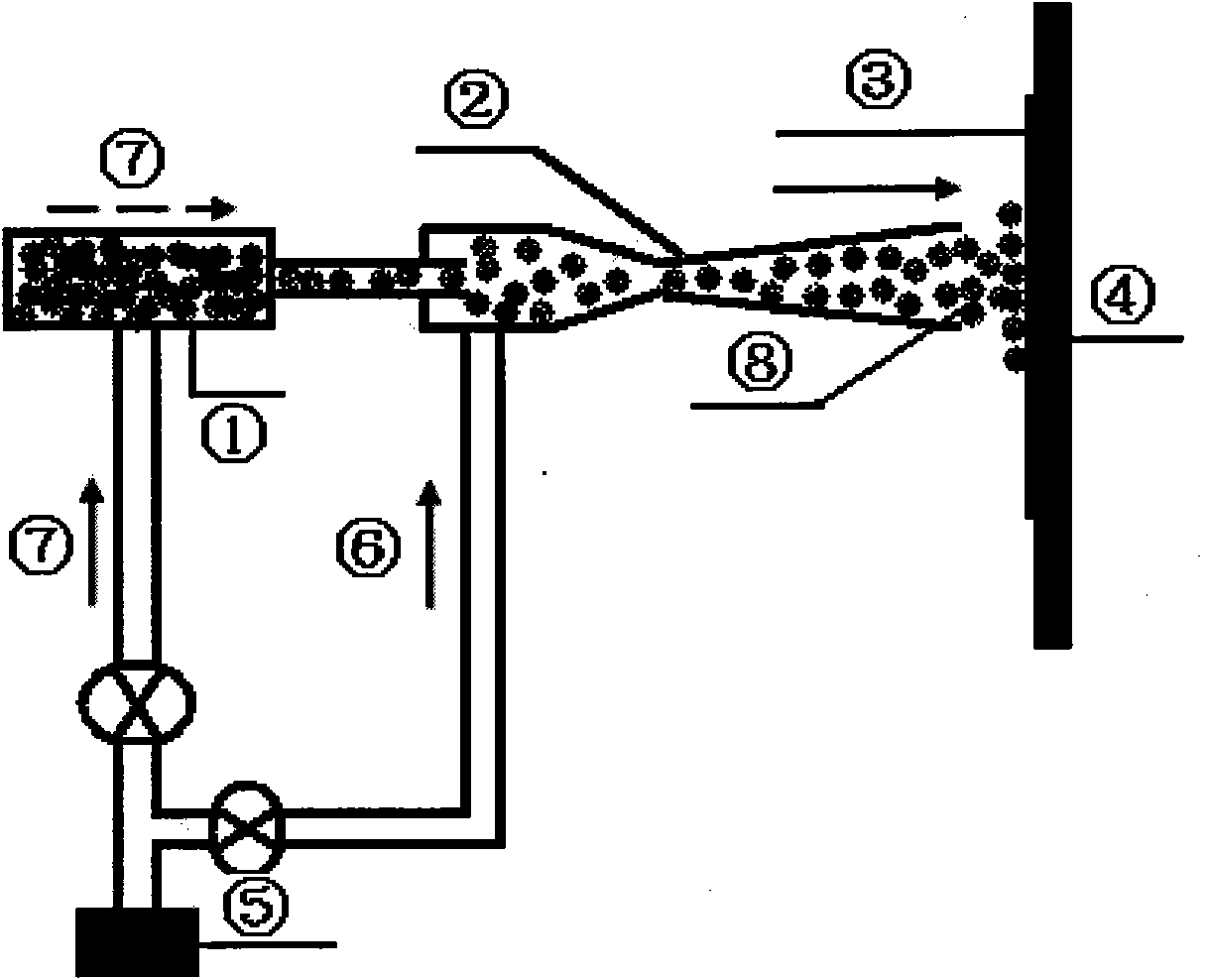

[0045] The process of making positive pole pieces of lithium-ion batteries by cold spraying technology includes the following steps:

[0046] (1) Use aluminum foil with a thickness of 20 μm as the current collector, wash it with alkali first, then clean it with deionized water and dry it, and place it flat on the working table of the spraying system.

[0047] (2), take D by mass percentage example 95% and 5% respectively 50 =10μm positive electrode active material LiFePO 4 and D 50 = 5 μm conductive agent copper powder, ultrasonically dispersed and mixed evenly. With He as the working gas, turn on the cold spraying device system, and put the uniformly mixed electrode material into the powder feeder of the cold spraying device system.

[0048] (3), LiFePO 4 The mixed electrode material particles with copper powder are sent into the spray gun through the powder feeder gas He in the powder feeder of the cold spray system, and then accelerated by the working gas He in the spra...

Embodiment 2

[0052] In this example, N 2 For the working gas, cold spraying is used to make the positive pole piece of lithium-ion battery, including the following steps:

[0053] (1) Use aluminum foil with a thickness of 20 μm as the current collector, wash it with alkali first, then clean it with deionized water and dry it, and place it flat on the working table of the spraying system.

[0054] (2), take D by mass percentage example 95% and 5% respectively 50 =10μm positive electrode active material LiFePO 4 and D 50 = 5 μm conductive agent copper powder, ultrasonically dispersed and mixed evenly. to N 2 For the working gas, turn on the cold spraying device system, and load the uniformly mixed electrode material into the powder feeder of the cold spraying device system.

[0055] (3), LiFePO 4 The mixed electrode material particles with copper powder are sent into the spray gun through the powder feed carrier gas He in the powder feeder of the cold spray device system, and then pass...

Embodiment 3

[0059] The process of making positive pole pieces of lithium-ion batteries by cold spraying technology includes the following steps:

[0060] (1) Use aluminum foil with a thickness of 20 μm as the current collector, wash it with alkali first, then clean it with deionized water and dry it, and place it flat on the working table of the spraying system.

[0061] (2), take D by mass percentage example 98% and 2% respectively 50 =10μm positive electrode active material LiFePO 4 and D 50 = 5 μm conductive agent copper powder, ultrasonically dispersed and mixed evenly. With He as the working gas, turn on the cold spraying device system, and put the uniformly mixed electrode material into the powder feeder of the cold spraying device system.

[0062] (3), LiFePO 4 The mixed electrode material particles with copper powder are sent into the spray gun through the powder feeder gas He in the powder feeder of the cold spray system, and then accelerated by the working gas He in the spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com