A kind of ultrafine structure isotropic graphite and preparation method thereof

A technology of isotropic and isotropic coke, applied in the field of ultra-fine structure isotropic graphite and its preparation, which can solve the problems of high operating intensity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

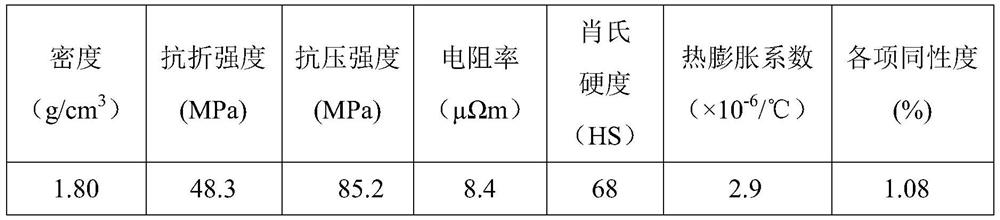

Embodiment 1

[0041] The ultra-fine structure isotropic graphite of the present invention is represented by weight percent. The ultra-fine structure isotropic graphite is composed of 55% isotropic coke as raw material, 20% high-purity artificial graphite, and 1.5% octadecanoic acid as a friction reducer. %, 23% of hard asphalt and 0.5% of auxiliary additives.

[0042] The auxiliary additive is a mixture of ferric oxide and ferric oxide, and the mixing mass ratio between the two is 5:1.

Embodiment 2

[0044] Embodiment 1 of the present invention is the preparation method of ultrafine structure isotropic graphite, the detailed steps of this preparation method are as follows:

[0045] 1) First, crush the raw material isotropic coke to <10 μm, high-purity artificial graphite to <10 μm, and hard pitch to <45 μm;

[0046] 2) Prepare isotropic coke, high-purity artificial graphite, hard pitch and other raw materials according to the batching ratio of ultra-fine structure isotropic graphite described in Example 1 after step 1);

[0047] 3) placing the other raw materials prepared in step 2) except the friction reducer in an airflow mixer and mixing them uniformly to obtain a mixture;

[0048] 4) Send the mixture obtained in step 3) into a kneader, add the prepared friction reducer, and then heat up to 180°C for kneading. The kneading time is 45 minutes, and the paste is obtained after kneading;

[0049] 5) Cool the paste obtained in step 4) to 130°C for 25 minutes to remove moist...

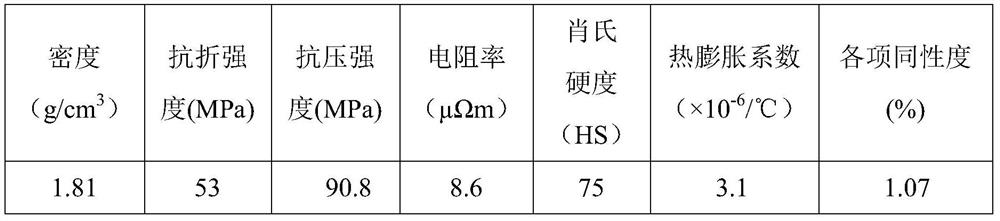

Embodiment 3

[0061] The ultra-fine structure isotropic graphite of the present invention is represented by weight percent. The ultra-fine structure isotropic graphite is composed of 58% isotropic coke as raw material, 15% high-purity artificial graphite, and 1.5% stearic acid as a friction reducer. %, 25% of hard asphalt and 0.5% of auxiliary additives.

[0062] The auxiliary additive is a mixture of ferric oxide and ferric oxide, and the mixing mass ratio between the two is 5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com