Nano multi-layer composite solid lubricating film layer with long service life under space irradiation and preparation thereof

A nano-multilayer, solid-lubrication technology, applied in coating, vacuum evaporation coating, metal material coating process, etc., can solve the problems of not having resistance to space atomic oxygen erosion, electron proton irradiation, application of immovable parts, etc. Achieve excellent anti-space irradiation performance, ensure long-term reliable operation, and enhance the effect of anti-space irradiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

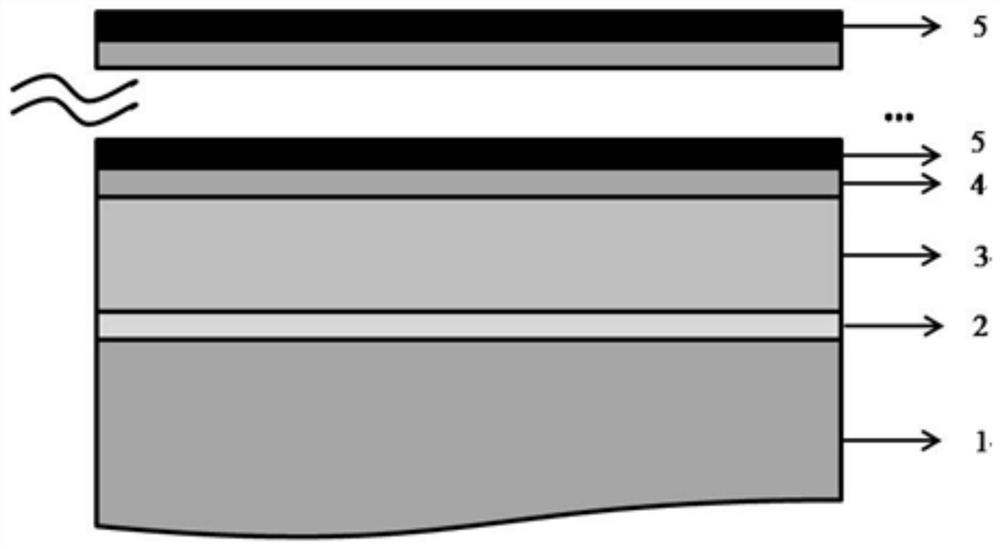

[0043] This embodiment provides a long-life nanometer multi-layer composite solid lubricating film layer under space irradiation environment. MoS 2 Ti is alternately repeated 10 times, and the number of prepared functional layers is 20 layers. The content of Ag and Ni elements in the AgTiNi layer is 9:1, and Ti elements account for 10% of the total. MoS 2 MoS in Ti 2 The composition ratio with Ti is 9:1, and the total thickness of the film layer is 2.5 μm thick nano-multilayer composite solid lubricating film layer.

[0044] The specific preparation process of the long-life nano-multilayer composite solid lubricating film layer under the above-mentioned space irradiation environment is carried out according to the following steps:

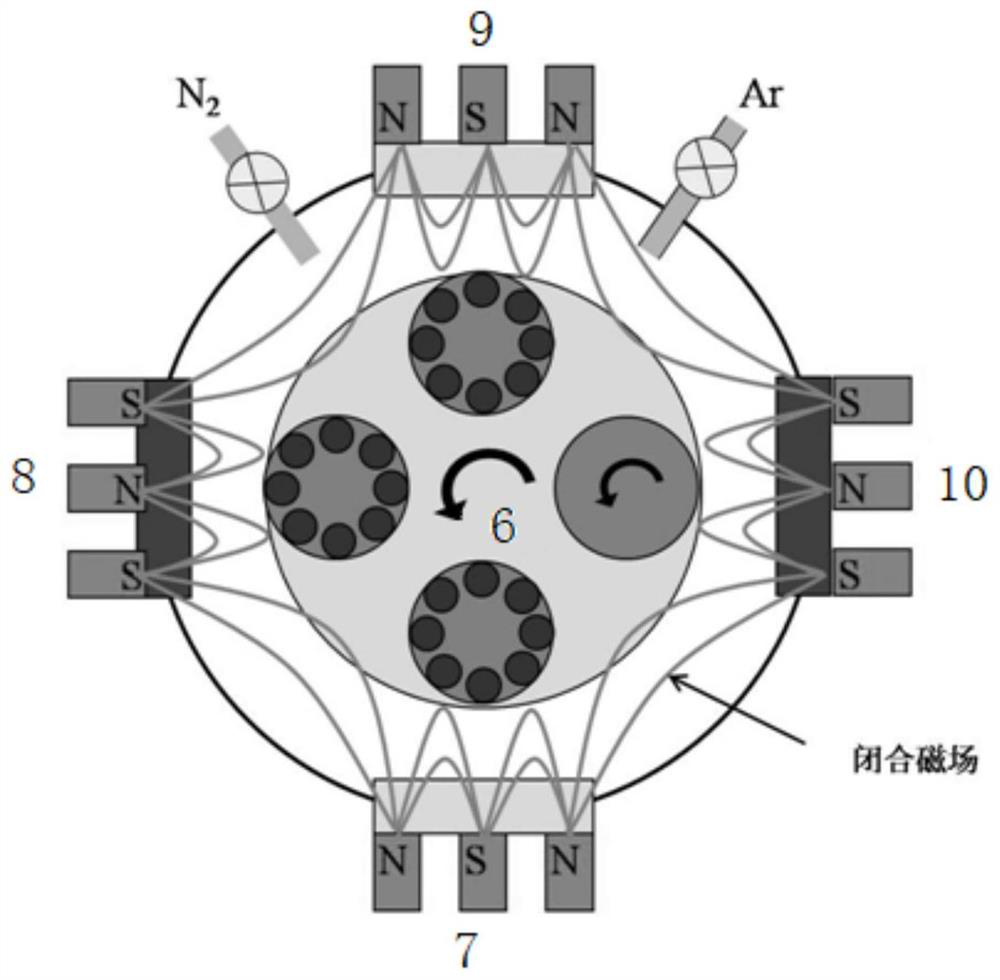

[0045] 1) Sputter cleaning: attached figure 2 The coating layer equipment shown (the equipment includes sample turntable, air intake system, Ti target, two MoS 2 target and AgNi target), the 7 position is the Ti target, the 8 and 10 positions a...

Embodiment 2

[0053] The present invention is a long-life nanometer multi-layer composite solid lubricating film layer under space irradiation environment, the substrate is TC4, a Ti binding layer with a thickness of 10nm, a TiN bearing layer with a thickness of 1μm, an AgTiNi functional layer with a thickness of 80nm and MoS with a thickness of 120nm 2 Ti is alternately repeated 5 times, and the number of functional layers prepared is 10. The content of Ag and Ni elements in the AgTiNi layer is 9:1, and Ti elements account for 10% of the total. MoS 2 The proportion of Ti in Ti is 5%, and the total thickness of the film layer is about 2 μm thick nano-multilayer composite solid lubricating film layer.

[0054] The specific preparation process of the long-life nano-multilayer composite solid lubricating film layer under the above-mentioned space irradiation environment is carried out according to the following steps:

[0055] 1) Sputter cleaning: attached figure 2 In the coating layer equipm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com