Preparation method of yttrium aluminium garnet doped transparent laser ceramics

A technology of yttrium aluminum garnet and transparent ceramics, which is applied in the field of preparation of transparent laser ceramics doped with yttrium aluminum garnet, can solve the problems of poor sintering activity of powder, high sintering temperature of transparent ceramics, and high preparation cost, and achieve high sintering activity and dispersibility, overcome the dependence on raw materials, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

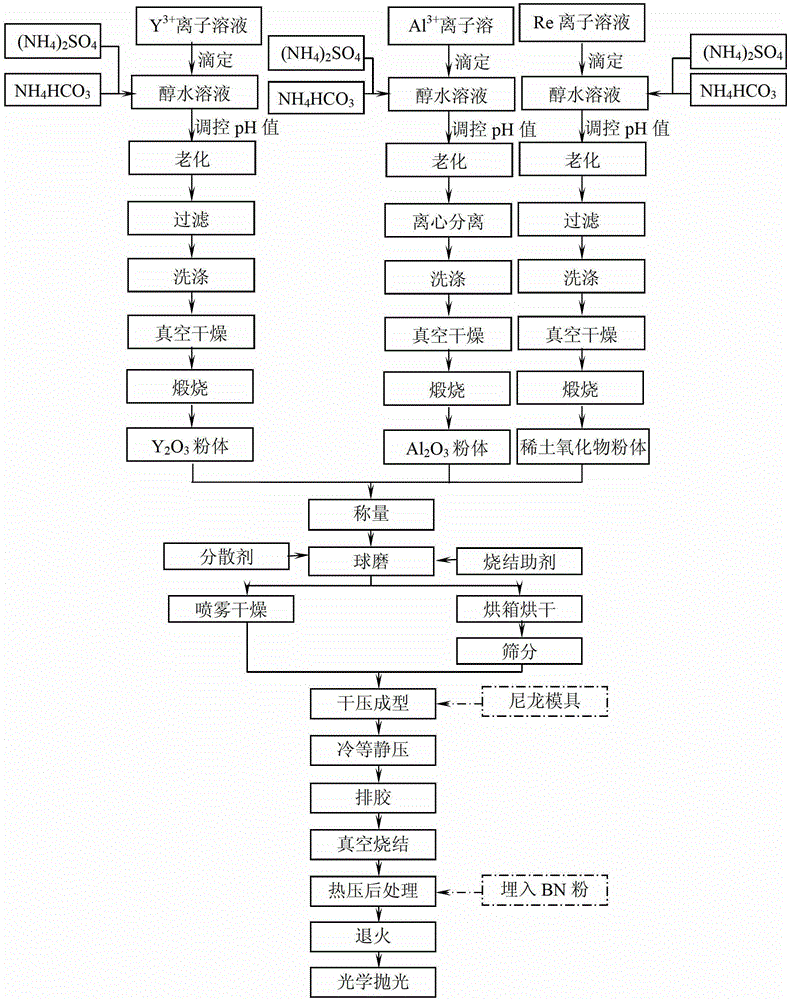

Method used

Image

Examples

Embodiment 1

[0072] Weigh 78.62g of Y (NO 3 ) 3 ·6H 2 O, dissolved in deionized water to form 0.1mol L -1 Y(NO 3 ) 3 solution. Take 118.58g of ammonium bicarbonate with a purity better than 99.9%, dissolve it in a mixed solution composed of deionized water and absolute ethanol at a volume ratio of 1:1, and form a concentration of 0.2mol L -1 Ammonium bicarbonate alcoholic aqueous solution, add (NH 4 ) 2 SO 4 (ammonium sulfate and Y(NO 3 ) 3 ·6H 2 The molar ratio of O is 1:2) as a dispersant to obtain NH 4 HCO 3 mixture. After stirring evenly, Y(NO 3 ) 3 The solution was added dropwise to NH at a rate of 5ml / min 4 HCO 3 in the mixed solution. Meanwhile, the ammonium bicarbonate mixed solution was constantly stirred with a stirrer, and the pH value of the mixed solution was monitored with an acidity meter, and the pH value of the solution was adjusted between 7.0 and 7.5 with ammonia water and nitric acid. After the titration, the solution was aged for 24 hours. The preci...

Embodiment 2

[0079] Weigh 60.68g of YCl with a purity of 4N with a balance 3 ·6H 2 O, dissolved in deionized water to form 0.1mol L -1 YCl 3 solution. Take 118.58g of ammonium bicarbonate with a purity better than 99%, and dissolve it in a mixed solution composed of deionized water and absolute ethanol at a volume ratio of 2:1 to form a concentration of 2mol L -1 Ammonium bicarbonate alcoholic aqueous solution, add (NH 4 ) 2 SO 4 ((NH 4 ) 2 SO 4 with YCl 3 ·6H 2 The molar ratio of O is 2:1) as a dispersant to obtain a mixed solution of ammonium bicarbonate. After stirring well, the YCl 3 The solution was added dropwise to NH at a rate of 0.5ml / min 4 HCO 3in the mixed solution. Meanwhile, the mixed solution was continuously stirred with a stirrer, and the pH value of the mixed solution was monitored with an acidity meter, and the pH value of the solution was adjusted between 7.5 and 8.0 with ammonia water and nitric acid. After the titration, the solution was aged for 48 hou...

Embodiment 3

[0087] Use a balance to weigh 22.58g of Y with a purity of 5N 2 o 3 Powder, dissolved in CMOS Ⅱ grade concentrated nitric acid, and prepared with deionized water to make 0.5mol L -1 Y(NO 3 ) 3 solution. Take 158.1g of ammonium bicarbonate with a purity better than 99.9%, dissolve it in a mixed solution composed of deionized water and absolute ethanol at a volume ratio of 1:1, and form a concentration of 0.5mol L -1 Ammonium bicarbonate alcoholic aqueous solution, add appropriate amount (NH 4 ) 2 SO 4 As a dispersant ((NH 4 ) 2 SO 4 with Y 3+ ions in a molar ratio of 1:1), resulting in NH 4 HCO 3 Mix alcohol water solution. After stirring evenly, Y(NO 3 ) 3 The solution was added dropwise to NH at a rate of 10ml / min 4 HCO 3in the mixed solution. Meanwhile, the mixed solution was continuously stirred with a stirrer, and the pH value of the mixed solution was monitored with an acidity meter, and the pH value of the mixed solution was adjusted between 9.5 and 10....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com