High-voltage cathode material Li delta Co(1-x)MgxO2@AlF3 of lithium ion battery and preparation method of high-voltage cathode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor electrochemical performance, and achieve the effects of improving electrical conductivity, good intercalation and deintercalation, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

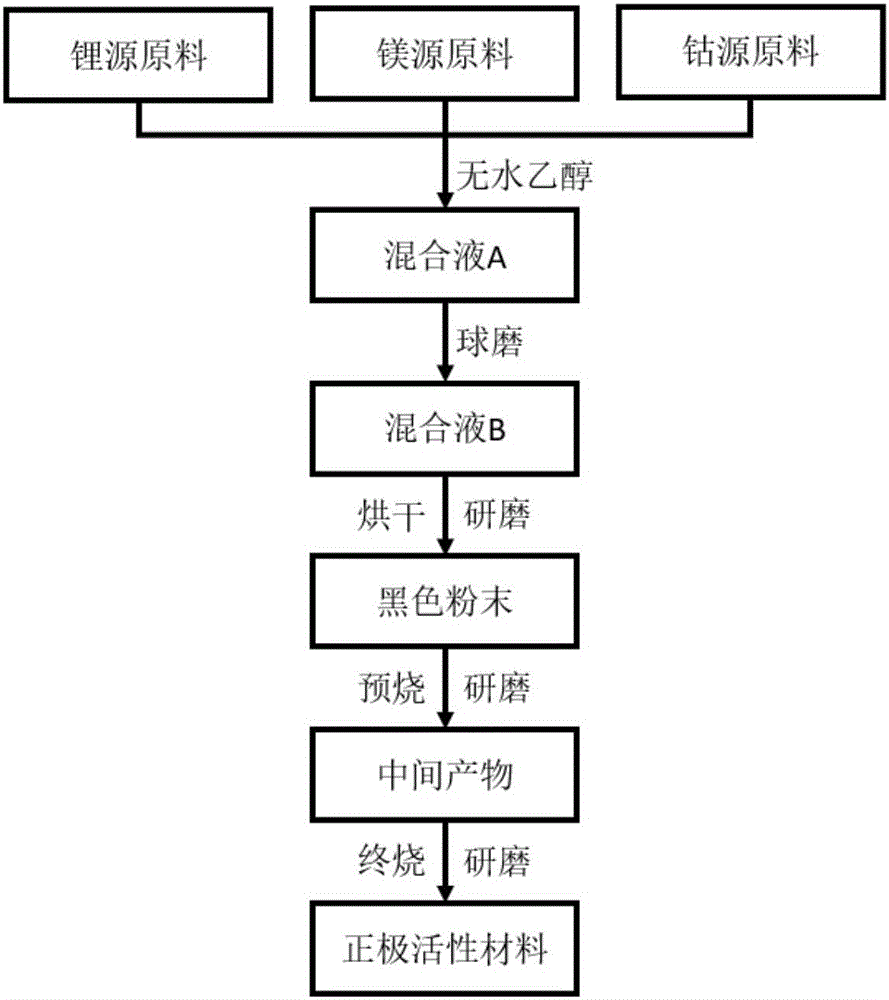

Method used

Image

Examples

Embodiment 1

[0034] Weigh 0.0525mol (3.8792g) of lithium carbonate, 0.0323mol (7.7858g) of cobalt tetroxide, 0.0030mol (0.7692g) of magnesium nitrate hexahydrate and 15mL of absolute ethanol into a ball mill jar to obtain a mixed solution A;

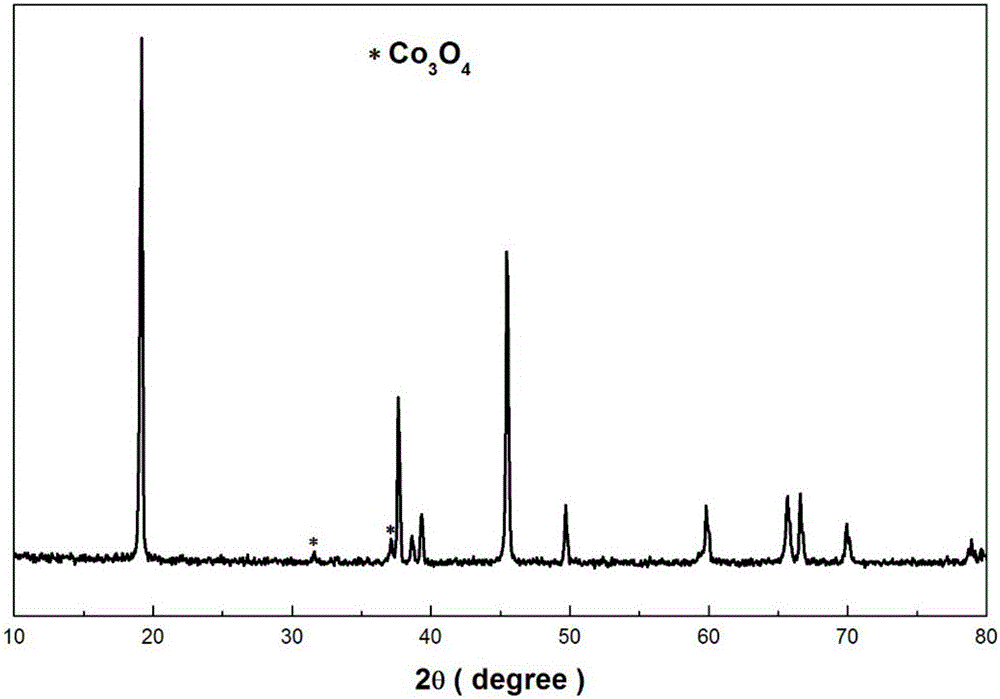

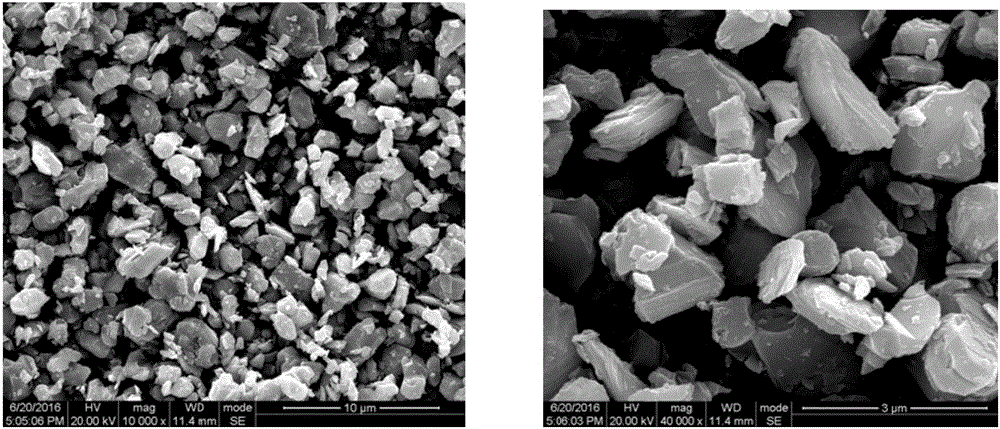

[0035] After mixing the mixed solution A with 100g ball milling beads, they were ball milled together for 12 hours to obtain the mixed solution B; the mixed solution B was dried at 105°C for 24 hours to obtain a black powder; the obtained black powder was placed in a muffle furnace, The heating rate is 3°C / min, and it is kept at 750°C for 10 hours. After the heat preservation is over, it is cooled with the furnace. After the cooling is completed, take it out and grind it to obtain the intermediate product of pre-sintered material; put the intermediate product of pre-sintered material in the muffle furnace , the heating rate is still 3°C / min, and keep warm for 12 hours after reaching 920°C, and then cool with the furnace. 1.05 co 0.97 Mg 0.03 o 2 ;...

Embodiment 2

[0039] Weigh 0.1050mol (7.7584g) of lithium carbonate, 0.0646mol (15.5717g) of cobalt tetroxide, 0.0060mol (1.5384g) of magnesium nitrate hexahydrate and 25mL of absolute ethanol into a ball mill jar to obtain a mixed solution A;

[0040] After mixing the mixed solution A with 150g ball milling beads, they were ball milled together for 12 hours to obtain the mixed solution B; the mixed solution B was dried at 105°C for 24 hours to obtain a black powder; the obtained black powder was placed in a muffle furnace, The heating rate is 3°C / min, and it is kept at 750°C for 12 hours. After the heat preservation is over, it is cooled with the furnace. After the cooling is completed, it is taken out and ground to obtain the intermediate product of the calcined material; the intermediate product of the calcined material is placed in the muffle furnace , the heating rate is 2°C / min, and the temperature is kept at 950°C for 12 hours. After the heat preservation is completed, it is cooled wi...

Embodiment 3

[0043] Weigh 0.0525mol (3.8792g) of lithium carbonate, 0.0323mol (7.7858g) of cobalt tetroxide, 0.0030mol (0.7692g) of magnesium nitrate hexahydrate and 15mL of absolute ethanol into a ball mill jar to obtain a mixed solution A;

[0044] After mixing the mixed solution A with 100g ball milling beads, they were ball milled together for 12 hours to obtain the mixed solution B; the mixed solution B was dried at 105°C for 24 hours to obtain a black powder; the obtained black powder was placed in a muffle furnace, The heating rate is 3°C / min, and it is kept at 750°C for 10 hours. After the heat preservation is over, it is cooled with the furnace. After the cooling is completed, take it out and grind it to obtain the intermediate product of pre-sintered material; put the intermediate product of pre-sintered material in the muffle furnace , the heating rate is still 3°C / min, keep warm for 12 hours after reaching 1000°C, and then cool with the furnace. 1.05 co 0.97 Mg 0.03 o2 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com