Revolving bed device and method for quickly mixing and dissolving polymers

A mixed-dissolution and rotating bed technology, applied in the fields of polymer dispersion, curing production, and dissolution, can solve the problems of uneven axial distribution of liquids, reduced dissolution efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

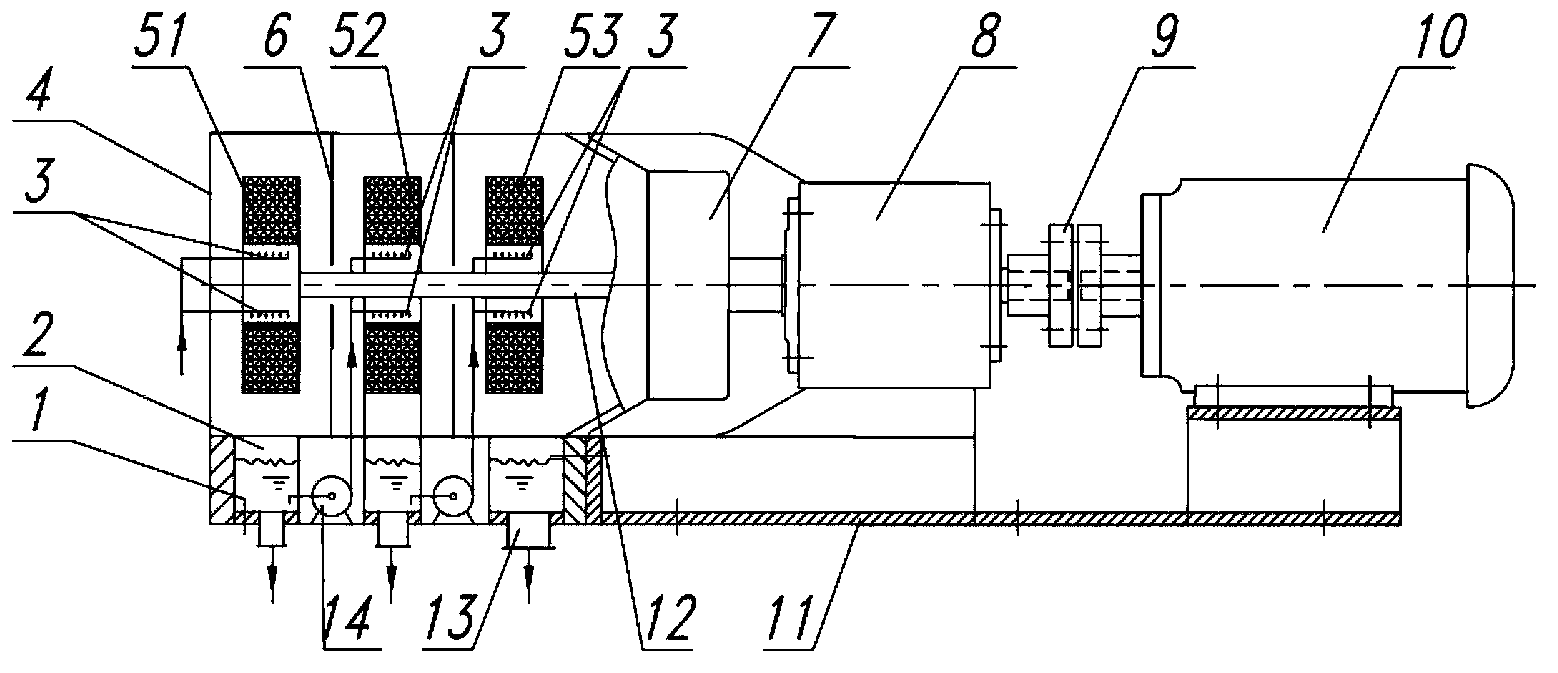

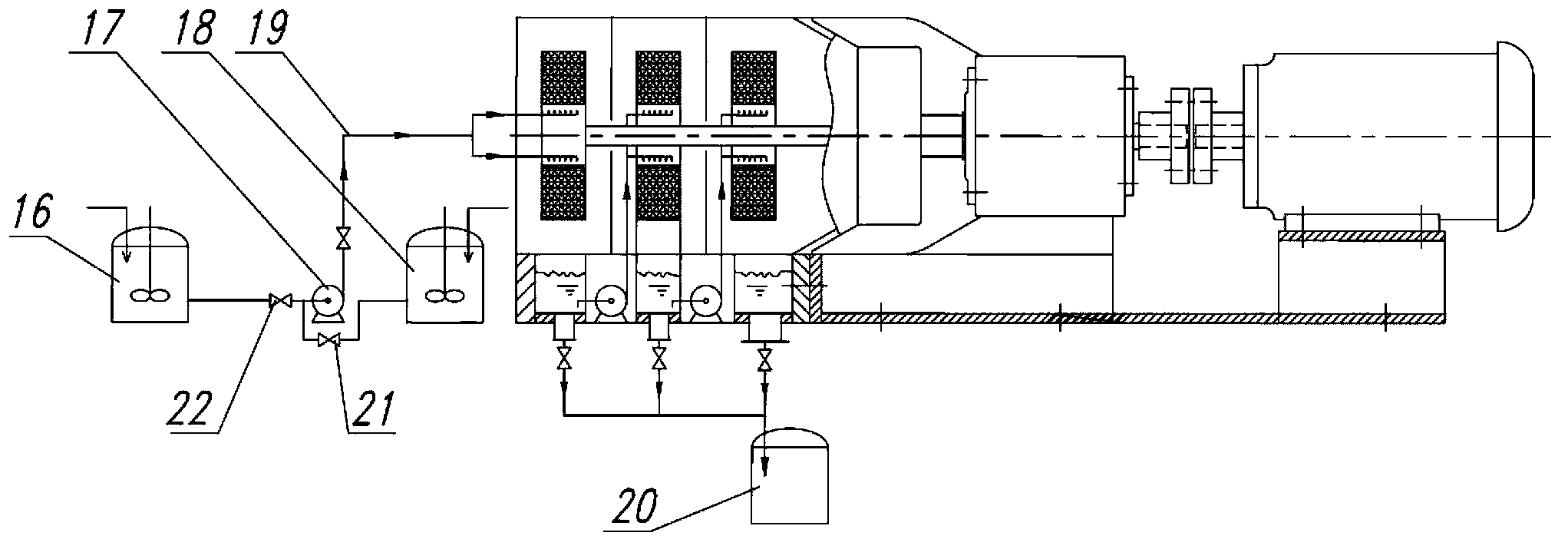

[0038] Weigh 8284.48g of pure water and pour it into the suspension stirring tank 16, turn on the stirring paddle, and slowly add 45.52g of polyacrylamide dry powder with a molecular weight of 25 million (water content 8.59%) into the suspension stirring tank 16. Under the action of the stirring paddle, the dry powder is preliminarily dispersed in water to form a polymer suspension with a premixed concentration of 5000mg / L. Maintain the system temperature at room temperature, turn on the supergravity rotating bed, and simultaneously turn on the liquid inlet valve 22 and the external liquid inlet pump 17. Under the action of the pump, the polymer suspension enters the inner cavity of the supergravity rotating bed rotor through the delivery pipe 19 at a flow rate of 100L / h through the liquid inlet spray pipe, and the polymer solution is cut into fine particles under the high-speed shear of the filler. The liquid droplets, liquid film, and liquid filaments make the solution gradu...

Embodiment 2

[0040] Open the stirring tank stirring paddle, weigh 13266.63g of pure water and 58.25g of polyacrylamide dry powder (moisture content 8.59%) with a molecular weight of 19 million and add them to the suspension stirring tank 16 and the suspension stirring tank 18 respectively. Both are 4000mg / L suspension. Maintain the system temperature at room temperature, turn on the supergravity rotating bed, and simultaneously turn on the liquid inlet valve 22 and the external liquid inlet pump 17. Under the action of the pump, the polymer suspension passes through the delivery pipeline 19 at a flow rate of 150L / h and sprays through the inlet liquid The pipe enters the inner cavity of the supergravity rotating bed rotor, and after the shearing action of the second-stage rotor, the cooking liquid flows out from the liquid outlet and enters the cooking liquid storage tank 20 . After the polymer suspension in the suspension stirring tank 16 has been exported, close the liquid inlet valve 22,...

Embodiment 3

[0042] Pure water and polyacrylamide dry powder with a molecular weight of 19 million (moisture content 8.59%) are used as raw materials for preparation. Turn on the stirring blade in the stirring tank, and continuously add the two raw materials into the suspension stirring tank 16 according to the mass ratio of pure water to dry powder of 151.35:1, and form a polymer suspension with a polymer concentration of 6000 mg / L. Maintain the system temperature at room temperature, turn on the supergravity rotating bed, and simultaneously turn on the liquid inlet valve 22 and the external liquid inlet pump 17. The polymer suspension enters the inner cavity of the supergravity rotating bed rotor through the delivery pipe 19 at a flow rate of 80 L / h through the liquid inlet spray pipe. After the liquid is thrown out from the outer edge of the first-stage rotor, it is collected by the liquid storage tank, and the ripening liquid flows out from the liquid outlet and enters the ripening liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com