Improved quick high vacuum densification soft foundation treatment method

A high-vacuum, soft-foundation technology, applied in infrastructure engineering, soil protection, construction, etc., to achieve high drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

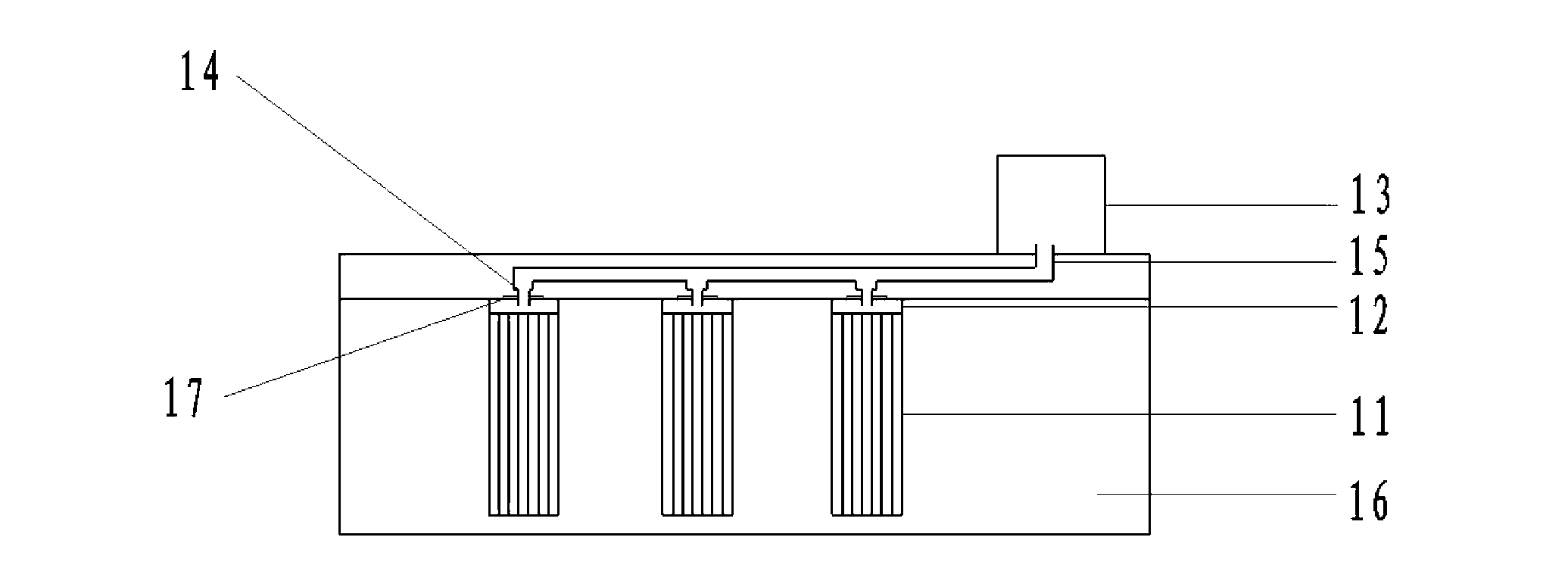

[0030] Such as figure 1 As shown, in a port yard project, the soil layer is muddy soil with a thickness of about 10-12 meters, a water content of 65%, and a permeability coefficient of 10. -4 cm / s.

[0031] Design requirements: the bearing capacity of the soft foundation 16 within 12 meters reaches 100KPa.

[0032] The specific implementation plan is as follows:

[0033] The first step is to insert several groups of plastic drainage boards 11 wrapped with geotextiles into the soft foundation 16, wherein the plastic drainage boards 11 are distributed in a rectangular shape, and the distance between the inserted plastic drainage boards 11 is 0.3 to 2 meters. The upper end of the drainage plate 11 is closed with a cover 12, and the cover 12 is provided with an interface, which is connected to one end of the conduit 14, and the other end of the conduit 14 is connected to the vacuum equipment 13 with the corresponding horizontal horizontal pipe 15, and the horizontal The horizo...

Embodiment 2

[0046] Such as figure 1 As shown, the geological condition of a seaside development zone is that the soil layer is silty soil with a thickness of about 10-15 meters, a water content of 70%, and a permeability coefficient of 1.5×10 -6 cm / s.

[0047] Design requirements: the bearing capacity of the soft foundation 16 within 15 meters reaches 120KPa.

[0048] The specific implementation plan is as follows:

[0049] The first step is to insert several groups of plastic drainage boards 11 wrapped with geotextiles into the soft foundation 16, wherein the plastic drainage boards 11 are distributed in a rectangular shape, and the distance between the inserted plastic drainage boards 11 is 2 to 4 meters. The upper end of the drainage board 11 is closed with a cover 12, and the cover 12 is provided with an interface, which is connected to one end of the conduit 14, and the other end of the conduit 14 is connected to the vacuum equipment 13 with the corresponding horizontal horizontal...

Embodiment 3

[0062] Such as figure 1 As shown, a soft foundation 16 along the river, the soil layer is silty soil, about 12-18 meters thick, with a water content of about 75% and a permeability coefficient of 10 -9 cm / s.

[0063] Design requirements: the bearing capacity of the soft foundation 16 within 18 meters reaches 140KPa.

[0064] The specific implementation plan is as follows:

[0065] In the first step, several groups of plastic drainage boards 11 wrapped with geotextiles are completely inserted into the soft foundation 16, wherein the plastic drainage boards 11 are distributed in a quincunx shape, and the distance between the inserted plastic drainage boards 11 is 3 to 5 meters. The upper end of the plastic drainage plate 11 is closed with a cover 12, and the cover 12 is provided with an interface, which is connected to one end of the conduit 14, and the other end of the conduit 14 is connected to the corresponding horizontal horizontal pipe 15 to the vacuuming device 13, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com