Phosphous plaster double-row-hole energy-saving building brick and all-dry production method thereof

A phosphogypsum, double-row hole technology, applied in building components, building materials, ceramic molding machines, etc., can solve the problems of reduced use area, no phosphogypsum, poor energy-saving effect, etc., and achieves convenient manual operation, weight reduction, and energy saving. The effect of water in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

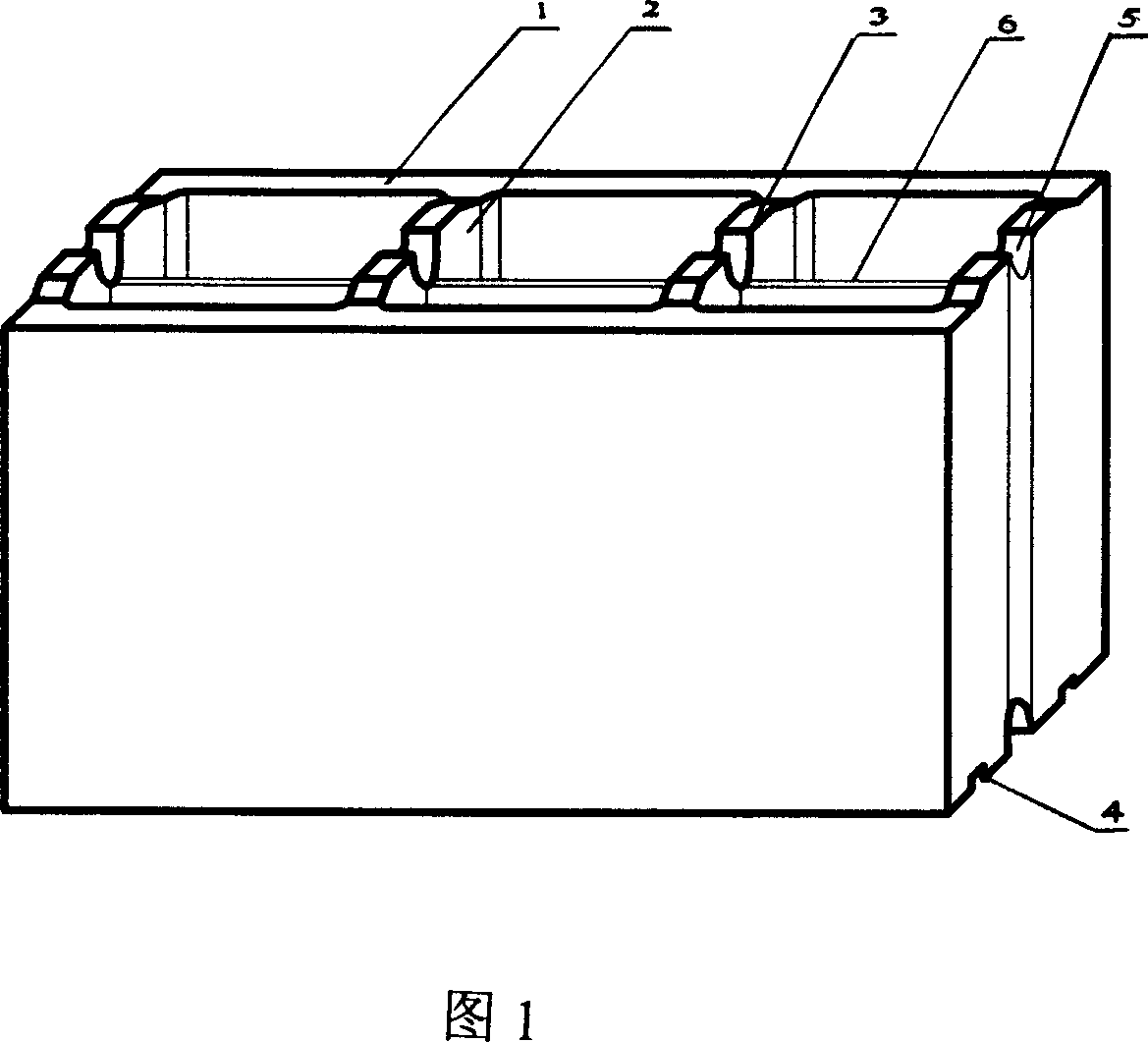

[0029] Embodiment 1: As shown in Figure 1, a phosphogypsum block with double rows of holes is obtained by using phosphogypsum as the basic raw material through high-pressure molding, and its main body includes a main wall 1, ribs 2 and ribs 3; Two layers arranged in parallel are connected by four ribs 2 , and the ribs 3 are higher than the main wall 1 to form double ribs; the bottom of the ribs 2 is provided with a groove 4 matching the ribs 3 .

Embodiment 2

[0030] Embodiment 2: The difference from Embodiment 1 is that the rib 3 is also provided with a semicircular hole 5 .

Embodiment 3

[0031] Embodiment 3: On the basis of Embodiment 1 and / or Embodiment 2, a hard polystyrene board 6 partition connected to the ribs 2 is further provided between the parallel main walls 1 .

[0032] The full-dry production method of the phosphogypsum double-row hole block comprises the following steps:

[0033] 1) Raw material treatment: use the dry calcination method (180°C-500°C, staged treatment) to discard the attached water, so that the crystal water content is less than 15%; at the same time, remove phosphorus, acid and other harmful substances in the discarded phosphogypsum , the fluorine content is ≤0.3mg / L, which meets the requirement that the fluorine content of environmental protection building materials is ≤1, and the radioactivity ratio is 0.25.

[0034] 2) Add 15-25% water-soluble glue to the hemihydrate phosphogypsum (the water-sol is made by combining sodium silicate with water, the content of sodium silicate is 12-25%, and the pH is 7); Mix the gypsum evenly; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com