Manufacturing method of negative plate of safety lithium-ion battery

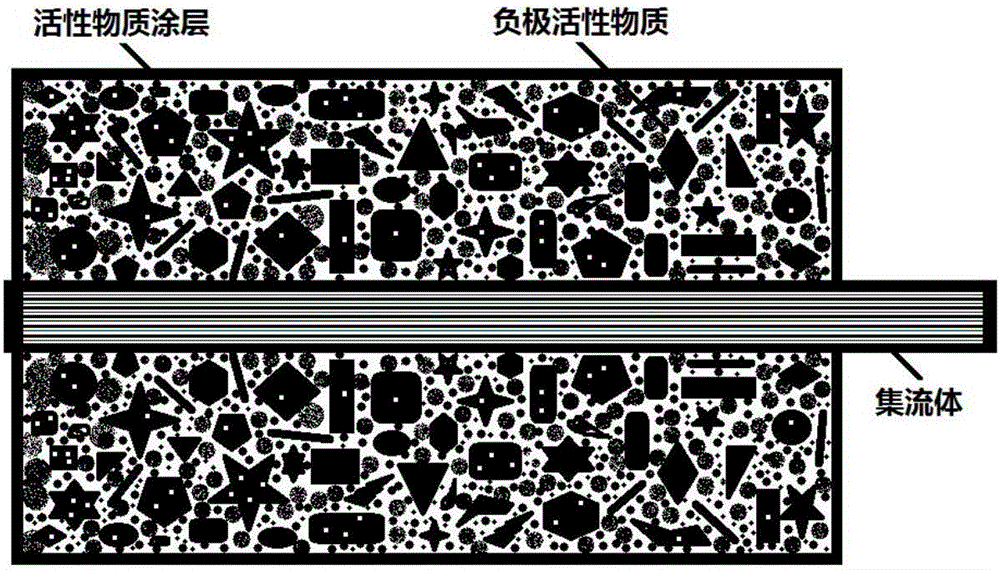

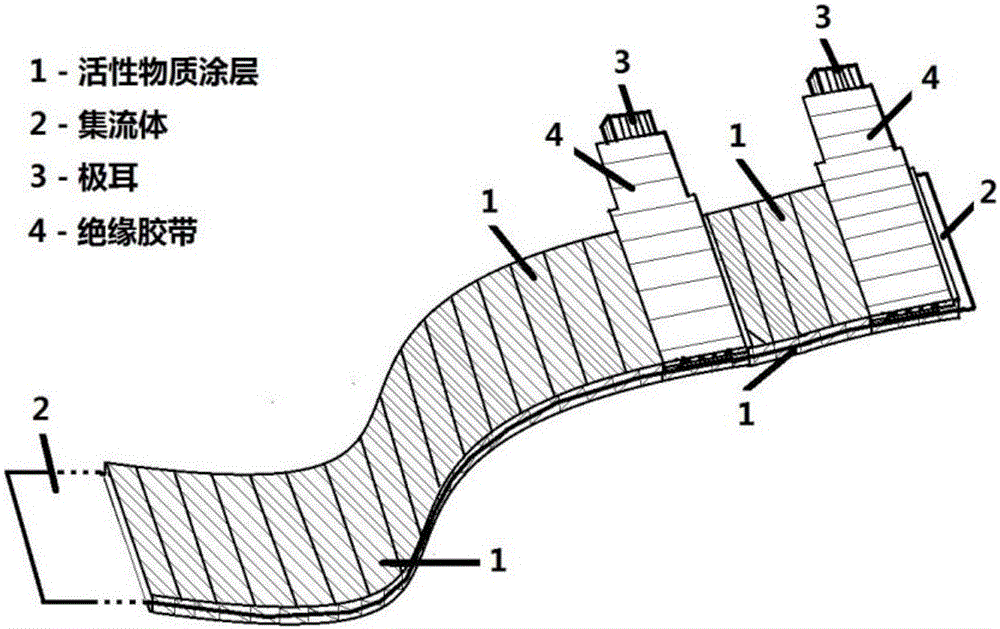

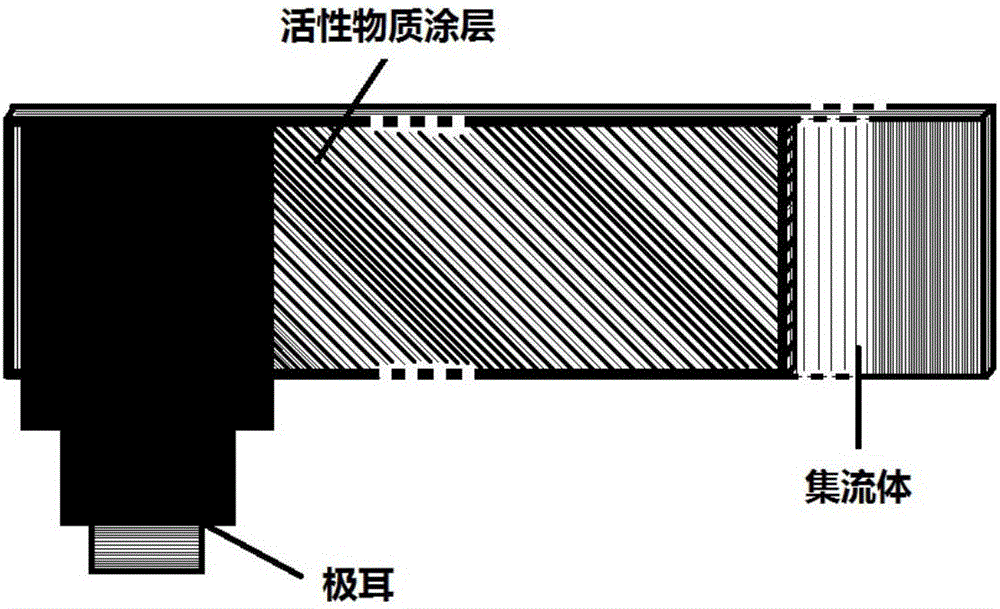

A manufacturing method, lithium ion technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., to achieve high filling density, excellent charge and discharge performance, and good filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for manufacturing a safe lithium-ion battery negative plate, comprising the following steps and process conditions:

[0054] The first step is negative pole active material graphite / activated carbon composite material: SP presses the mass ratio of 1:0.002, and ball mill mixes 0.5 hour, obtains negative pole active material mixture A; With negative pole additive graphene B; According to the mass ratio of A:B is The ratio of 1:0.005 was ball milled for 4 hours and mixed evenly to make negative electrode active material mixture C;

[0055] In the second step, the CMC accounting for 1% of the mass of the mixture C is formulated with distilled water to form a 0.5% aqueous solution at a mass percentage concentration of 0.5% at a constant temperature of 30° C. and stirred in vacuum for 0.5 hours, adding 2% of the SBR accounting for the mass of the C substance in 3 or 4 or 5 times, At the same time, add NMP solvent accounting for 1% of the water mass of the CMC solutio...

Embodiment 2

[0061] A method for manufacturing a safe lithium-ion battery negative plate, comprising the following steps and process conditions:

[0062] In the first step, the negative electrode active material graphite / activated carbon composite material: SP is mixed by ball milling for 1 hour at a mass ratio of 1:0.004 to obtain the negative electrode active material mixture A; the carbon nanotubes B are respectively according to the mass ratio of A:B: 1:0.004 ratio, ball milled for 1 hour and mixed evenly to make negative electrode active material mixture C;

[0063] In the second step, the CMC accounting for 2% of the mass of C is formulated with twice-distilled water to form a 1% aqueous solution with a concentration of 1% by mass, kept at a constant temperature of 35° C., and stirred in vacuum for 1 hour, and then added SBR accounting for 4% of the mass of C in 3 or 4 or 5 times. At the same time, add NMP accounting for 2% of the water content of the CMC solution, keep the temperatu...

Embodiment 3

[0069] A method for manufacturing a safe lithium-ion battery negative plate, comprising the following steps and process conditions:

[0070] In the first step, graphite / activated carbon composite material: SP is mixed by ball milling for 1.5 hours at a mass ratio of 1:0.006 to obtain negative electrode active material mixture A; the mixture B of graphene and carbon nanotubes mixed in equal mass ratio is according to A:B The mass ratio is: a ratio of 1:0.003, ball milled for 2 hours and mixed evenly to make negative electrode active material mixture C;

[0071] The second step will account for the first step to obtain CMC with 3% of the mass of C, and use pure water to prepare an aqueous solution with a concentration of 2.0% by mass, keep the temperature at 40°C, and stir in vacuum for 2 hours, and add 6% of the mass of C in 3 or 4 or 5 times. % SBR, while adding NMP accounting for 3% of the water content of the CMC solution, 40 ° C constant temperature, vacuum stirring, 3 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com