Method for dissipating charges on end face of cover tape

A technology of charge dissipation and cover tape, applied in the direction of flexible coverings, packaging, layered products, etc., can solve the effect of affecting the heat seal stability of the heat seal layer and the carrier tape, bad, static electricity caused by tearing the cover tape, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

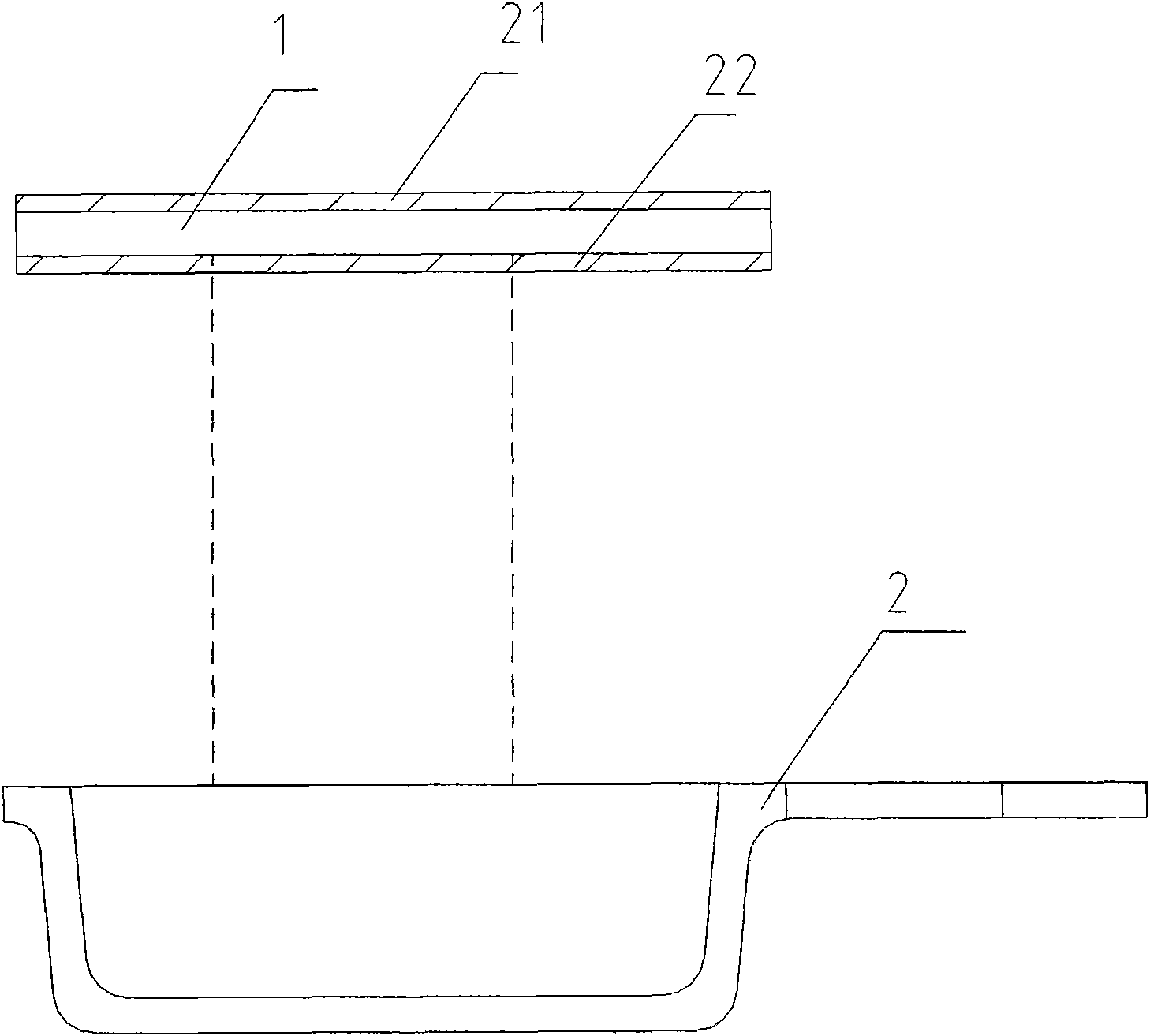

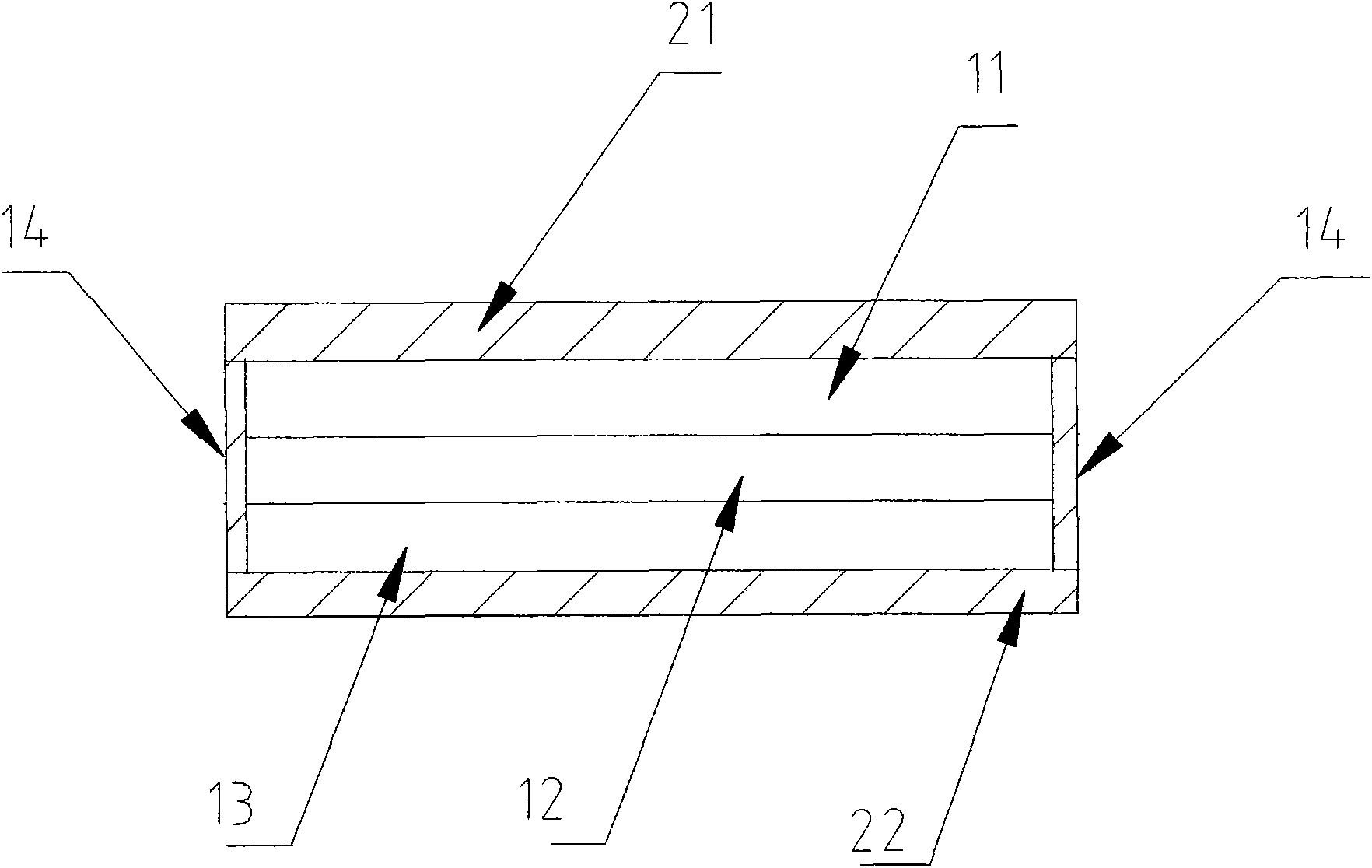

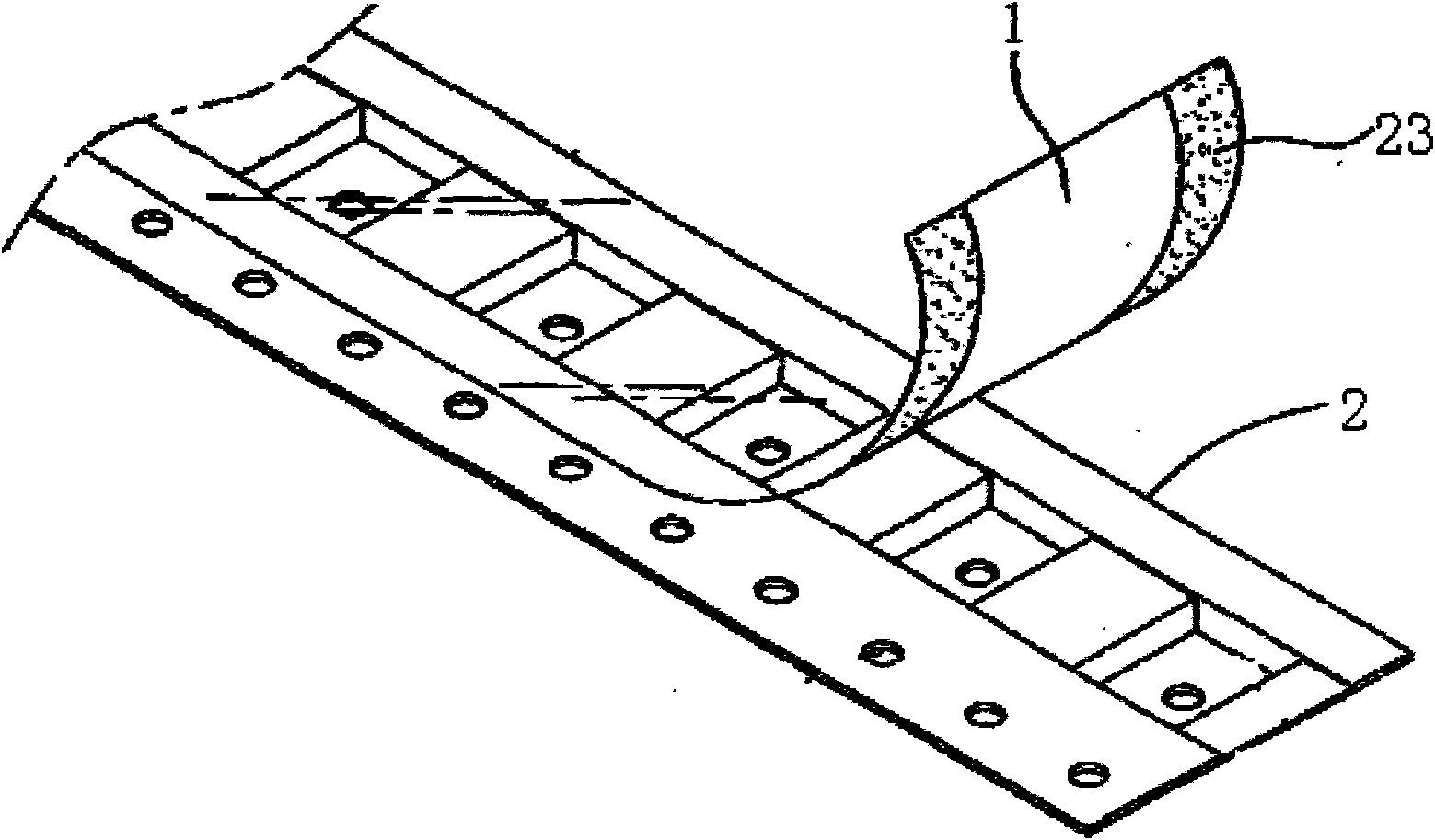

[0019] like figure 1 , 2 As shown, the method for dissipating charge on the end surface of the cover tape is used in the sealing process of the cover tape 1 and the carrier tape 2, wherein the cover tape 1 includes an upper surface layer 11, an intermediate layer 12 and a heat-sealing layer 13 from top to bottom. , the heat-sealing layer 13 can be bonded with the carrier tape 2 . Carrying out bonding, at first should be on the upper surface of upper surface layer 11, the both sides end faces of loam cake 1 and the lower surface of heat seal layer 13 are coated with antistatic agent, form antistatic layer 21,14,22 respectively, as figure 2 As shown, the antistatic layer 21, 14, 22 has formed an integral antistatic layer, and when the upper cover is pulled away, the antistatic effect of the upper surface of the upper surface layer 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com