Preparation method of sealed high-energy-storage lead-acid storage battery with quick charging and discharging function

A lead-acid battery, charging and discharging technology, applied in the direction of lead-acid battery, lead-acid battery electrodes, lead-acid battery construction, etc., can solve the problems of slow charging and discharging speed, reduced thickness, low battery energy density, etc., to prevent coating Effects of breaking, reducing thickness, increasing cycle times and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of a fast charge-discharge sealed high-energy storage lead-acid battery, the specific steps are as follows:

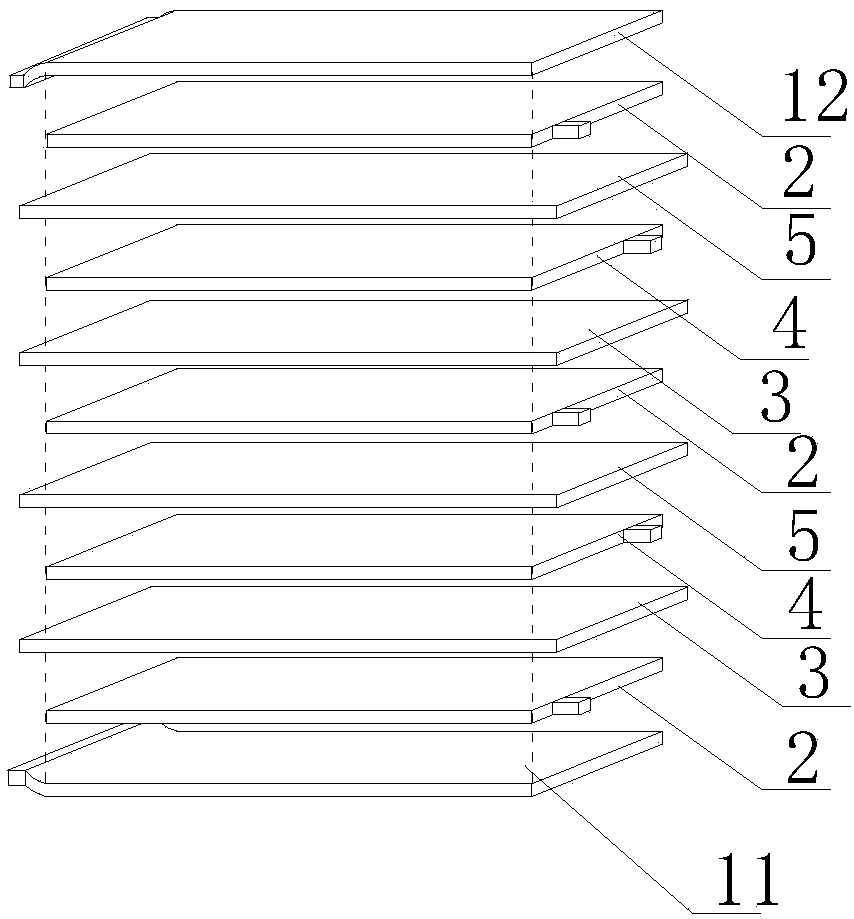

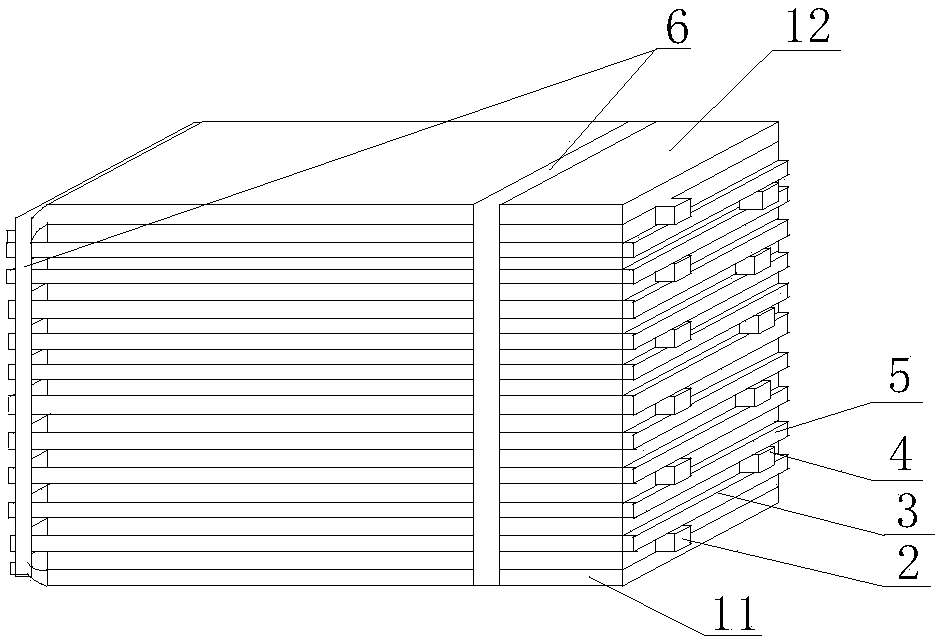

[0037] 1) Spraying fluid lead paste: first spray the negative electrode flow paste on the splint surface of A splint 11, the lower surface of the negative electrode plate 2 on the plate unit is pressed on the negative electrode flow paste sprayed on the splint surface of A splint 11, on the negative electrode plate 2 Spray the negative electrode flow paste on the upper surface, press the lower surface of the first oxygen-enriched separator 3 on the negative electrode flow paste on the upper surface of the negative plate 2, spray the positive electrode flow paste on the upper surface of the first oxygen-enriched separator 3, and place the positive electrode plate 4 times The surface is pressed on the positive electrode flow paste on the upper surface of the first oxygen-enriched separator 3, the positive electrode flow paste is sprayed on the ...

Embodiment 1

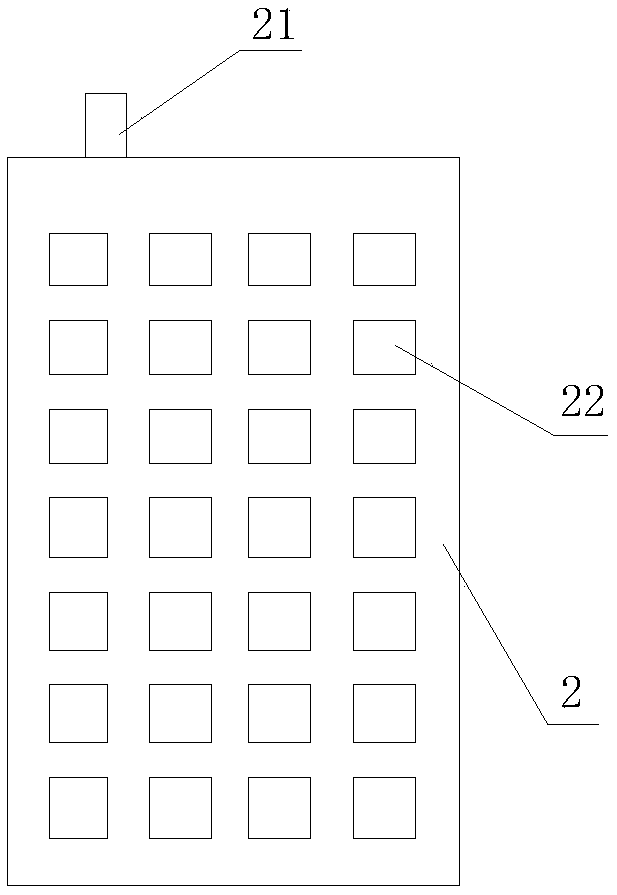

[0042] The positive plate is made of small holes evenly opened on the corrosion-resistant alloy sheet, the thickness of the positive plate is 0.1mm, and the area of the small holes of the positive plate is 5mm 2 , the ratio of the total area of the openings of the positive plate to the total area of the positive plate is 1:3; the negative plate is made of small holes on a pure lead sheet, its thickness is 0.1mm, and the area of the small holes of the negative plate is 2mm 2 , the ratio of the sum of the opening areas of the negative plate to the total area of the negative plate is 1:3, and electrothermal extrusion is carried out to form small holes. The corresponding side of the lug gradually becomes thicker to the other side. The separator is composed of AGM separators with fine wire diameter on both sides and AGM separator with thick wire diameter in the middle. The anti-expansion sleeve is made of high-strength metal with low expansion rate. The oxygen concentrati...

Embodiment 2

[0044] The positive plate is made of evenly opening small holes on a pure lead sheet, the thickness of the positive plate is 1mm, and the area of the small holes of the positive plate is 20mm 2 , the ratio of the sum of the opening areas of the positive plate to the total area of the positive plate is 1:4; the negative plate is made of copper wire mesh, its thickness is 0.5mm, and the small hole area of the negative plate is 7mm 2 , the ratio of the total area of the openings of the negative plate to the total area of the negative plate is 1:5, electrothermal extrusion is carried out to form small holes, the thickness of the oxygen-enriched separator is 0.5mm, and the thickness of the oxygen-enriched separator adopts a uniform thickness as a whole Setting, the partition is made of AGM+PE two types of partitions, the anti-expansion sleeve is made of polymer materials, and the oxygen concentration in the partition is 95%. The surface of the positive plate and the negat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com