Preparation method of nano-tungsten powder

A nano-tungsten powder and powder technology, applied in the preparation of nano-tungsten metal powder, based on the nitride conversion method to prepare nano-scale ultra-fine tungsten powder, can solve the problem of reducing the melting point and high-temperature mechanical properties of tungsten products, and cannot prepare large-scale products , not suitable for industrial production and other problems, to achieve the effect of cheap raw materials, good sintering activity, and small particle size of powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 10mmol of ammonium metatungstate and 50mmol of citric acid, dissolve them in 100ml of deionized water to obtain a clear mixed solution; perform complexation reaction in a water bath at 70°C for 5 hours; filter and dry at 120°C for 12 hours to obtain a tungsten oxide precursor body; calcined at 650°C for 3 hours in an air atmosphere to obtain WO 3 Powder.

[0031] will get WO 3 The powder is placed in a tube furnace, nitrogenated with ammonia gas, the flow rate of ammonia gas is controlled at 3L / min, the temperature is 700°C, the heating rate is 2°C / min, and the temperature is kept for 2 hours to obtain W 2 N powder.

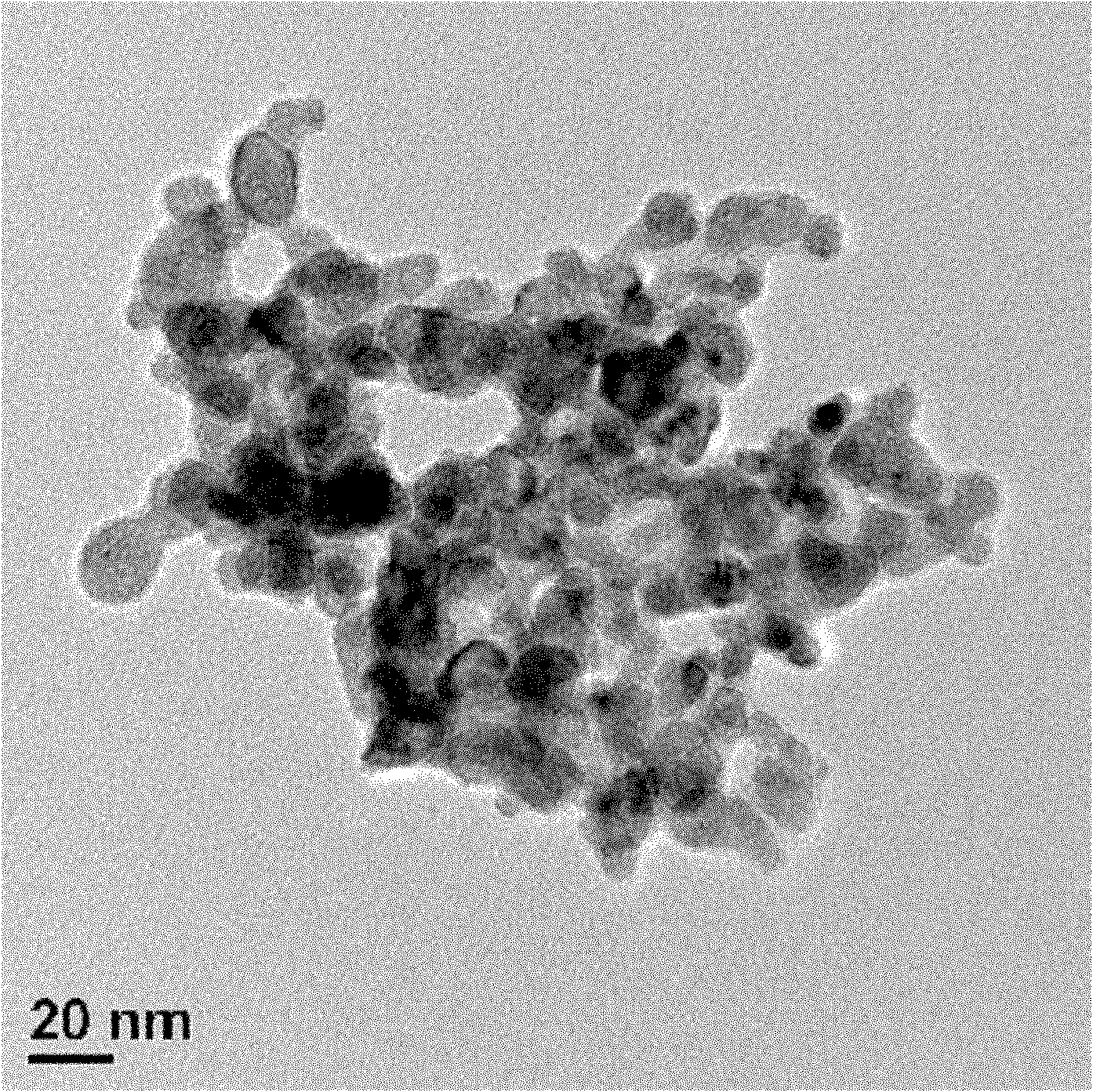

[0032] will get W 2 Place the N powder in a graphite crucible, heat it to 900°C in a carbon tube furnace under the condition that the air pressure is lower than 200Pa and keep it warm for 1 hour to obtain nano-tungsten powder with an average particle size of 20nm.

Embodiment 2

[0034] The only difference between this embodiment and embodiment 1 is: the obtained W 2 The N powder is directly placed in a tube furnace, and then reduced by passing hydrogen gas. The flow rate of hydrogen gas is 150ml / min, the heat treatment temperature is 850°C, and the time is 2 hours, and the nano-tungsten powder is obtained.

[0035] The rest of the content is exactly the same as described in Example 1.

[0036] It is known through detection and analysis that the average particle size of the nano-tungsten powder prepared in this embodiment is 40nm.

Embodiment 3

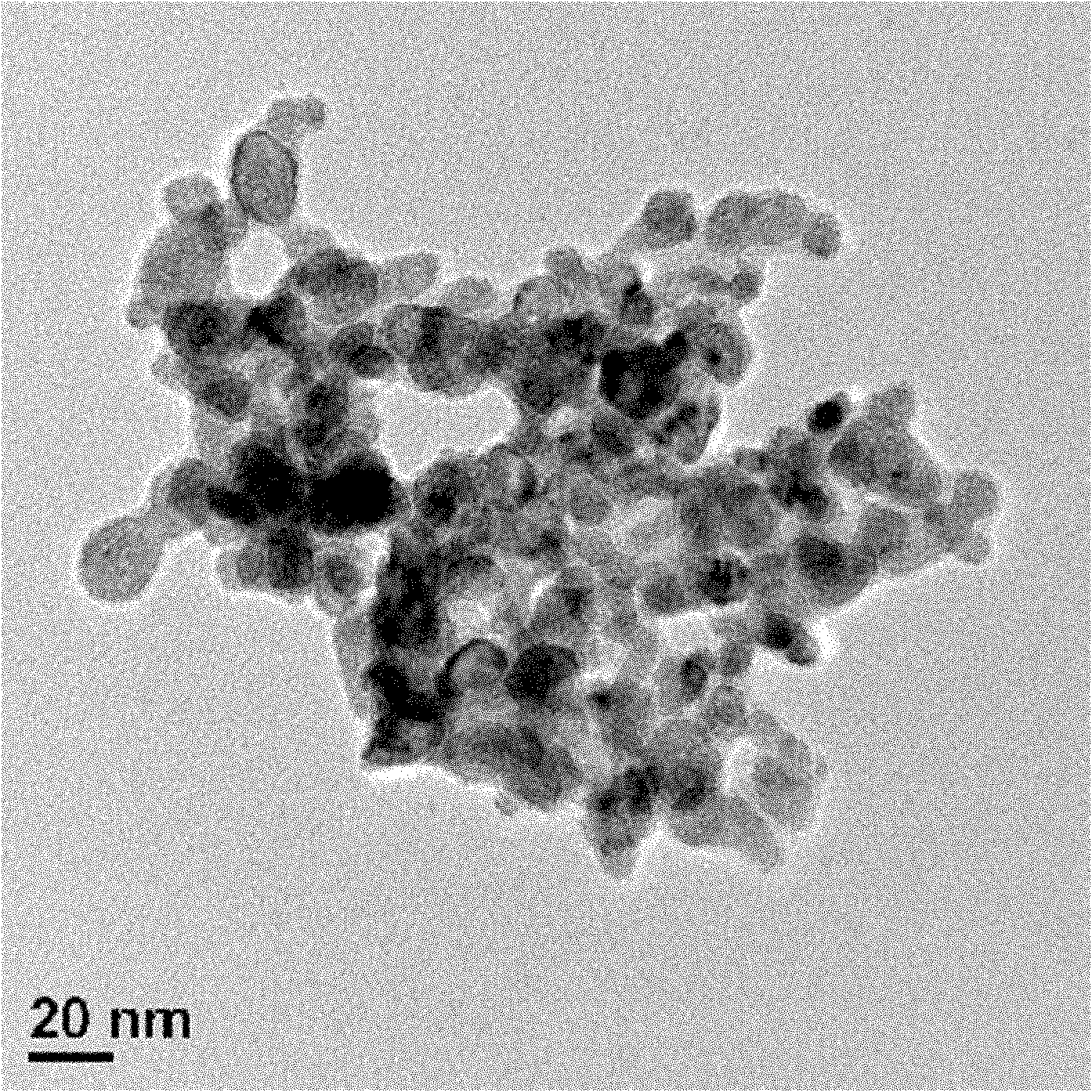

[0038] The only difference between this embodiment and embodiment 1 is: the obtained W 2 N powder is placed in a graphite crucible, and nitrogen gas is introduced into a carbon tube furnace, and the reactant is heated to 900°C and kept for 3 hours to obtain nano-tungsten powder.

[0039] The rest of the content is exactly the same as described in Example 1.

[0040] It is known through detection and analysis that the average particle size of the nano-tungsten powder prepared in this embodiment is 30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com