Preparation method of low temperature graphite anode material for lithium ion battery

A lithium-ion battery, graphite negative electrode technology, applied in battery electrodes, graphene, circuits, etc., can solve the problems of inability to adapt to low-temperature operation of lithium-ion batteries, and can not effectively solve low-temperature lithium intercalation of graphite, etc. Small, highly isotropic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

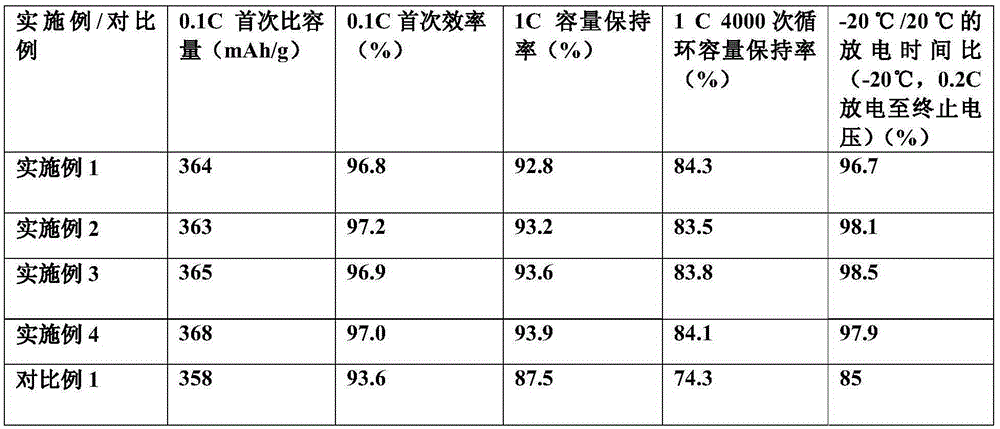

Embodiment 1

[0021] A method for preparing a low-temperature graphite negative electrode material for a lithium-ion battery, comprising the steps of:

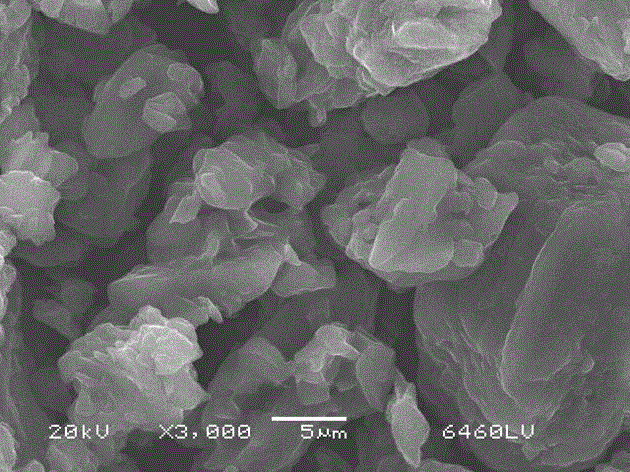

[0022] 1) Disperse graphite, dispersant, and the first carbon source in a water-soluble solvent, and mix them by ultrasonic waves for 0.5 to obtain a mixed solution; the first carbon source is formed by mixing glucose and phenolic resin in a mass ratio of 1:1; The graphite is natural graphite, particle size D50=10um; the water-soluble solvent is distilled water; the dispersant is polyvinylpyrrolidone.

[0023] 2) Grinding the mixed solution obtained in step (1) for 5 hours with a sand mill at a grinding speed of 500 r / min, and then adding a water-soluble solvent so that the solid mass content in the mixed solution is 5%;

[0024] 3) Dry the mixed solution ground in step (2) into powder using a spray dryer to obtain agglomerated granules. The air inlet temperature of the spray drying is 300°C, the air outlet temperature is 150°C, and the rot...

Embodiment 2

[0028] A method for preparing a low-temperature graphite negative electrode material for a lithium-ion battery, comprising the steps of:

[0029] 1) disperse graphite, dispersant, and the first carbon source in a water-soluble solvent, and mix them by ultrasonic waves for 2 hours to obtain a mixed solution; the first carbon source is formed by mixing glucose and phenolic resin in a mass ratio of 1:1; The graphite is natural graphite, particle size D50=1um; the water-soluble solvent is ethanol; the dispersant is sodium lauryl sulfate.

[0030] 2) Grinding the mixed solution obtained in step (1) with a sand mill for 1 hour at a grinding speed of 2500 r / min, and then adding a water-soluble solvent so that the solid mass content in the mixed solution is 20%;

[0031] 3) Dry the mixed solution ground in step (2) into powder using a spray dryer to obtain agglomerated granules. The air inlet temperature of the spray drying is 200°C, the outlet air temperature is 100°C, and the rotati...

Embodiment 3

[0035] A method for preparing a low-temperature graphite negative electrode material for a lithium-ion battery, comprising the steps of:

[0036] 1) Disperse graphite, dispersant, and the first carbon source in a water-soluble solvent, and mix them by ultrasonic waves for 1.5 hours to obtain a mixed liquid; the first carbon source is a mixture of polyvinyl alcohol and furfural resin in a mass ratio of 1:1 ; This graphite is nitrate artificial graphite, particle size D50=5um; This water-soluble solvent is that distilled water and ethylene glycol are mixed in molar ratio 1:1; This dispersant is polyvinylpyrrolidone and polyethyleneimine in molar ratio 1: 1 blended.

[0037] 2) Grinding the mixed solution obtained in step (1) for 3 hours with a sand mill at a grinding speed of 1500 r / min, and then adding a water-soluble solvent so that the solid mass content in the mixed solution is 10%;

[0038] 3) Dry the mixed solution ground in step (2) into powder using a spray dryer to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com