Preparation method of high-strength type foaming and cushioning packaging material

A cushioning packaging and high-strength technology, applied in the field of packaging material preparation, can solve problems such as poor mechanical properties, achieve the effect of modifying mechanical properties, increasing pores, and improving the gel network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

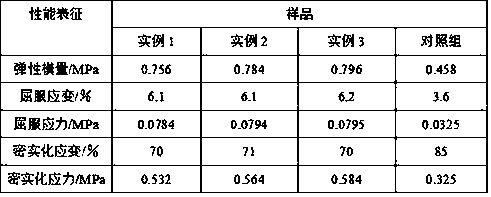

example 1

[0018] Take the bamboo pulp board and air-flow pulverization, pass 200 mesh sieves to get the bamboo pulp board powder, press the mass ratio 1:5, stir and mix the bamboo pulp board powder and deionized water and place it in a vertical beater, beating until the degree of knocking is 45 ° SR, vacuum freeze-drying and collect dry matter, ball milling and crossing 200 mesh sieves to get bamboo pulp fiber; by weight parts, weigh 5 parts of bamboo pulp fiber, 55 parts of deionized water, 2 parts of starch and 1 part of magnesium chloride is placed in a beaker, stirred and mixed, and placed under 200W for 10 minutes of ultrasonic vibration treatment, the dispersion is collected and sealed for fermentation, after 7 days of sealed fermentation at 35°C, the fermented product is obtained and filtered, and the filter cake and filtrate are collected respectively. After the filter cake was rinsed with deionized water for 3 times, and vacuum freeze-dried for 6 hours, the modified fiber was ob...

example 2

[0020] Take the bamboo pulp board and air-flow pulverization, pass 200 mesh sieves to get the bamboo pulp board powder, press the mass ratio 1:5, stir and mix the bamboo pulp board powder and deionized water and place it in a vertical beater, beating until the degree of knocking is 45 ° SR, vacuum freeze-drying and collect dry matter, ball milling and crossing 200 mesh sieves to get bamboo pulp fiber; by weight parts, weigh 7 parts of bamboo pulp fiber, 57 parts of deionized water, 3 parts of starch and 2 parts of magnesium chloride were placed in a beaker, stirred and mixed, and placed under 250W for 12 minutes of ultrasonic vibration, the dispersion was collected and fermented in a sealed manner. After 8 days of sealed fermentation at 37°C, the fermented product was obtained and filtered, and the filter cake and filtrate were collected respectively. After the filter cake was washed with deionized water for 4 times, and vacuum freeze-dried for 7 hours, the modified fiber was o...

example 3

[0022] Take the bamboo pulp board and air-flow pulverization, pass 200 mesh sieves to get the bamboo pulp board powder, press the mass ratio 1:5, stir and mix the bamboo pulp board powder and deionized water and place it in a vertical beater, beating until the degree of knocking is 45 ° SR, vacuum freeze-drying and collect dry matter, ball milling and crossing 200 mesh sieves to get bamboo pulp fiber; by weight parts, weigh 10 parts of bamboo pulp fiber, 60 parts of deionized water, 3 parts of starch and 2 parts of magnesium chloride were placed in a beaker, stirred and mixed, and placed under 300W for 15 minutes of ultrasonic vibration treatment, the dispersion was collected and sealed for fermentation, after 10 days of sealed fermentation at 40°C, the fermented product was obtained and filtered, and the filter cake and filtrate were collected respectively. After the filter cake was rinsed with deionized water for 5 times, and vacuum freeze-dried for 8 hours, the modified fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com