Biological adsorbent, preparation method thereof, and application thereof to removal of methylene blue dye of waste water

A methylene blue dye and biosorbent technology, which is applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc., can solve the problem of no use value of biomass slag, achieve high dye removal efficiency and excellent preparation process Simple, high removal rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

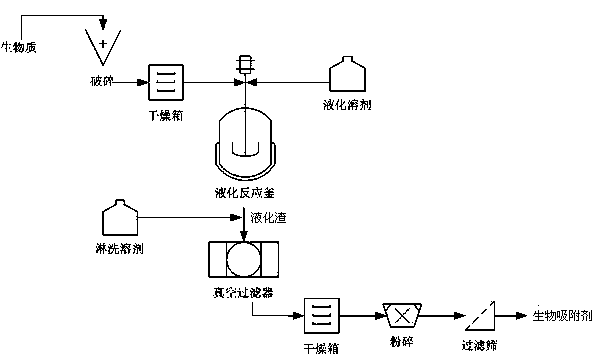

[0031] Crush the rice straw to 0.2-0.9 mm, then dry it at a constant temperature of 105°C for 24 hours, then mix 3.94g of dried rice straw with 100mL of ethanol, and place it in a high-pressure reactor for liquefaction reaction. The liquefaction pressure is 20.0 MPa and the temperature is 350°C. , and stay at 350°C for 10 minutes; finally, the liquefied slag obtained from the above liquefaction reaction was rinsed with acetone, vacuum filtered, dried, crushed, and passed through a 200-mesh sieve to obtain liquefied rice straw residue, that is, a biosorbent. Specific process such as figure 1 shown.

[0032] Add the above 10 mg of liquefied rice straw dregs to 20 mL of simulated wastewater with an initial concentration of methylene blue of 100 mg / L. The shaking reaction temperature is 30°C, the shaking reaction speed is 160 rpm, and the shaking reaction time is 12 hours. Shake each group of wastewater after the reaction to complete the removal of methylene blue in the wastewate...

Embodiment 2

[0035]The chlorella was crushed to 0.2-0.9 mm, and then dried at a constant temperature of 105 °C for 24 hours, then 3.94 g of dried chlorella was mixed with 100 mL of ethanol, and placed in a high-pressure reactor for liquefaction reaction. The liquefaction pressure was 5.0 MPa and the temperature was 350°C, and stay at 350°C for 30 minutes; finally, the liquefied slag obtained from the above liquefaction reaction is rinsed with acetone, vacuum filtered, dried, crushed, and passed through a 200-mesh sieve to obtain liquefied chlorella residue, which is a biosorbent.

[0036] Add 10 mg of the liquefied chlorella residue above to 20 mL of simulated wastewater with an initial methylene blue concentration of 100 mg / L. The shaking reaction temperature is 30 °C, the shaking reaction speed is 160 rpm, and the shaking reaction time is 12 h. Liquid separation of each group of wastewater after the above shaking reaction, to complete the removal of methylene blue in the wastewater. The ...

Embodiment 3

[0039] Crush the rice husks to 0.2-0.9mm, then dry at a constant temperature of 105°C for 24 hours, then mix 3.94g of dried rice husks with 100mL of water, and place them in a high-pressure reactor for liquefaction reaction. The liquefaction pressure is 10.0 MPa and the temperature is 260°C. , and stay at 260°C for 20 minutes; after the liquefaction is completed, the liquefied slag obtained from the above liquefaction reaction is rinsed with distilled water, vacuum filtered, dried, crushed, and passed through a 200-mesh sieve to obtain liquefied rice husk residue, that is, a biosorbent.

[0040] Add the above 10 mg of liquefied rice husk residue to 20 mL of simulated wastewater with an initial concentration of methylene blue of 100 mg / L. The shaking reaction temperature is 30°C, the shaking reaction speed is 180 rpm, and the shaking reaction time is 12 hours. After the reaction is completed, the solid-liquid separation Each group of wastewater after the above shaking reaction h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com