Electronic product aluminum shell cold forging (cold heading) method and product thereof

A cold forging technology for electronic products and aluminum shells, which is applied in the field of cold forging aluminum shells, can solve the problems of cumbersome aluminum shell manufacturing process, high production cost, and low production efficiency, and achieve shortened production cycle, low cost, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

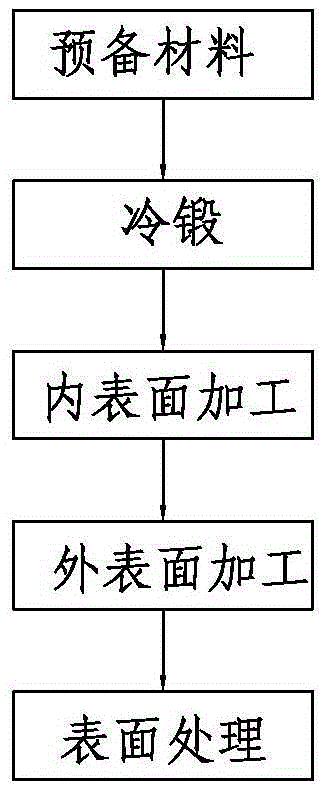

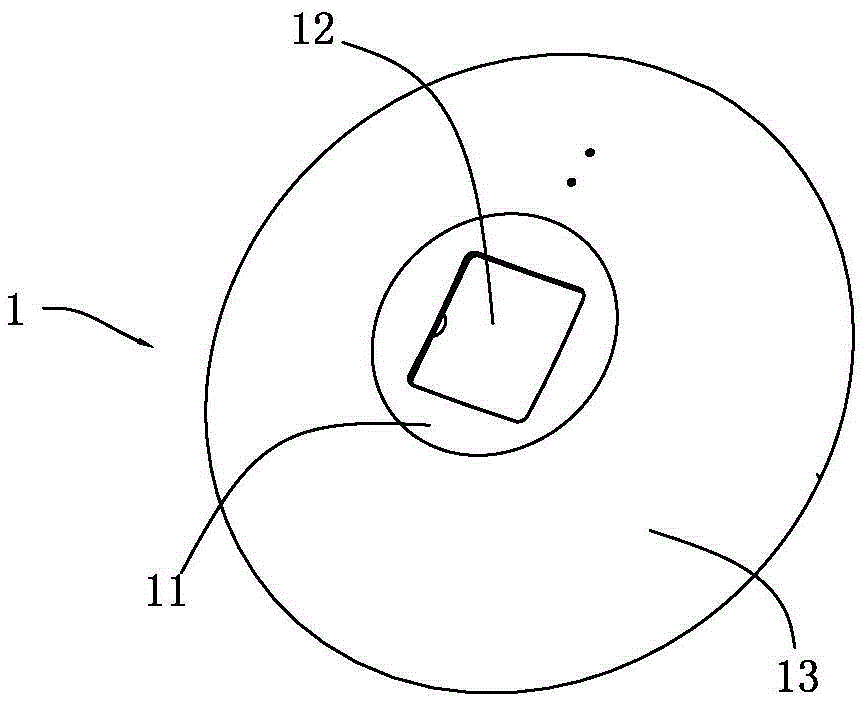

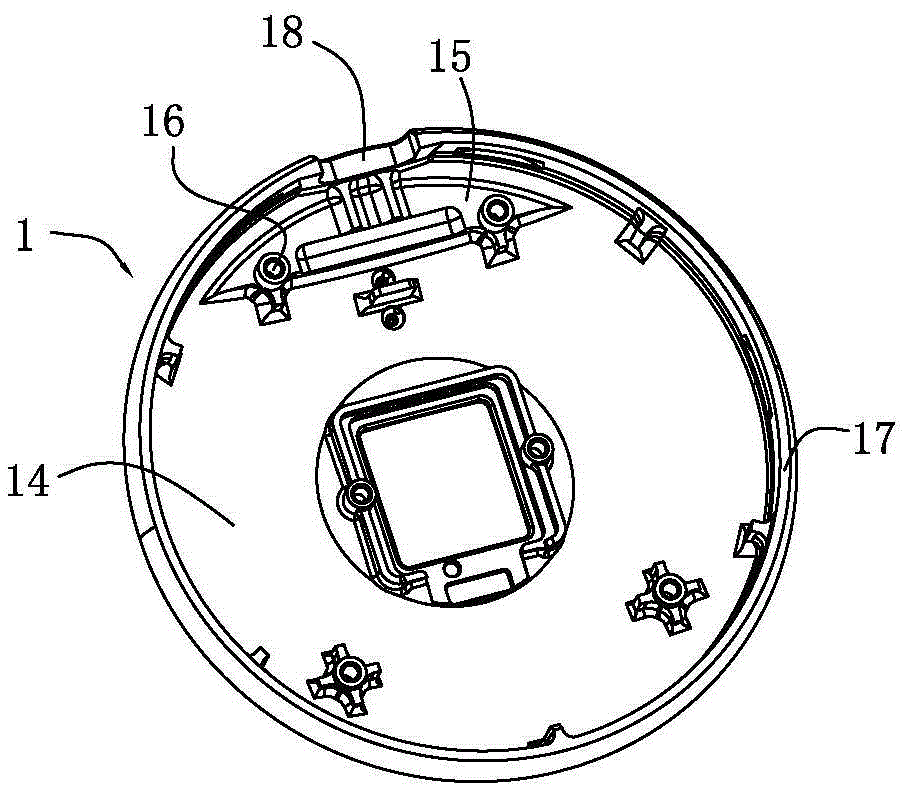

[0030] Example: see figure 1 , figure 2 and image 3 , an embodiment of the present invention provides a method for cold forging (cold heading) of an aluminum shell of an electronic product, which includes the following steps:

[0031] (1) Preparing materials: preparing an aluminum plate body; specifically, the step (1) specifically includes the following steps: (1.1) purchasing an aluminum plate body; (1.2) cutting the aluminum plate body according to the desired shape. Of course, it is also possible to directly purchase an aluminum plate body of a corresponding shape without cutting the process. In this embodiment, take the cold forged fingerprint product cover as an example, see figure 2 and image 3 , is the structural diagram of the product. Preferably, the thickness of the aluminum plate body is 5mm, preferably 6030 aluminum, and there is no aging treatment.

[0032] (2) Cold forging: place the aluminum plate body on the cold forging die, and operate the hydrauli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com