Reaction type hot melting sealing agent composition for solar cell

A technology of solar cells and hot-melt sealant, which is applied in the direction of circuits, adhesives, photovoltaic power generation, etc., can solve problems such as damaged appearance, reduced strength, and battery function damage, and achieves suppression of extrusion, good heat resistance, and heat resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

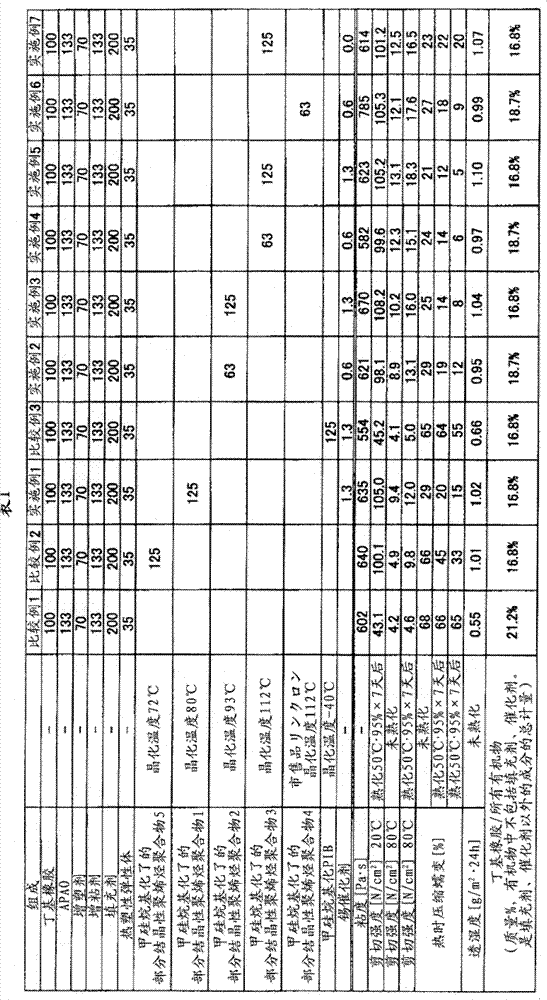

[0097] Examples are listed below to specifically illustrate the present invention. However, the present invention is not limited by the Examples.

[0098]

[0099] Each component shown in Table 1 below was blended in the composition (parts by mass) shown in Table 1 with respect to 100 parts by mass of butyl rubber, and uniformly dispersed using a universal mixer to obtain a sealant composition.

[0100] Viscosity, shear strength, compression creep during heat, and moisture permeability were measured for each of the obtained sealant compositions in the following manner. The results are shown in Table 1 below.

[0101]

[0102] The viscosity at 190° C. of the sealant composition obtained as described above was measured on the condition of 1 rpm using a rotational viscometer.

[0103]

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com