High-strength PE electric conduit and preparation method thereof

A high-strength, electric technology, applied in the direction of general water supply saving, coating, polyurea/polyurethane coating, etc., can solve the requirements of high compressive performance and impact resistance of power tubes, affect the service life of power tubes, and poor mechanical strength And other problems, to achieve good shock absorption, long service life, improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

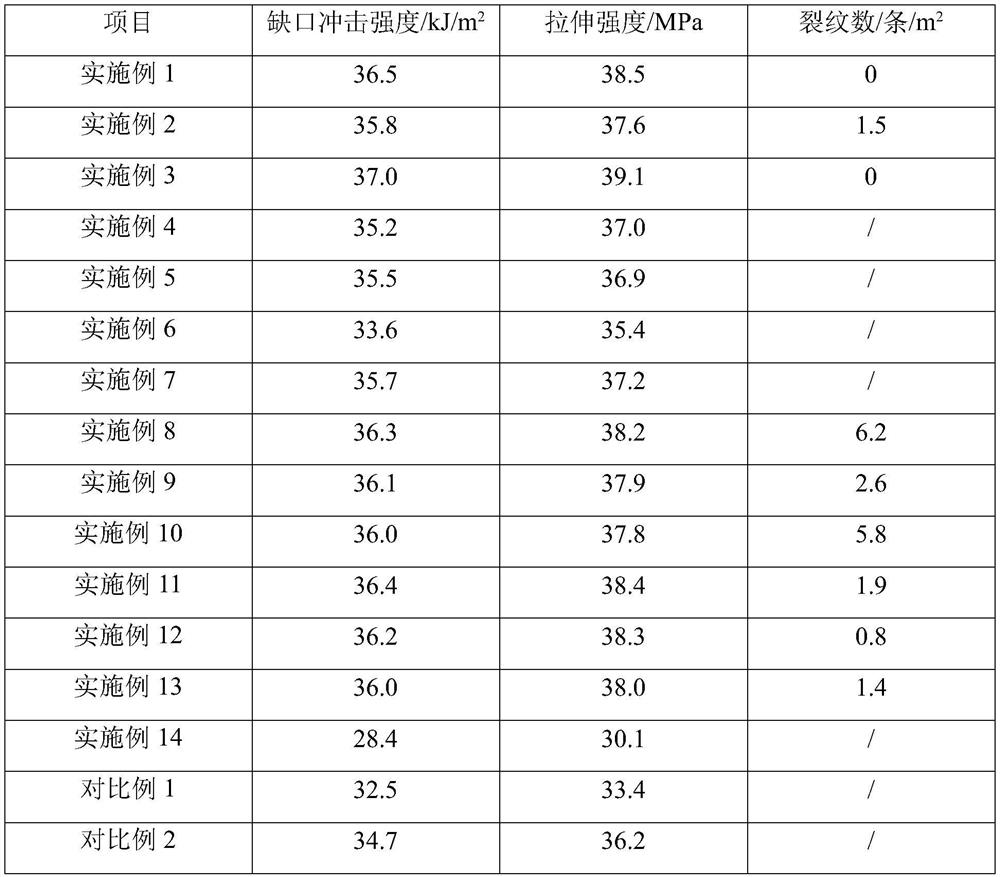

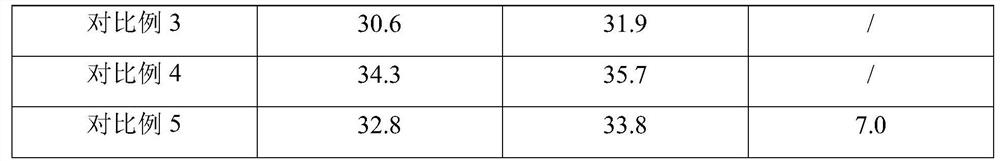

Examples

preparation example 1

[0047] Preparation Example 1: The modified silicon carbide fiber was prepared by the following method:

[0048] Weigh 1kg of silicon carbide fiber and place it in 3kg of triethylenetetramine solution, ultrasonically disperse it for 5min at 20kHz, the length of silicon carbide fiber is 1μm, and triethylenetetramine is an aqueous solution of triethylenetetramine with a mass fraction of 20%, then Modified silicon carbide fibers are prepared by drying and dispersing until they are not bonded to each other.

preparation example 2

[0049] Preparation Example 2: The modified silicon carbide fiber was prepared by the following method:

[0050] Weigh 1kg of silicon carbide fiber and place it in 2kg of triethylenetetramine solution, ultrasonically disperse it for 5min under the condition of 20kHz, the length of silicon carbide fiber is 1μm, and triethylenetetramine is an aqueous solution of triethylenetetramine with a mass fraction of 20%, then Modified silicon carbide fibers are prepared by drying and dispersing until they are not bonded to each other.

preparation example 3

[0051] Preparation Example 3: The modified silicon carbide fiber was prepared by the following method:

[0052] Weigh 1kg of silicon carbide fiber and place it in 4kg of triethylenetetramine solution, ultrasonically disperse it for 5min at 20kHz, the length of silicon carbide fiber is 1μm, and triethylenetetramine is an aqueous solution of triethylenetetramine with a mass fraction of 20%, then Modified silicon carbide fibers are prepared by drying and dispersing until they are not bonded to each other.

[0053] Preparation example of adhesion-promoting paint

[0054] The following raw materials and equipment are all commercially available.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com