Aluminum oxide solid diaphragm, preparing method of aluminum oxide solid diaphragm, electrochemical battery or capacitor

A kind of aluminum oxide powder and aluminum oxide technology, applied in the field of electrochemistry, can solve the problems of difficulty in meeting the safety performance and high rate performance requirements of power batteries, poor electrolyte wettability, poor high rate performance, etc., and achieve high current Charge-discharge performance, improved safety, effects of suitable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing an alumina solid diaphragm, comprising the following steps:

[0038] (1) Mix alumina powder with an average particle size of 0.1 μm and a purity of 99.99% with pore-forming agent ethylenediaminetetraacetic acid (EDTA) at a mass ratio of 4:6, and ball mill for 6 hours to form a mixed powder;

[0039] (2) Pass the obtained mixed powder through a 1000-mesh nylon sieve to obtain dispersed mixed powder;

[0040] (3) Dry press the obtained dispersed mixed powder under a pressure of 10 MPa to obtain a green body;

[0041] (4) Put the obtained biscuit in the sintering furnace. The sintering furnace is in the air flow of 0.5L / min. First, the temperature is raised to 800°C at a rate of 1°C / min. Raise the temperature to 1300°C, keep the temperature for 2 hours, and then cool to obtain a solid aluminum oxide diaphragm with a thickness of 0.1 mm.

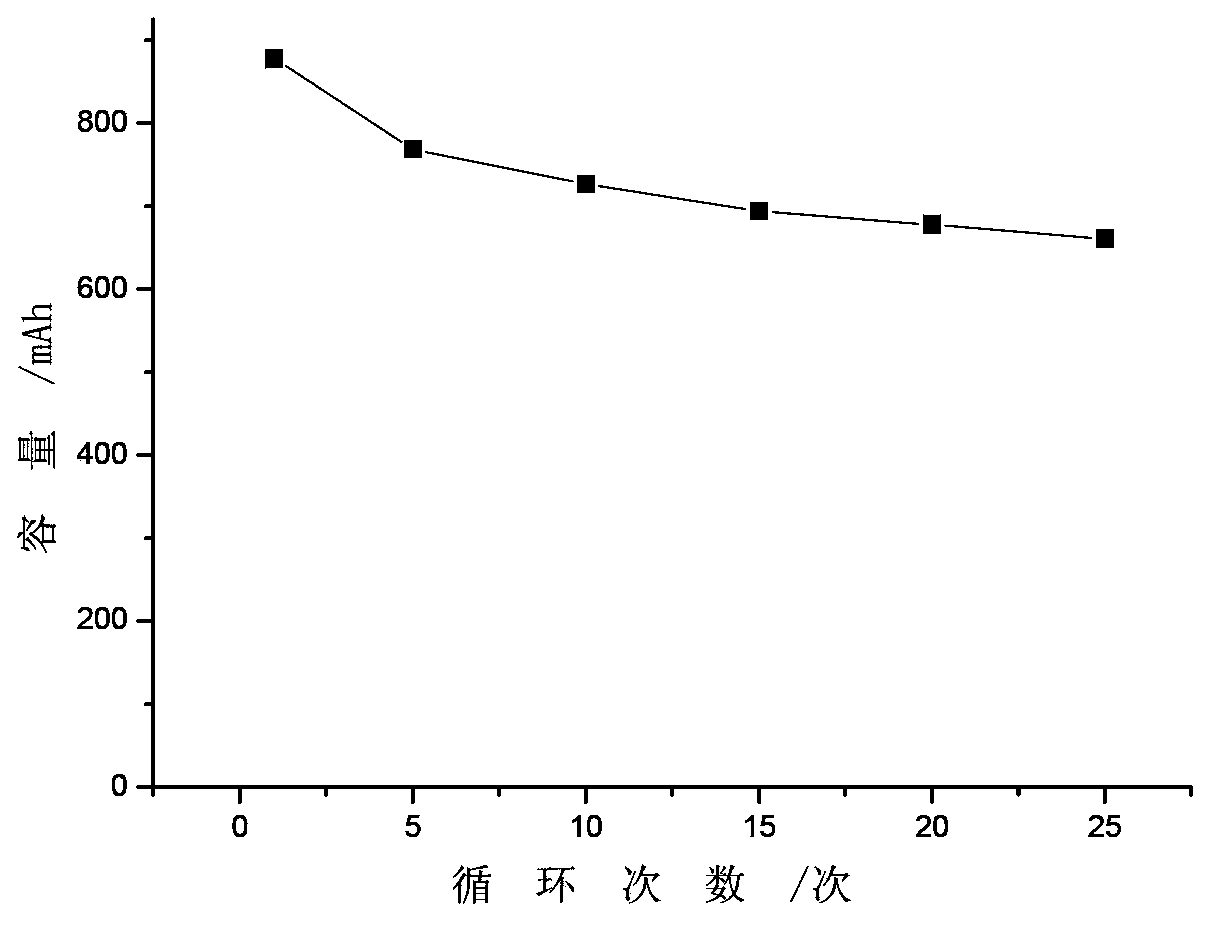

[0042] The alumina solid diaphragm prepared in this example was tested for porosity, pore size and air permeabi...

Embodiment 2

[0044] A method for preparing an alumina solid diaphragm, comprising the following steps:

[0045] (1) Mix alumina powder with an average particle size of 0.5 μm and a purity of 99.99% with pore-forming agent ethylenediaminetetraacetic acid (EDTA) at a mass ratio of 1:1, and ball mill for 12 hours to form a mixed powder;

[0046] (2) Pass the obtained mixed powder through a 2000-mesh nylon sieve to obtain dispersed mixed powder;

[0047] (3) Cold isostatic pressing of the obtained dispersed mixed powder under a pressure of 100 MPa to obtain a green body;

[0048] (4) Put the obtained biscuit in a sintering furnace, and the sintering furnace is in an oxygen flow of 2L / min, and the temperature is raised to 900°C at a rate of 3°C / min, and after holding for 4 hours, continue to heat up at a rate of 10°C / min Heat to 1500°C, keep warm for 3 hours, and then cool to obtain a solid aluminum oxide diaphragm with a thickness of 0.2mm.

[0049] The alumina solid diaphragm prepared in th...

Embodiment 3

[0051] A method for preparing an alumina solid diaphragm, comprising the following steps:

[0052](1) Mix alumina powder with an average particle size of 0.8 μm and a purity of 99.999% with pore-forming agent ethylenediaminetetraacetic acid (EDTA) at a mass ratio of 7:3, and ball mill for 24 hours to form a mixed powder;

[0053] (2) Pass the obtained mixed powder through a 3000-mesh nylon sieve to obtain dispersed mixed powder;

[0054] (3) Dry press the obtained dispersed mixed powder under a pressure of 20 MPa to obtain a green body;

[0055] (4) Place the obtained biscuit in a sintering furnace, and the sintering furnace is in an oxygen flow of 4L / min, and the temperature is raised to 1000°C at a rate of 7°C / min, and after holding for 8 hours, continue to heat up at a rate of 15°C / min To 1700°C, keep warm for 5 hours, and then cool to obtain a solid aluminum oxide diaphragm with a thickness of 0.4mm.

[0056] The alumina solid diaphragm prepared in this example was teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com