Basement layer stiffened side mold construction method

A construction method and side form technology, applied in the direction of roads, road repairs, roads, etc., can solve the problems of difficulty in ensuring the degree of compaction of water-stabilized edges, sections that cannot reach the designed width, and additional engineering quantities, so as to save materials, The operation is simple and practical, and the effect of saving engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

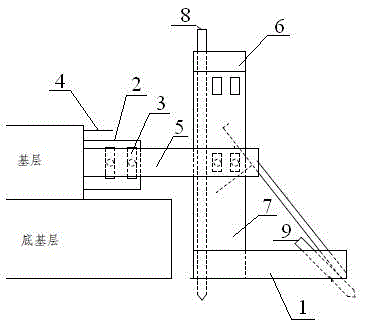

[0035] Such as figure 1 Shown, a kind of grass-roots stiffening side form construction method comprises the following steps:

[0036] ⑴ Accurately measure the paving width position before construction, so that there is no deviation.

[0037] ⑵Making L-shaped steel corbels:

[0038] The equilateral angle steel III6 is connected to the steel plate II7 by single-sided lap welding, and the steel plate II7 is connected to the equilateral angle steel I1 by single-sided lap welding with a weld length not less than 5cm through the steel bar II to form an L-shaped steel plate corbel.

[0039] Among them: the specification of equilateral angle steel III6 is 45mm×45mm×3mm. The thickness of the steel plate II7 is 10 mm. The specification of steel bar II is Ф16mm. The specification of equilateral angle steel I1 is 63mm×63mm×4mm.

[0040] (3) Pass one end of the steel braze I8 through the equilateral angle steel III6 and bury it parallel to the steel plate II7 at 25cm below the subgrad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com