Antipollution filter box-body with quick clamp shaft

A clamping shaft and anti-pollution technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of increasing the time for workers to receive radiation, large leakage of filter boxes, and ineffective air. Filtration and other issues to achieve the effect of reducing the replacement time and the time for staff to receive irradiation, and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

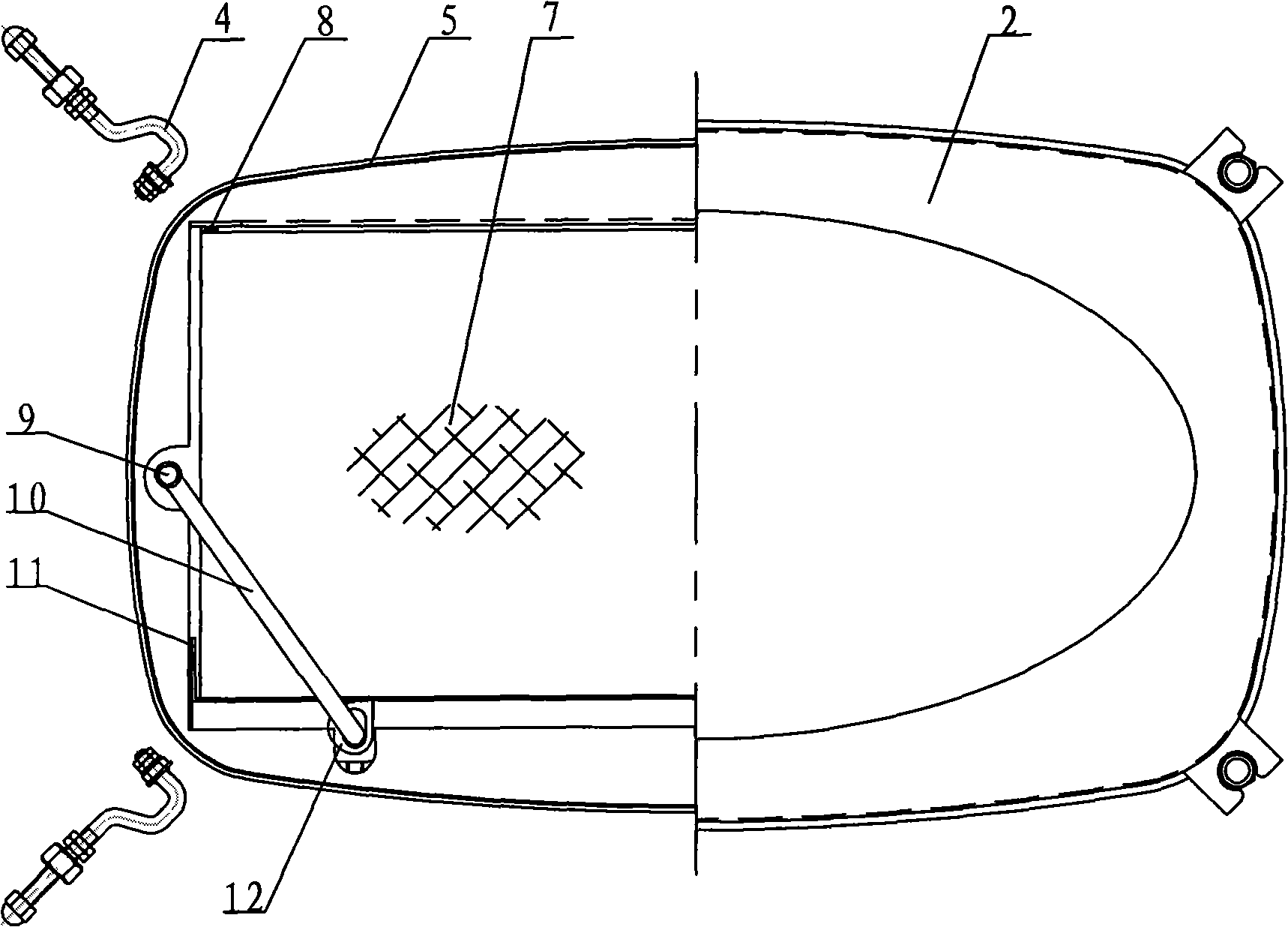

[0009] see Figure 1-Figure 3 As shown, this embodiment includes a box shell 1, a box cover 2, a socket wrench 3, a locking member 4, a sleeve 5, a cover sealing ring 6, a filter element 7, a foamed PVC gasket 8, and an operating handle 9 , Quick clamping shaft 10, filter element bracket 11, cam 12.

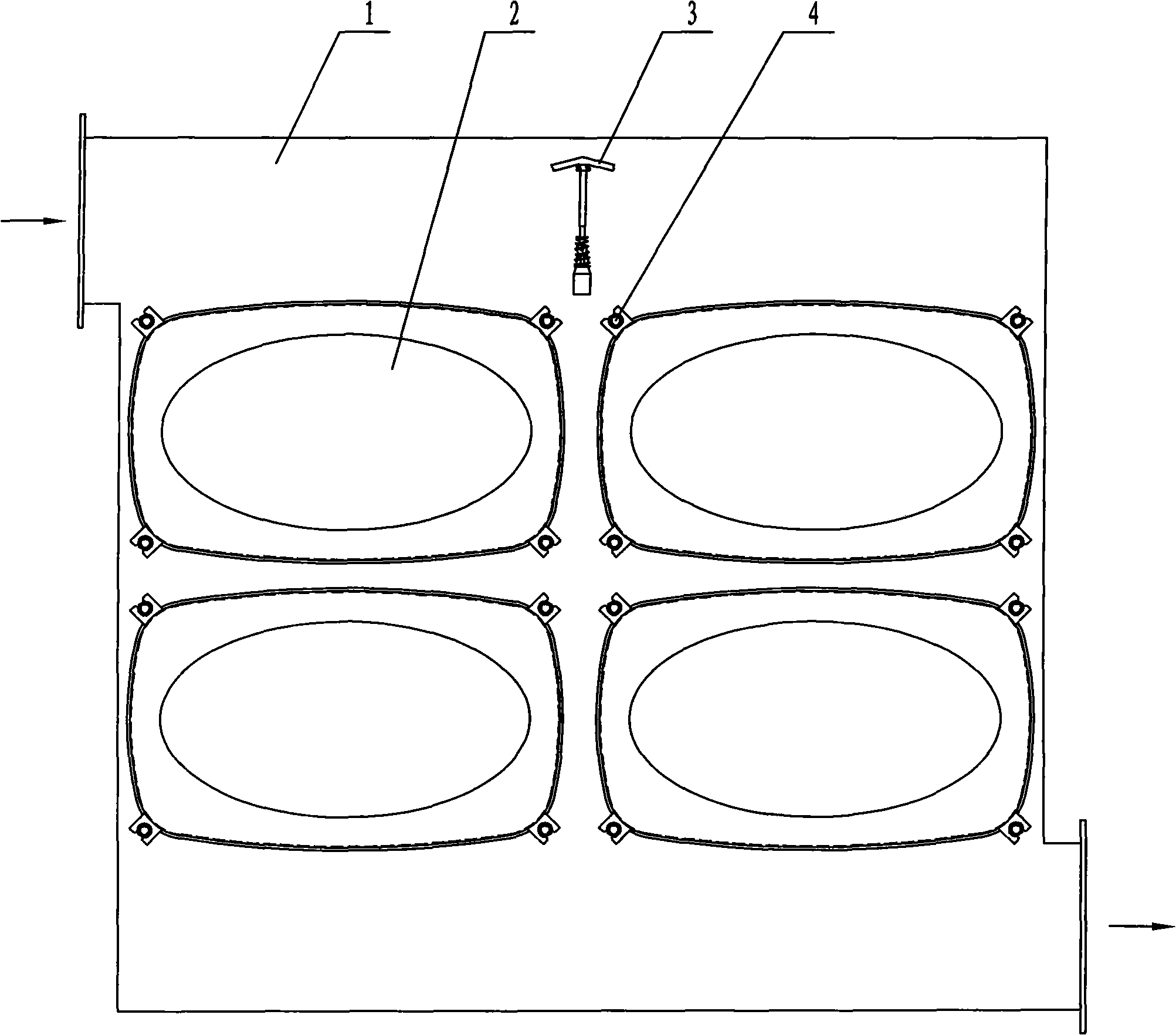

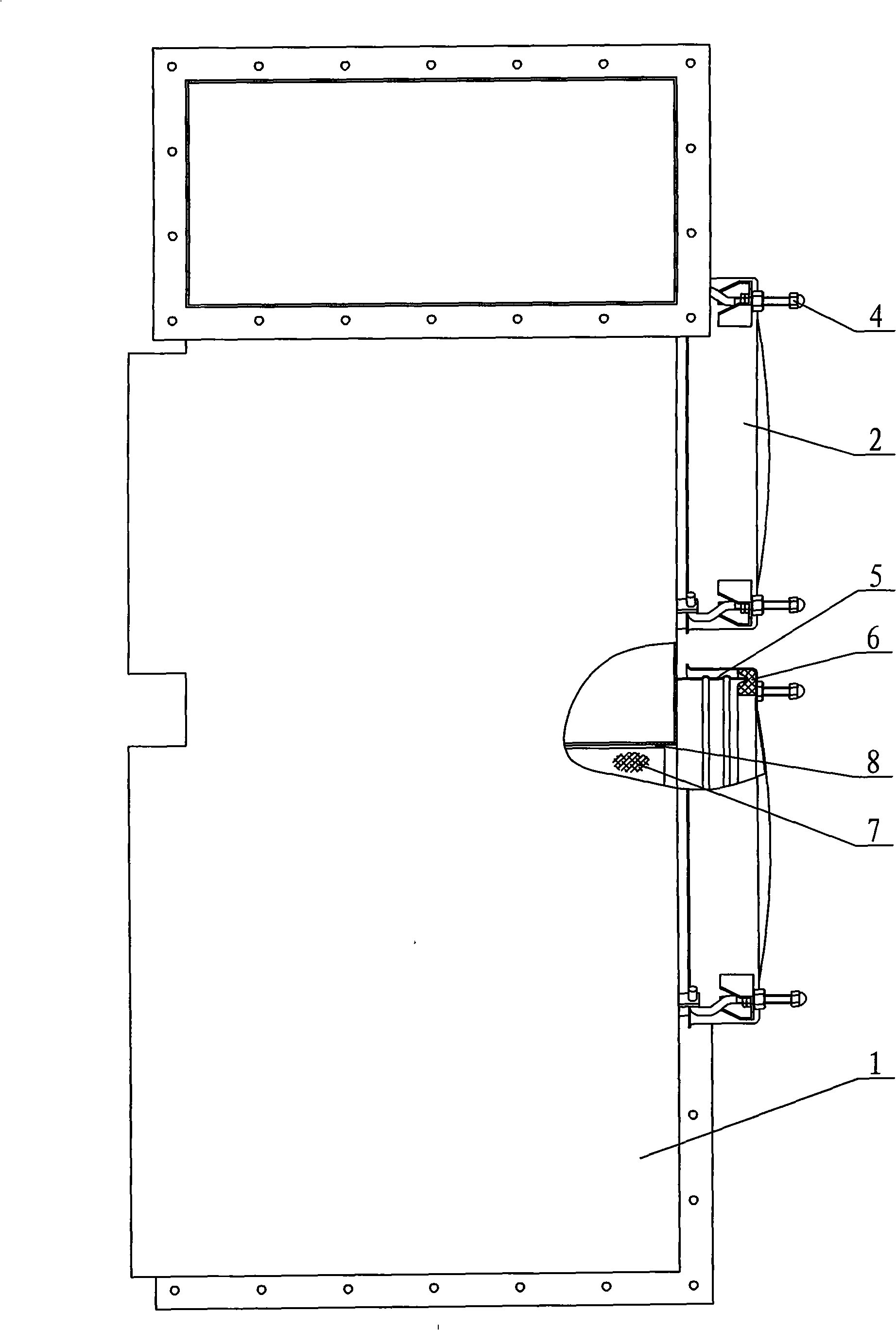

[0010] see figure 1 As shown, in this embodiment, except for the sealing material, the other main components are made of stainless steel. One or more filter element units are installed in each box, and the filter element units are installed on the operating surface of the box body, and the installation port of each filter element unit is sealed with the box body cover. Each box cover 2 is fixed on the box shell 1 with four locking pieces 4 , and the socket wrench 3 is hung on the box shell 1 .

[0011] see figure 2 , image 3 As shown, each sleeve corresponds to a filter element unit, and is welded to the filter element installation port on the operating surface of the box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com