Ultra-light conductive current collector

A technology of current collectors and conductive agents, applied in the field of ultra-light conductive current collectors, can solve the problems of not meeting the requirements of lightweight batteries, increasing the thickness of current collectors, and increasing the quality of current collectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

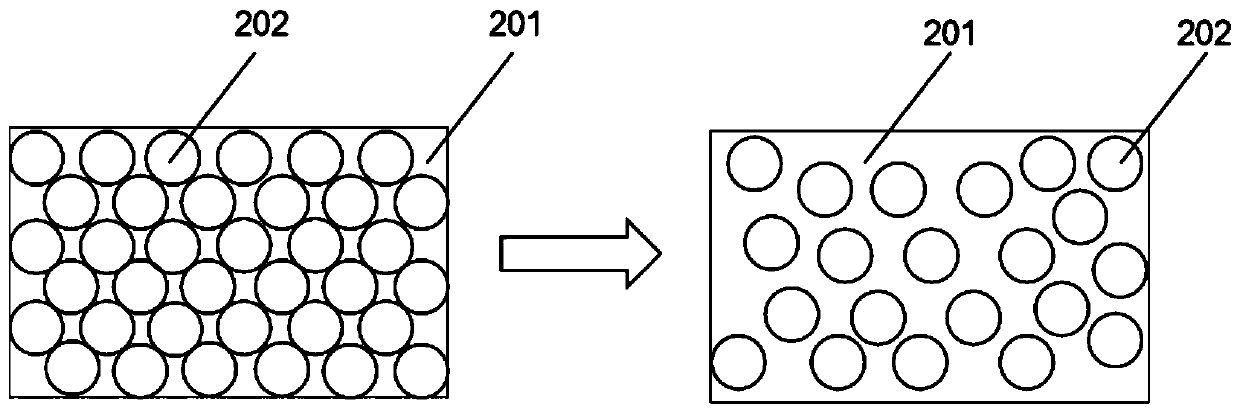

[0044](1) Preparation of polyethylene PTC plastics: setting the Curie temperature point to be 85°C, setting the model ingredients of low-density polyethylene and aluminum metal powder according to the Curie temperature point, wherein the low-density polyethylene mass accounts for 70% of the percentage, The mass of aluminum metal powder accounts for 30%, and the content of pure aluminum is not less than 98%. First add aluminum metal powder into the internal mixer with the temperature set at 185°C, set the speed at 5 rpm, then slowly add polyethylene particles for full mixing, and increase the speed of the internal mixer to 30 after the polyethylene feeding is completed. revolutions per minute, banburying time 40 minutes, to obtain polyethylene PTC plastics.

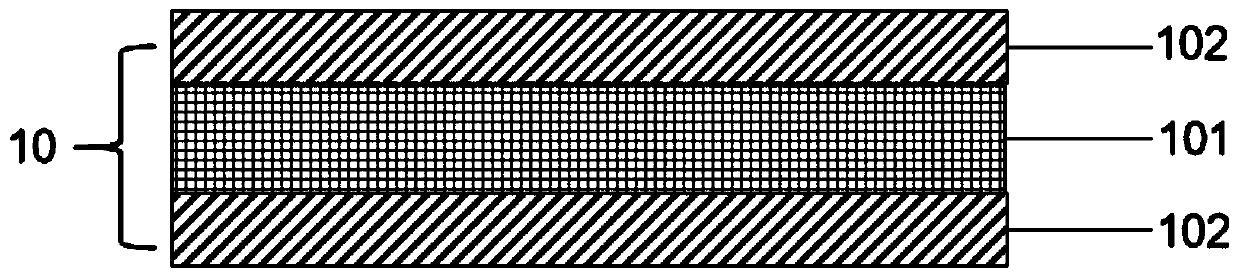

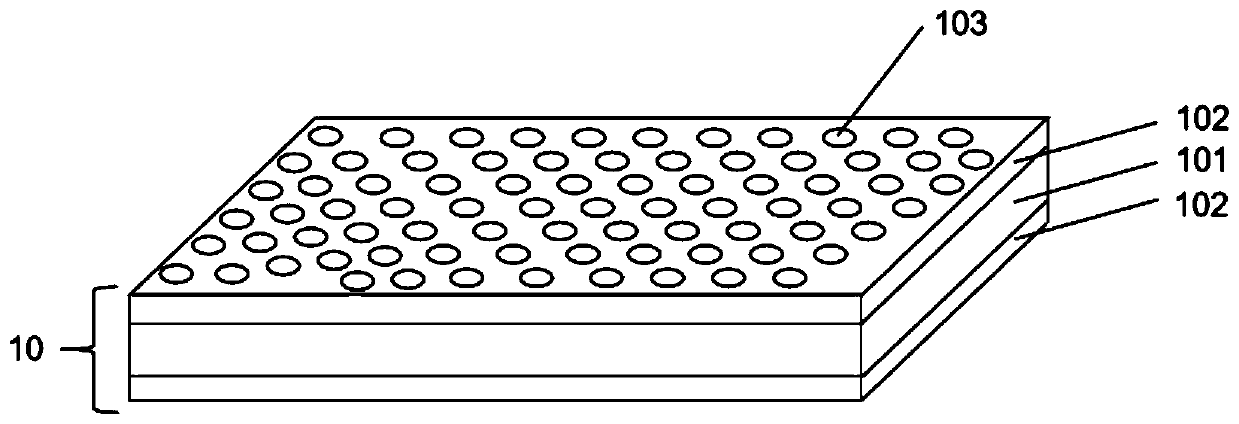

[0045] (2) Preparation of polyethylene PTC plastic film: the polyethylene PTC plastic obtained above is rolled by an open mill to obtain a polymer PTC plastic film coil with a thickness of 40 μm; Vinyl PTC plastic film. ...

Embodiment 2

[0050] (1) Preparation of polypropylene PTC plastic: set the Curie temperature point to 100°C, set the model ingredients of polypropylene and aluminum metal powder according to the Curie temperature point, wherein the mass of polypropylene accounts for 80%, and the mass of aluminum metal powder The percentage is 20%, and the pure aluminum content is not less than 95%. In the internal mixer whose temperature is set at 200°C, inert gas is introduced first, then polypropylene particles are added, and the speed is set at 15 rpm. After maintaining this state for 30 minutes, aluminum metal powder is slowly added, and the speed is increased to 60. revolutions per minute, banburying time 50 minutes, to obtain polypropylene PTC plastics.

[0051] (2) Preparation of polypropylene PTC plastic film: rolling the above-mentioned polypropylene PTC plastic through an open mill to obtain a polymer PTC plastic film coil with a thickness of 60 μm; Acrylic PTC plastic film.

[0052] (3) Cleanin...

Embodiment 3

[0056] (1) Preparation of polyimide PTC plastic: set the Curie temperature point to 400°C, and set the model ingredients of polyimide and copper metal powder according to the Curie temperature point, wherein the mass of polyimide accounts for 80% %, the mass of copper metal powder accounts for 20%, and the pure copper content is not less than 98%. First pass argon gas into the internal mixer with the temperature set at 600°C, then add polyimide particles, and set the speed at 20 rpm. After maintaining this state for 60 minutes, slowly add copper metal powder, and increase the speed to 60 rpm, banburying time 60 minutes, to obtain polyimide PTC plastics.

[0057] (2) Prepare polyimide PTC plastic film: the polyimide PTC plastic of above-mentioned gain is rolled by open mill, obtains the polymer PTC plastic film coil material that thickness is 75 μ m; A polyimide PTC plastic film of 12 μm was obtained.

[0058] (3) Cleaning polyimide PTC plastic film: the polyimide PTC plastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com