Compound gridding rib layer product with surface protecting paper and preparation method thereof

A technology of grid rib and cover paper, applied in the field of building materials, can solve the problems of increased manufacturing cost, unreasonable layout of glass fiber rib structure, low level of mechanical strength, fire stability and fire resistance limit performance, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

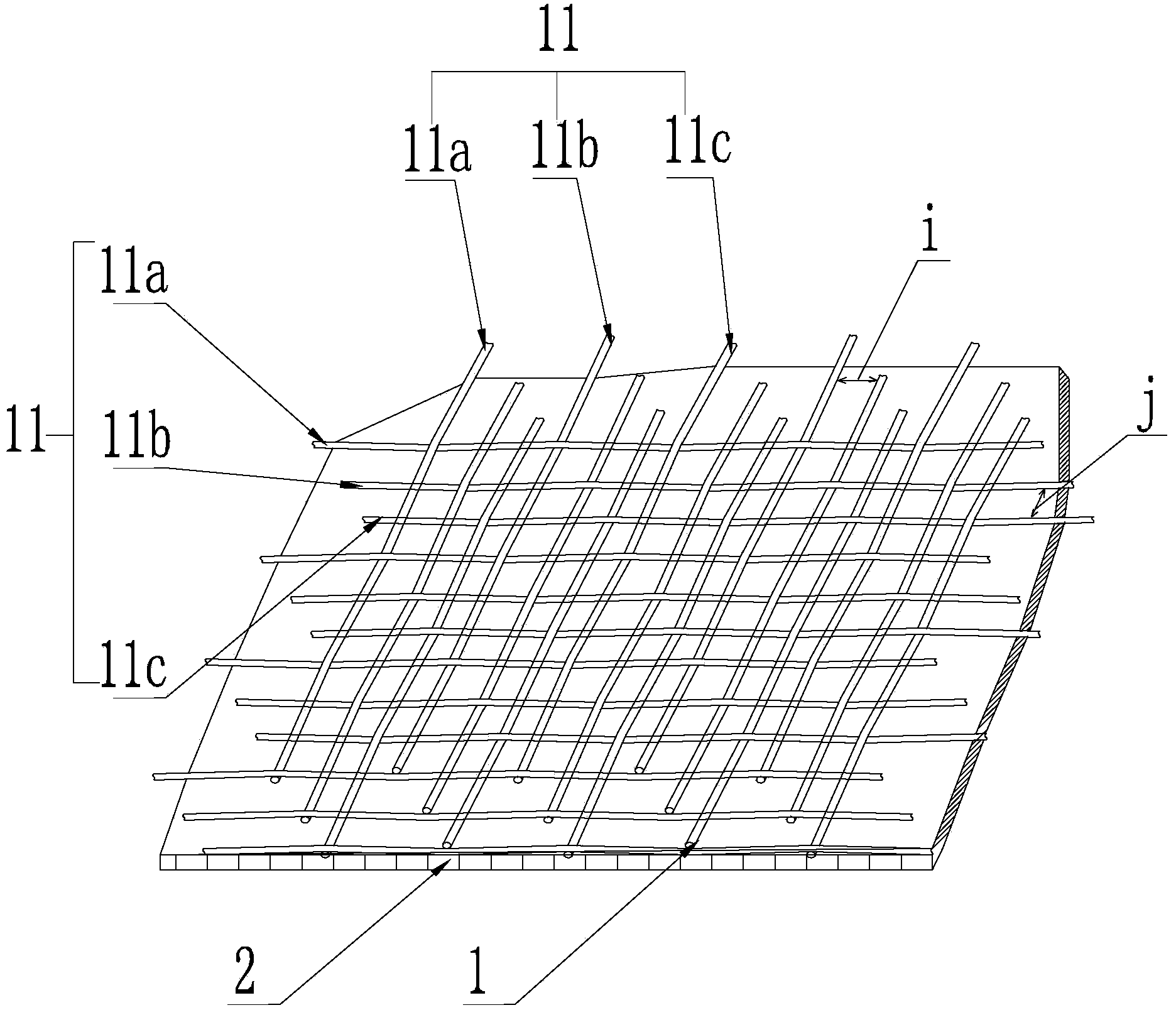

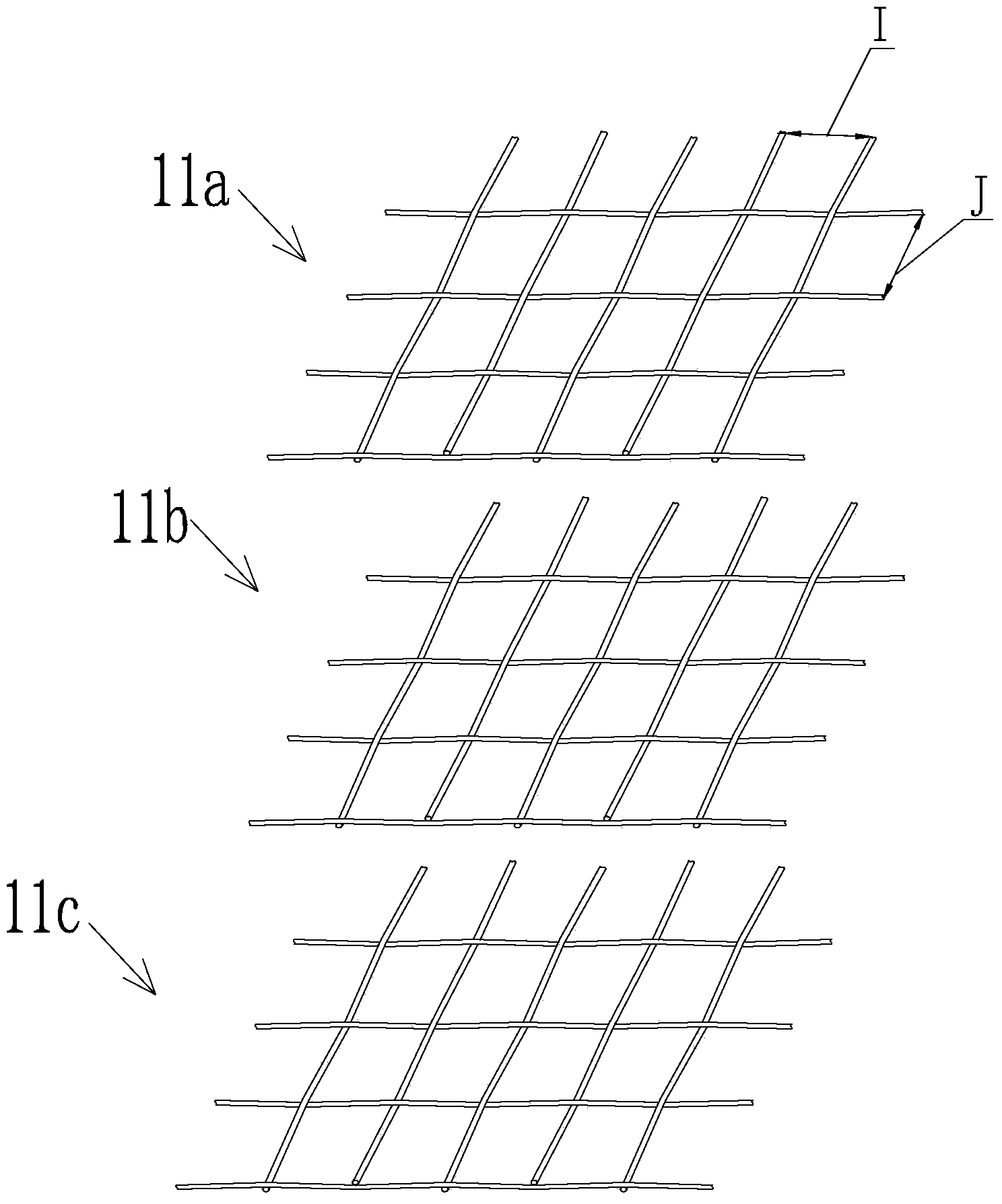

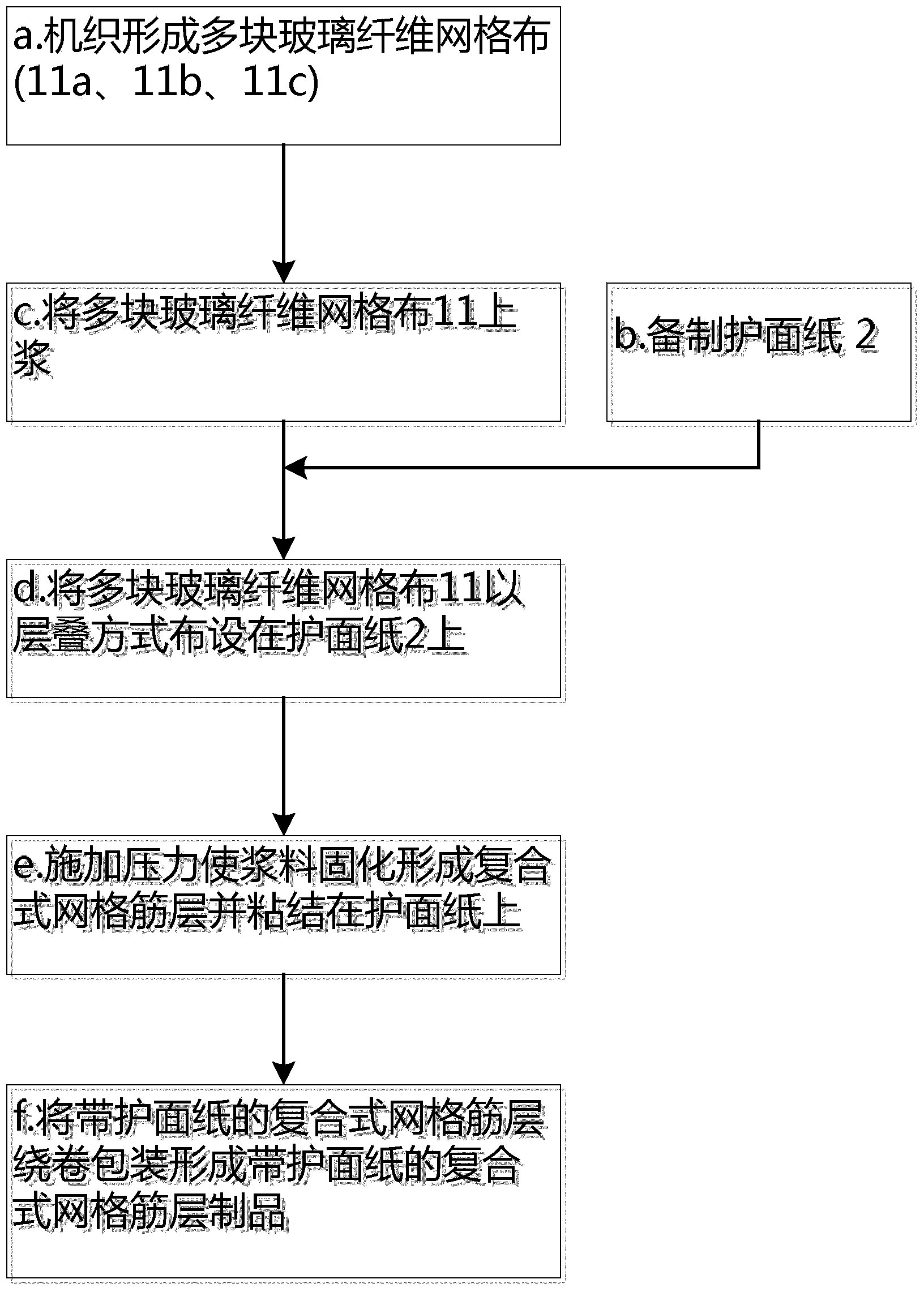

[0027] Combine below Figure 1 to Figure 3 The given examples further illustrate the specific implementation and preparation method of the composite lattice bar laminated product with protective paper of the present invention. Specific embodiments of the present invention are not limited to the description of the following examples.

[0028] see Figure 1 to Figure 3 , the composite mesh tendon layer product with protective paper of the present invention, it comprises composite mesh tendon layer 1 and facing paper 2, and composite mesh tendon layer 1 comprises 3 layers of glass fiber mesh cloth 11,3 The layers of fiberglass scrim 11 are indicated by 11a, 11b and 11c, respectively. Fiberglass mesh cloth 11 is not limited to three layers, it can be multi-layered, however, too many layers will increase the processing cost, and too few layers can not effectively increase the reinforcement density, thus, the preferred number of layers 2 to 10 layers, that is, the number of layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com