Cement stabilized macadam base construction method

A technology of cement-stabilized gravel and construction method, applied in the directions of roads, road repair, roads, etc., can solve the problems of inability to guarantee the compaction on both sides of the road base, waste of people, materials, machines, and lower edge elevation, etc. To achieve the effect of internal compaction, reducing voids and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

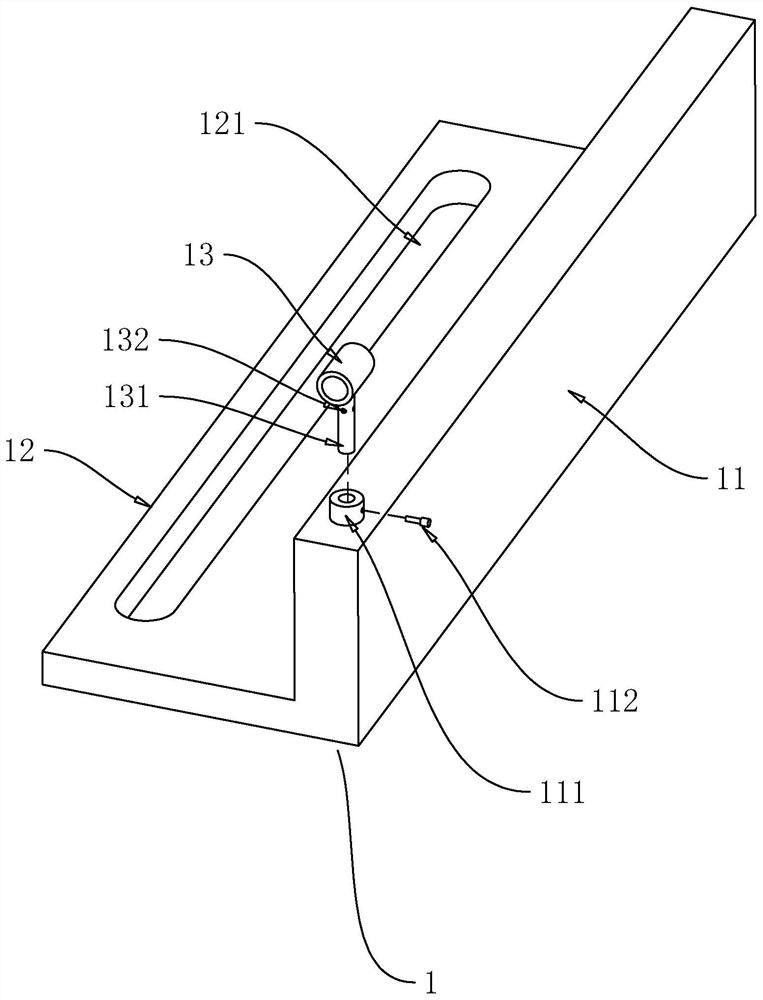

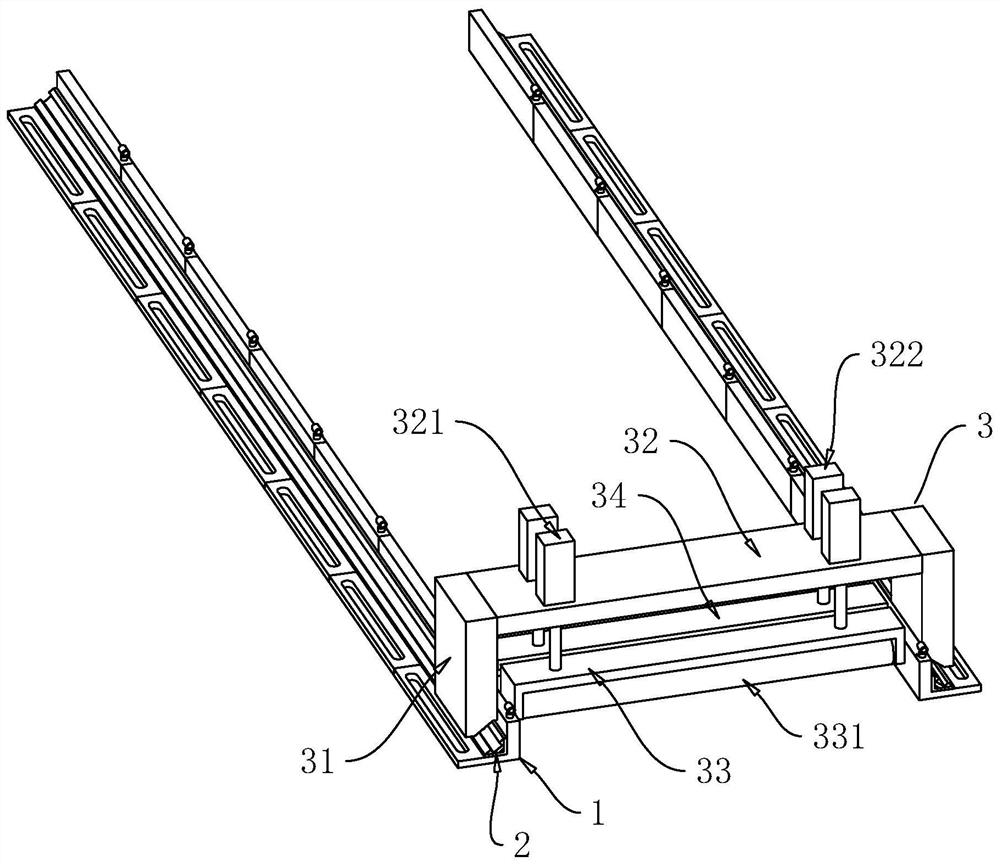

[0044] The following is attached Figure 1-5 The application is described in further detail.

[0045] The embodiment of the application discloses a cement-stabilized gravel base construction method.

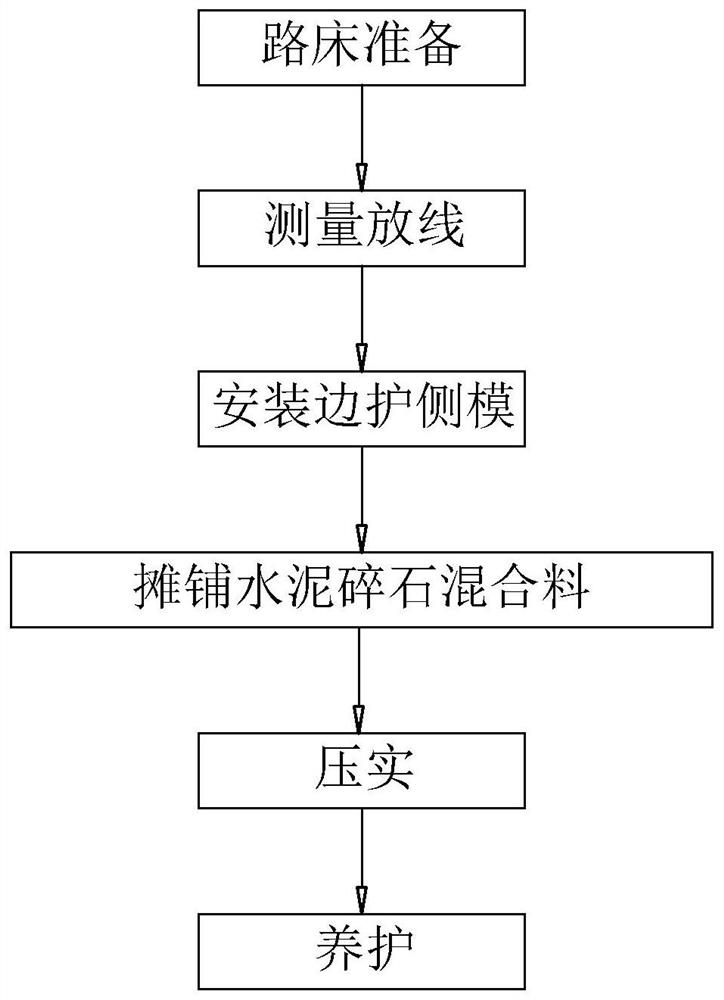

[0046] refer to figure 1 , a cement stabilized crushed stone base construction method, comprising the following steps

[0047] S1: Road bed preparation:

[0048] 1. Repair the road bed: repair the road bed to ensure that the surface of the road bed is flat and solid, and the elevation, centerline deviation, width, transverse slope and flatness of the road bed should comply with the provisions of the "Technical Specifications for Highway Subgrade Construction" (JTGF10-2006) ;

[0049] 2. Remove all floating soil and sundries on the road bed, keep the surface clean, and properly sprinkle water to moisten it;

[0050] 3. The ruts, soft and non-compliant parts on the road bed shall be excavated and removed, and repaired with similar materials. The compacted thickness shall not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com