Negative electrode material of low-temperature lithium battery and preparation method of negative electrode material

A low-temperature lithium battery and negative electrode material technology, applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve the problems of poor electrical conductivity, poor low-temperature performance, and poor work performance, and achieve high isotropy, shrinkage, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

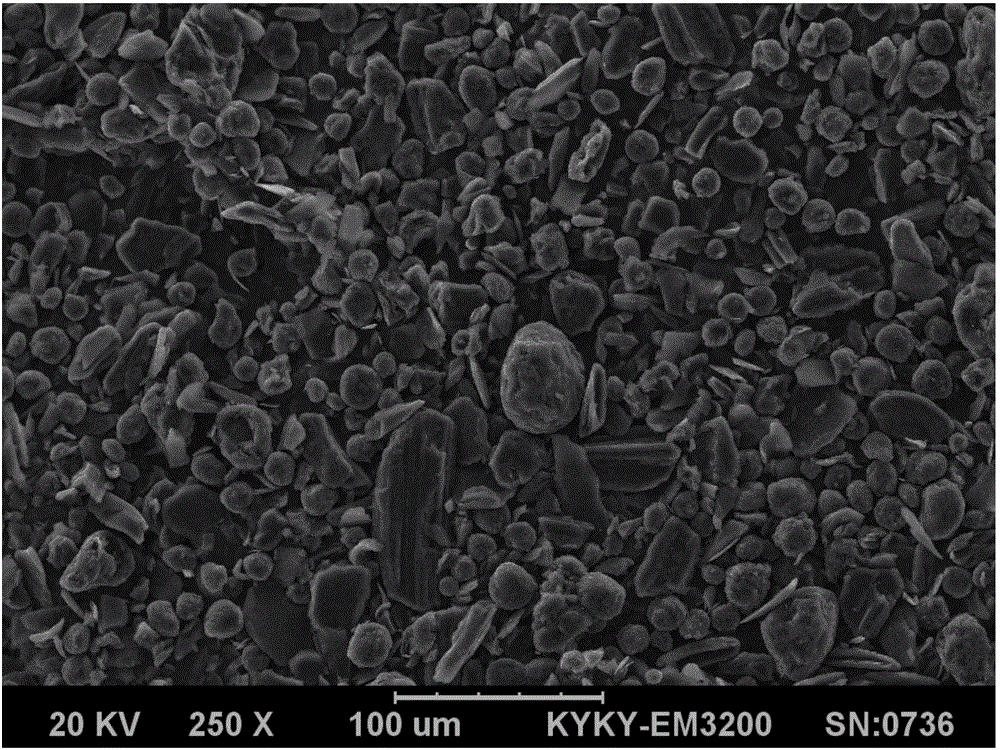

Image

Examples

Embodiment 1

[0036] A preparation method of a negative electrode material for a low-temperature lithium battery, the steps of which are as follows:

[0037] (1) Shaping and crushing

[0038] Add 30 parts of petroleum coke, 5 parts of needle coke, 30 parts of mesocarbon microspheres, and 30 parts of isotropic coke into a pulverizer for agitation and ball milling, and use wet agitation and ball milling to obtain mixed powder;

[0039] (2) intercalation micro-expansion

[0040] Put the mixed powder and concentrated nitric acid into the mixer and stir it ultrasonically for 0.5h, then separate the powder through a centrifuge, and wash the powder with pure water and ethanol until the pH value is 6; then put the powder at 85°C Drying for 10 hours After drying, place in a protective atmosphere at a temperature of 500°C for 10 hours; finally cool to room temperature to obtain micro-expanded graphite;

[0041] (3) Agglomeration and granulation

[0042] Add the micro-expanded graphite together wit...

Embodiment 2

[0050] A preparation method of a negative electrode material for a low-temperature lithium battery, the steps of which are as follows:

[0051] (1) Shaping and crushing

[0052] Add 40 parts of petroleum coke, 15 parts of needle coke, 20 parts of mesocarbon microspheres, and 20 parts of isotropic coke into a pulverizer for agitating ball mill, and use wet method agitating and ball milling to obtain mixed powder;

[0053] (2) intercalation micro-expansion

[0054] Add the mixed powder and perchloric acid into the mixer and stir it ultrasonically for 1 hour, then separate the powder through a centrifuge, and wash the powder with pure water and ethanol until the pH value is 8; then put the powder at 50°C After drying for 24 hours, place it in a protective atmosphere at a temperature of 900°C for 1 hour; finally cool to room temperature to obtain micro-expanded graphite;

[0055] (3) Agglomeration and granulation

[0056] Adding micro-expanded graphite together with coal tar an...

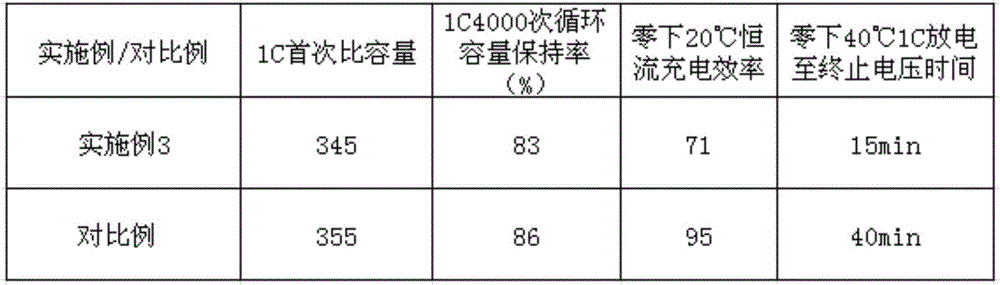

Embodiment 3

[0064] A preparation method of a negative electrode material for a low-temperature lithium battery, the steps of which are as follows:

[0065] (1) Shaping and crushing

[0066] Add 35 parts of petroleum coke, 10 parts of needle coke, 25 parts of mesocarbon microspheres, and 25 parts of isotropic coke into a pulverizer for agitation ball mill, and use wet agitation ball milling to obtain mixed powder;

[0067] (2) intercalation micro-expansion

[0068]Add the mixed powder and concentrated sulfuric acid into the mixer and stir it ultrasonically for 0.5h, then separate the powder through a centrifuge, and wash the powder with pure water and ethanol until the pH value is 7; then put the powder at 75°C After drying for 20 hours, place it in a protective atmosphere at a temperature of 700°C for 5 hours; finally cool to room temperature to obtain micro-expanded graphite;

[0069] (3) Agglomeration and granulation

[0070] Add micro-expanded graphite together with coal tar pitch a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com