Automatic square tin can branding device

A technology for labeling cans and labels, which is applied to labeling, labeling machines, labels, etc., and can solve problems such as complex labor costs and increased white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

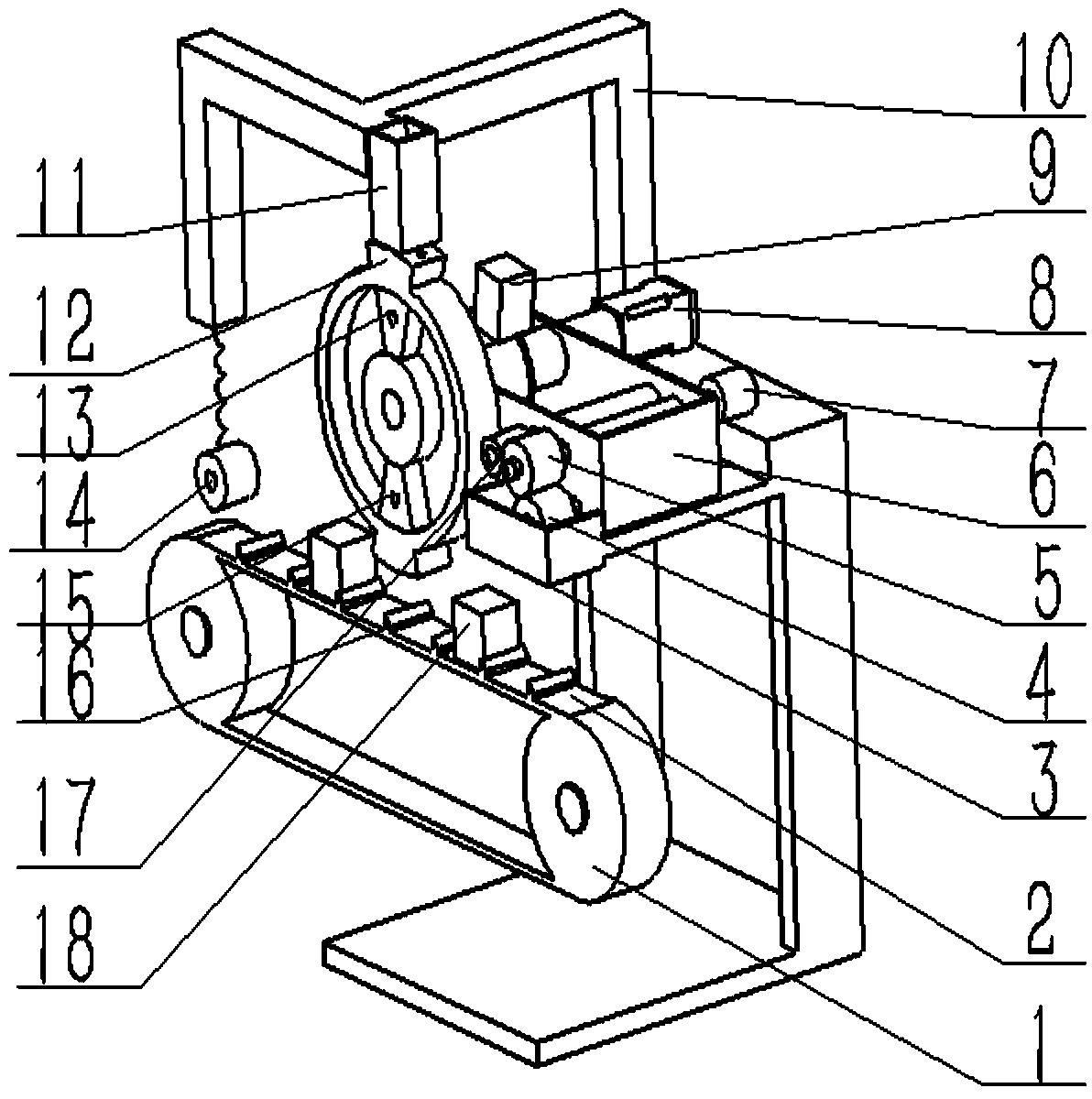

[0008] Such as figure 1 As shown, an automatic labeling device for square cans, including a pulley 1, a conveyor belt 2, a glue box 3, a first upper rubber roller 4, a second upper rubber roller 5, a bearing seat 6, a motor 7, and a stepping motor 8 , air pump 9, frame 10, trademark box 11, main wheel 12, suction port 13, pressure brush 14, blowing port 15, conveyor belt positioning block 16, the third upper rubber roller 17, can box 18, installed on frame 10 The stepper motor 8 on the rear boss is connected to the main wheel 12 through a coupling and shaft, the air pump 9 is fixed on the shaft between the stepper motor 8 and the main wheel 12, and the motor installed on the rear boss of the frame 10 7 is connected with the second upper rubber roller 5 through the shaft, the glue box 11 is welded in front of the frame 10, the trademark box 11 welded on the top of the frame 10 is located at 3-5 mm directly above the main wheel 12, the suction port 13, the blower The air port 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com