Lithium ion battery with high-rate charge-discharge performance

A charge-discharge performance, lithium-ion battery technology, applied in secondary batteries, battery electrodes, organic electrolytes, etc., can solve the problems of poor conductivity, difficult dispersion, large particle size specific surface area, etc., achieve high conductivity, increase volume The effect of energy density, buffer heat dissipation problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

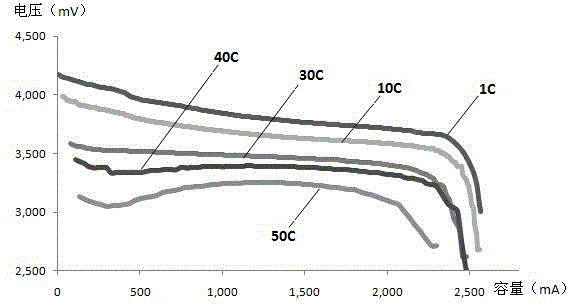

Image

Examples

Embodiment 1

[0023] A high rate performance lithium-ion battery described in this example uses lithium cobalt oxide as the positive electrode active material, the gram specific capacity of lithium cobalt oxide is 149mAh / g, and the first efficiency is 96.2%; the mesophase carbon microspheres are used as the negative electrode material. , the gram specific capacity is 320mAh / g, and the first efficiency is 94%.

[0024] Among them, the production of the positive pole piece is to first configure the binder PVDF (3wt%) and the solvent NMP (80wt%) into a glue solution, add graphene 2wt% to disperse well, and finally add the active material lithium cobaltate 95wt%, mix Make a slurry, adjust the viscosity, and then coat a pole piece on a 0.016mm aluminum foil with a density of 25mg / cm2 on both sides, and roll and cut to obtain a positive pole piece, with a compacted density of 1.8g / cm3;

[0025] The negative pole piece is made by first configuring 1.2wt% CMC and deionized water into a glue solutio...

Embodiment 2

[0028]The high rate performance lithium ion battery described in this example uses lithium cobalt oxide as the positive electrode active material, the gram specific capacity of lithium cobalt oxide is 145mAh / g, and the initial efficiency is 96.5%; using mesocarbon microspheres as the negative electrode material, g The specific capacity is 325mAh / g, and the first efficiency is 94.5%.

[0029] Among them, the production of the positive pole piece is to first configure the binder PVDF (2.5wt%) and the solvent NMP (80wt%) into a glue solution, add graphene 1.5wt% to disperse well, and finally add the active material lithium cobalt oxide 96wt% , mixed into a slurry, adjusted the viscosity, and then coated a pole piece on a 0.016mm aluminum foil with a double-sided surface density of 25mg / cm2, and rolled and cut to obtain a positive pole piece with a compacted density of 1.9g / cm3;

[0030] The production of the negative pole piece is to first configure 1.5wt% of CMC and deionized wa...

Embodiment 3

[0033] A high-rate performance lithium-ion battery described in this embodiment uses lithium cobalt oxide as the positive electrode active material, the gram specific capacity of lithium cobalt oxide is 150mAh / g, and the initial efficiency is 95.5%; the mesophase carbon microspheres are used as the negative electrode material. , the gram specific capacity is 320mAh / g, and the first efficiency is 94.1%.

[0034] Among them, the production of the positive pole piece is to first configure the binder PVDF (2.0wt%) and the solvent NMP (80wt%) into a glue solution, add graphene 1.0wt% to disperse well, and finally add the active material lithium cobalt oxide 97wt% , mixed into slurry, adjusted the viscosity, and then coated the pole piece on the 0.016mm aluminum foil, the double-sided surface density was 30mg / cm2, and rolled and cut to obtain the positive pole piece, the compaction density was 2.0g / cm3;

[0035] The negative pole piece is made by first configuring 1.5wt% CMC and dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com