Production and producing apparatus for super fine cobalt powder by circulating technology

A technology of superfine cobalt powder and manufacturing method, applied in the field of cobalt powder manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

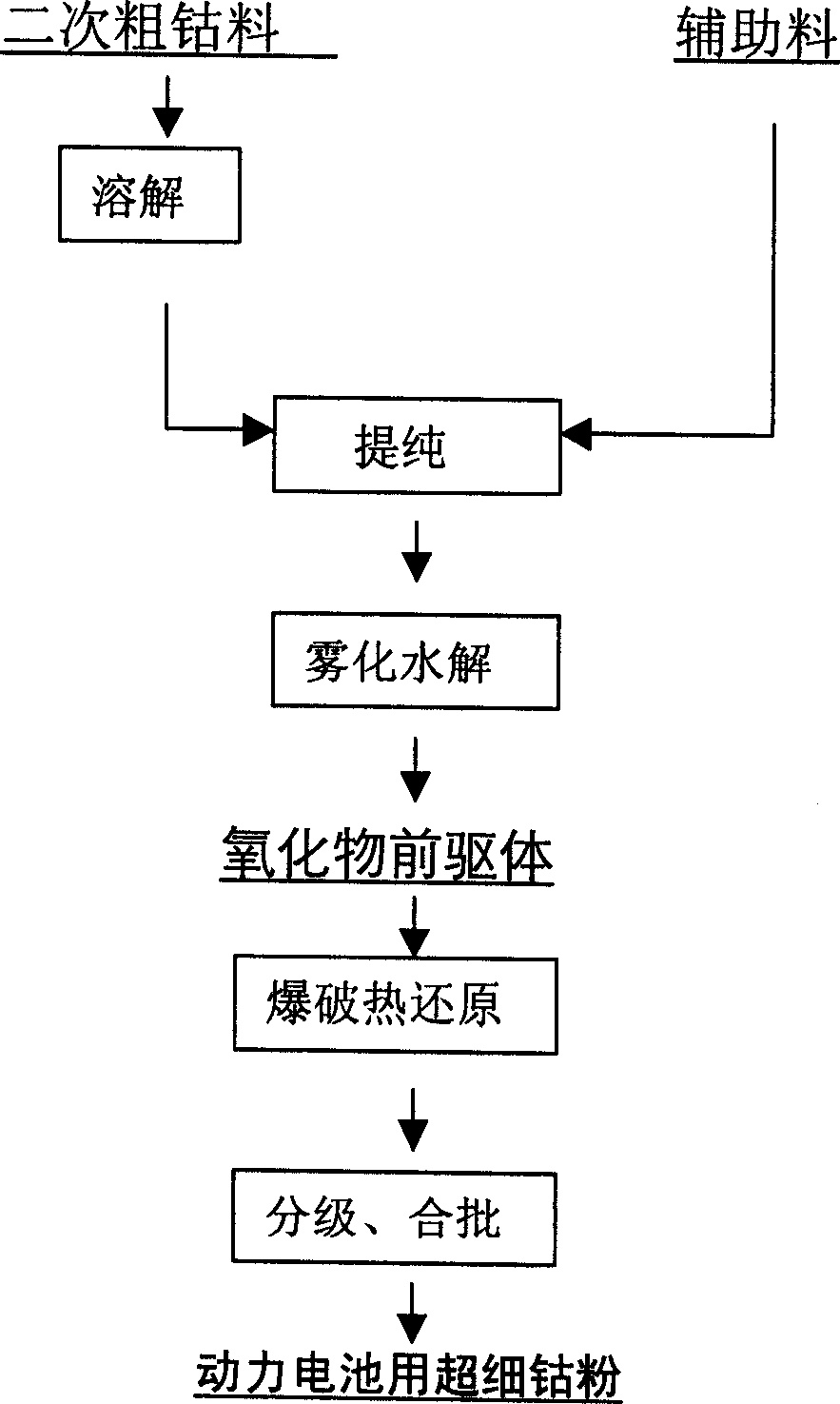

[0096] The process flow diagram of the manufacturing method of the cyclic technology of the present embodiment producing the ultrafine spherical shape is shown in figure 1 . The waste material (secondary coarse cobalt material) used in the present embodiment is:

[0097] 1. Waste nickel-hydrogen / nickel-cadmium batteries and waste materials and side materials in the production process. The cobalt content in such waste materials ranges from 1.0-15%; other components are Ni, Fe, Cd, Zn, etc., Ni: 10- 60%, Fe: 1-10%. Cd: 0.1-10%, Zn: 0.1-10%

[0098] 2. Waste lithium-ion batteries and waste materials and side materials in the production process, such waste materials contain 5-50% Co, and other components are Ni, Li, graphite, Mn, etc., Ni: 1-20%, Li : 1-20%. Graphite: 1-30%, Mn: 1-30%

[0099] Step 1: Dissolve

[0100] Add sulfuric acid or hydrochloric acid in described secondary cobalt-containing waste material or cobalt slag, its concentration is: sulfuric acid 10-98% or h...

Embodiment 2

[0176] This embodiment provides a manufacturing method for producing ultra-fine spheroids by cyclic technology. The waste material used in this embodiment is:

[0177] 1. Waste catalyst in the diamond industry, this kind of waste contains Co: 1-10%, Ni: 10-40%, Mn: 10-50%, trace Fe, Al, etc.

[0178] Step 1: Dissolve

[0179] Add hydrochloric acid in described secondary cobalt-containing waste material or cobalt slag, its concentration is 5-30%, (percentage by weight), and addition is different depending on raw material, is 100%-150% (percentage by weight) (for waste material by weight percentage) The total amount of all metals is used to calculate the stoichiometric equivalent), so that it is dissolved, and the cobalt in the waste forms soluble cobalt chloride CoCl 2 ; other components in the waste are also dissolved in hydrochloric acid to form soluble chlorides, thus forming crude cobalt chloride CoCl 2 solution;

[0180] Since the raw materials used in this example hav...

Embodiment 3

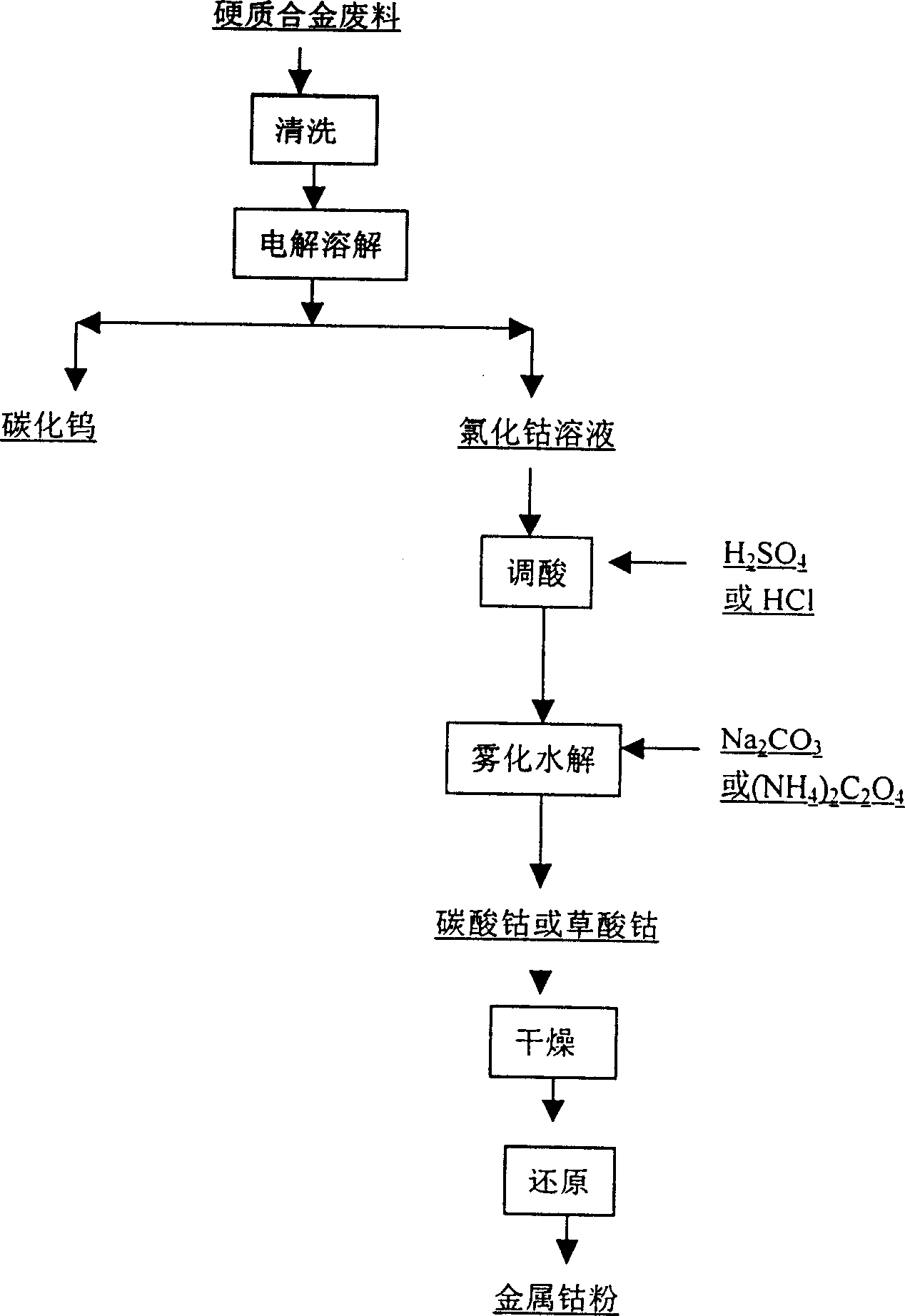

[0225] The secondary raw material used in this embodiment is cemented carbide waste block, and its process flow chart is shown in image 3 As shown, the dissolution process uses the electrolytic dissolution method.

[0226] A hydrochloric acid solution with a concentration of 1.5-5 gram equivalents / liter is injected into an electrolytic cell, and an anode basket made of polyvinyl chloride orifice plate is arranged therein, and cemented carbide waste blocks are put into the basket as an anode. A conductive plate is inserted as a cathode in the electrolytic cell, which may be a graphite plate, preferably a titanium metal plate. The cathode and anode are connected to a DC power source. The cell voltage is controlled at 1.5-4.0V, and the current density is 50-300 ampere / meter 2 During the electrolysis process, the concentration of hydrochloric acid in the electrolytic cell is always kept at 1.5-5 g equivalent / liter, and when the concentration drops during the electrolysis proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com