Water-based polysiloxane ceramic simulating coating

A technology of polysiloxane and imitation porcelain coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the limitations of high efficiency, large-scale application development of water-based polysiloxane imitation porcelain coatings, low viscosity of coatings, and short storage time and other problems, to achieve the effect of improving the scope of use and operating efficiency, short curing time and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

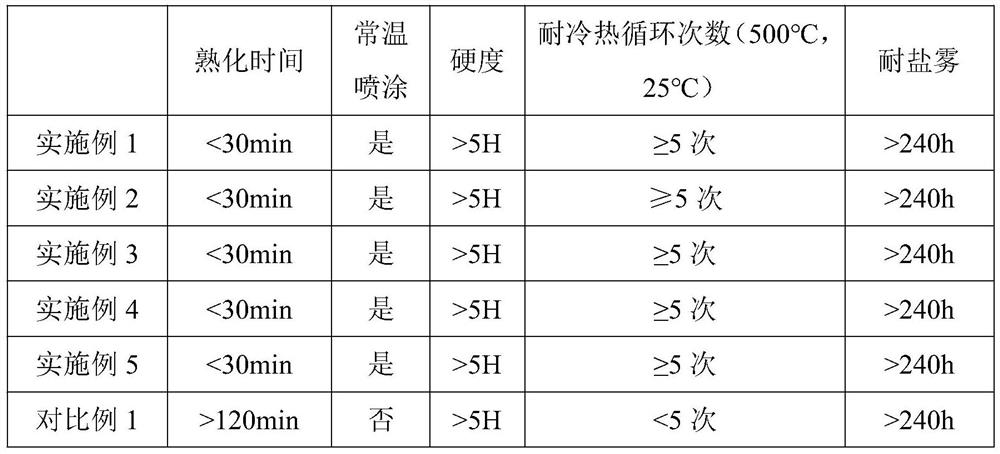

Examples

preparation example Construction

[0021] The preparation method of water-based polysiloxane imitation porcelain coating of the present invention is as follows:

[0022] (1) Mix and stir the substances in the A component evenly, grind and filter to obtain a colloid with a particle size of less than 20 microns, and set aside.

[0023] (2) Mix and grind the colloid, component B and component C of component A, mix according to the mass ratio of 10: (1~10): (0.1~5), stir evenly, and ultrasonic for 5 minutes, The finished product of water-based polysiloxane imitation porcelain paint can be obtained.

Embodiment 1

[0025] A water-based polysiloxane enamel paint is composed of A component, B component and C component, and the contents of each component are as follows:

[0026] Component A: 60g silica hydrosol (solid content: 30%), 20g talcum powder, 15g copper chrome black, 2g carbon black, 1g hydrophilic nano-silica, 1g nano-potassium aluminum silicate, 0.5 BYK110 dispersant g, BYK333 leveling agent 0.5g.

[0027] B component: Glacial acetic acid 10g.

[0028] Component C: 20 g of methyltrimethoxysilane.

[0029] After mixing and stirring all the materials in the above-mentioned component A, grind and filter to obtain a colloid with a particle size of 10-20 microns, which is set aside. Then mix and grind the colloid of component A, component B and component C according to the mass ratio of 10:1:2, and ultrasonicate for 5 minutes to obtain the finished water-based polysiloxane imitation porcelain coating.

Embodiment 2

[0031] A water-based polysiloxane enamel paint is composed of A component, B component and C component, and the contents of each component are as follows:

[0032] Component A: 70g titanium oxide hydrosol (solid content: 30%), 10g calcium carbonate, 15g titanium dioxide, 2g cellulose, 2.8g bentonite, 0.1g BYK110 dispersant, 0.1g BYK333 leveling agent.

[0033] B component: hydrochloric acid aqueous solution 20g (concentration 1%).

[0034] Component C: 30g of dimethyldimethoxysilane, 20g of methyltriethoxysilane.

[0035] After mixing and stirring all the materials in the above-mentioned component A, grind and filter to obtain a colloid with a particle size of 10-20 microns, which is set aside. Then mix and grind the colloid, component B and component C according to the mass ratio of component A to 10:2:5, mix and stir evenly, and ultrasonicate for 5 minutes to prepare the water-based polysiloxane imitation porcelain coating finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com