Nano ceramic cutter and preparation method thereof

A technology of nano-ceramics and knives, which is applied in the field of nano-ceramic knives and its preparation. It can solve the problems of deformation, affecting the toughness and strength of knives, and uneven dispersion of components, so as to achieve high sintering activity, enhanced thermal shock resistance, and component dispersion. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

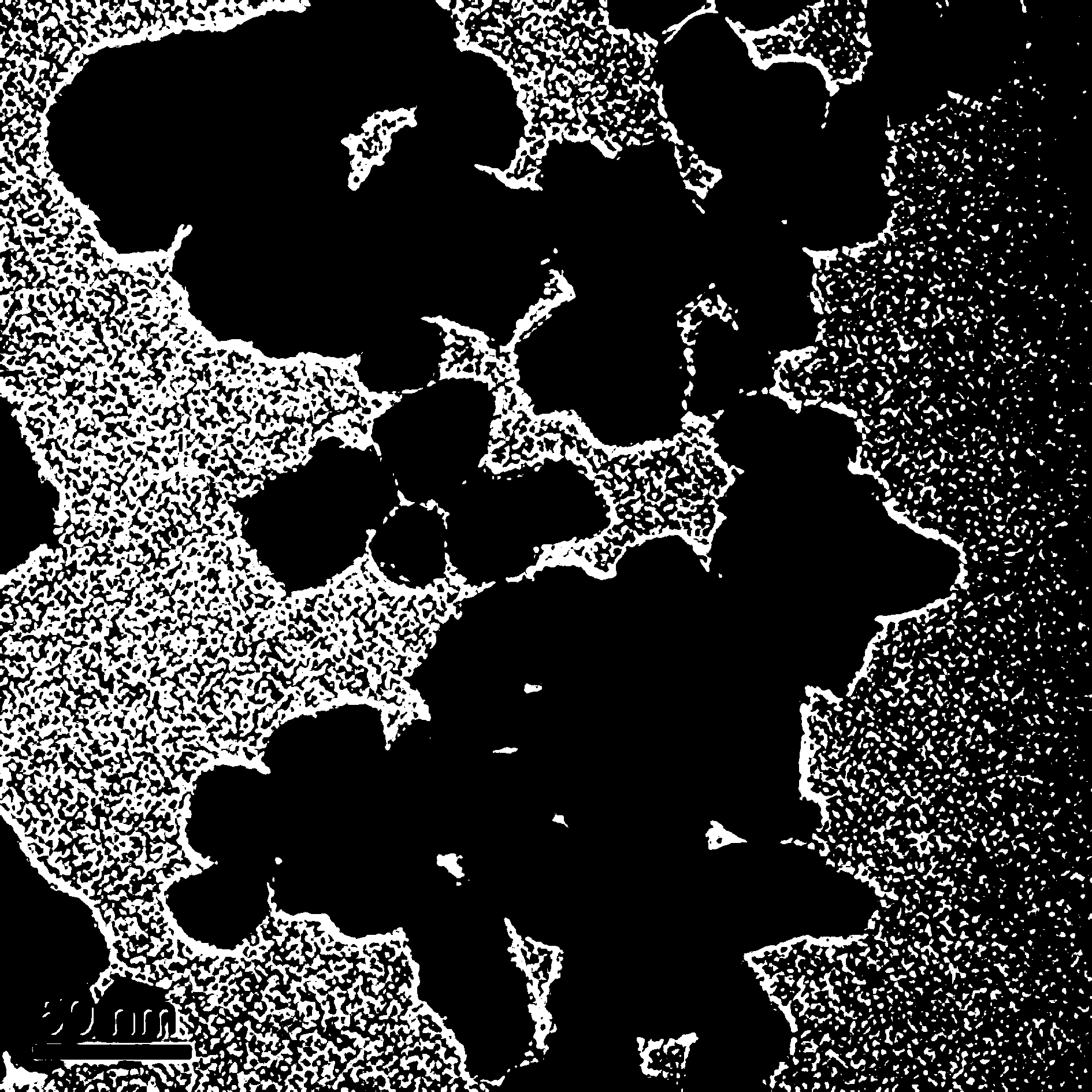

Image

Examples

Embodiment 1

[0033] (1) with ZrOCl 2 ·8H 2 O, Y 2 o 3 Add the third component as the raw material at the same time to form a mixed aqueous solution, and the Zr in the mixed solution 4+ The concentration is 0.8mol / L, and the oxide contents of each component combined are: zirconia 80wt%, yttrium oxide 8wt%, alumina 6wt%, magnesium oxide 3wt%, calcium oxide 3wt%;

[0034] (2) Add a precipitant to the mixed solution under stirring to form a hydroxide precipitate, and the added precipitant is an organic base ethylenediamine.

[0035] (3) The obtained hydroxide is subjected to microwave hydrothermal decomposition reaction to generate oxides. The microwave hydrothermal decomposition reaction generates oxides in a special reaction kettle, and the microwave hydrothermal temperature is 180°C.

[0036] (4) Ball mill and stir the nano-oxide generated by hydrothermal treatment, and the milling time is 5 hours;

[0037] (5) Wash the nanopowder after ball milling;

[0038] (6) Add appropriate amoun...

Embodiment 2

[0046] (1) with ZrOCl 2 ·8H 2 O, Y 2 o 3 Add the third component as the raw material at the same time to form a mixed aqueous solution, and the Zr in the mixed solution 4+ The concentration is 2mol / L, combined with its oxide content are: zirconia 95wt%, yttrium oxide 2wt%, magnesium oxide 1wt%, iron oxide 0.5wt%, cerium oxide 1.5wt%.

[0047] (2) Add a precipitant to the mixed solution under stirring to form a hydroxide precipitate, and the added precipitant is inorganic alkali sodium hydroxide.

[0048] (3) The obtained hydroxide is subjected to microwave hydrothermal decomposition reaction to generate oxides. The microwave hydrothermal decomposition reaction generates oxides in a special reaction kettle, and the microwave hydrothermal temperature is 200°C.

[0049] (4) Ball mill and stir the nano-oxide generated by hydrothermal treatment, and the milling time is 6 hours;

[0050] (5) Wash the nanopowder after ball milling;

[0051] (6) Add appropriate amount of distill...

Embodiment 3

[0059] In Example 2, the third component containing titanium oxide was added so that the content of titanium oxide was 0.2wt%, and the content of cerium oxide was 1.3wt%, and the test was carried out without changing the others.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com