Concrete viscosity regulator suitable for compatible use with polycarboxylic acid water reducer and preparation method thereof

A technology of viscosity modifier and water reducer, which is applied in the field of concrete viscosity modifier and its preparation, which can solve the problems of high viscosity of concrete, difficulty in construction, segregation and bleeding of concrete, etc., so as to increase mechanical properties and durability, and reduce slump Temperature and gas content, reducing the effect of loss over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

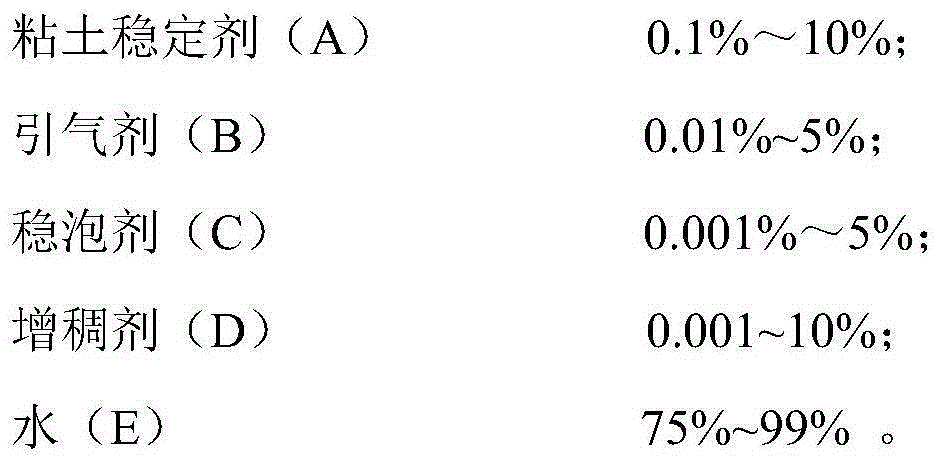

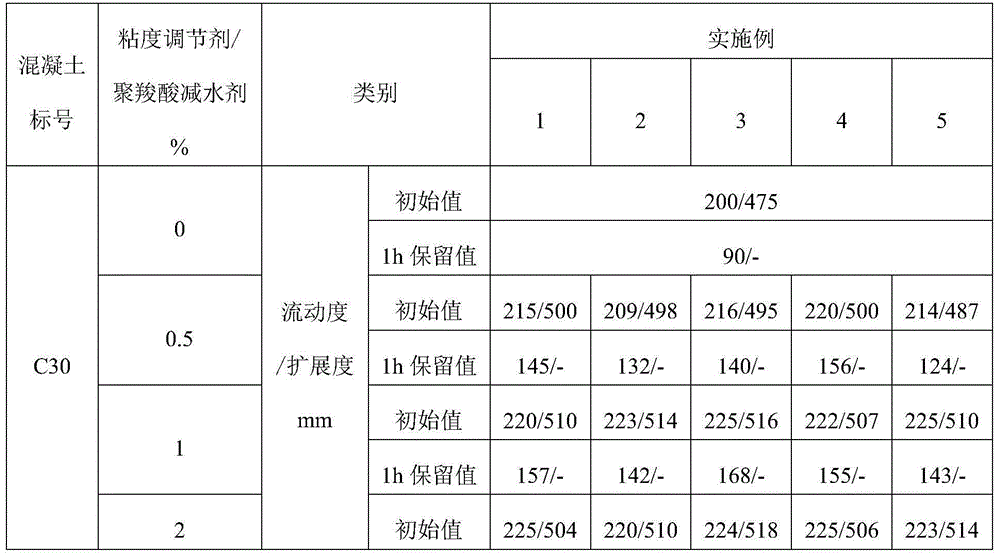

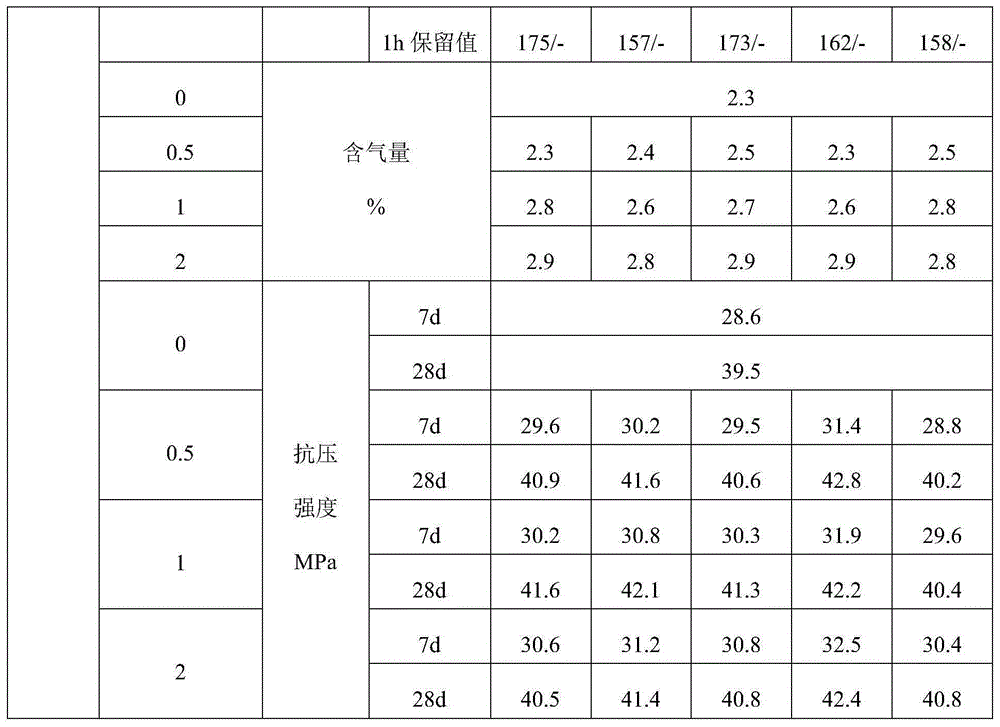

Embodiment 1

[0022] The concrete viscosity modifier suitable for use with polycarboxylate water reducer in this embodiment, the weight components are: dodecyltrimethylammonium chloride: 3.50%; fatty alcohol polyoxyethylene ether sodium sulfate: 0.05%; N,N'-sodium dilauroyl ethylenediamine acetate: 0.02%; Cellulose ether: 1.25%; Water: 95.18%, the above-mentioned components are accurately weighed by weight percentage, according to the results of Example 6 Said process makes the present invention.

Embodiment 2

[0024] The concrete viscosity modifier suitable for use with polycarboxylate water reducer in this embodiment, the weight components are: dimethyl diallyl ammonium chloride polymer: 2.67%; triterpene saponin: 0.50%; Sodium methyl cellulose: 0.30%; Wenlun rubber: 0.06%; water: 96.47%, the above-mentioned components are accurately weighed by weight percentage, and the present invention is obtained by the described process in Example 6.

Embodiment 3

[0026] The concrete viscosity regulator suitable for use in combination with polycarboxylate superplasticizers in this embodiment has the following components by weight: cetyltrimethylammonium bromide: 3.20%; sodium lauryl sulfate: 2.75%; Polyvinyl alcohol: 0.25%; polyacrylamide: 0.50%; water: 93.30%, the above-mentioned components are accurately weighed by weight percentage, and the present invention is obtained according to the process described in Example 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com