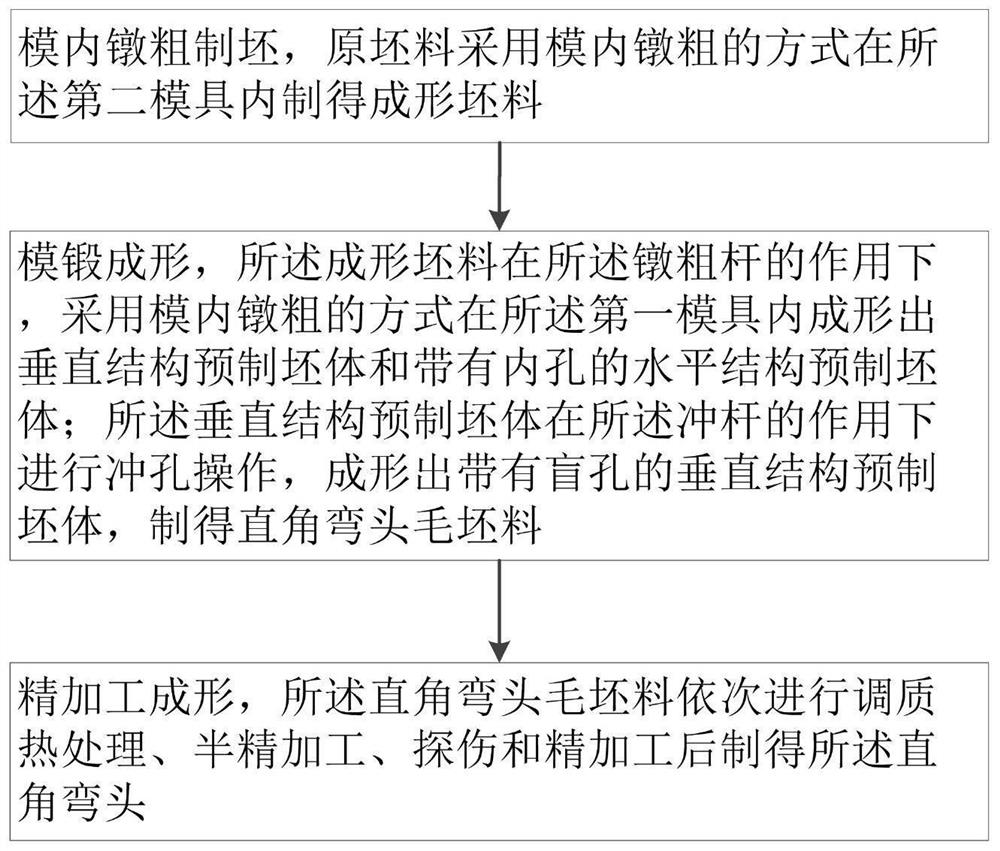

Die-forging forming die and method for ultra-large square elbow

A right-angle elbow and forming die technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problem of increasing pollutant emissions, affecting product performance and quality, and large energy consumption and other problems, to achieve the effect of small machining amount, saving free forging, upsetting, drawing and compaction process, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

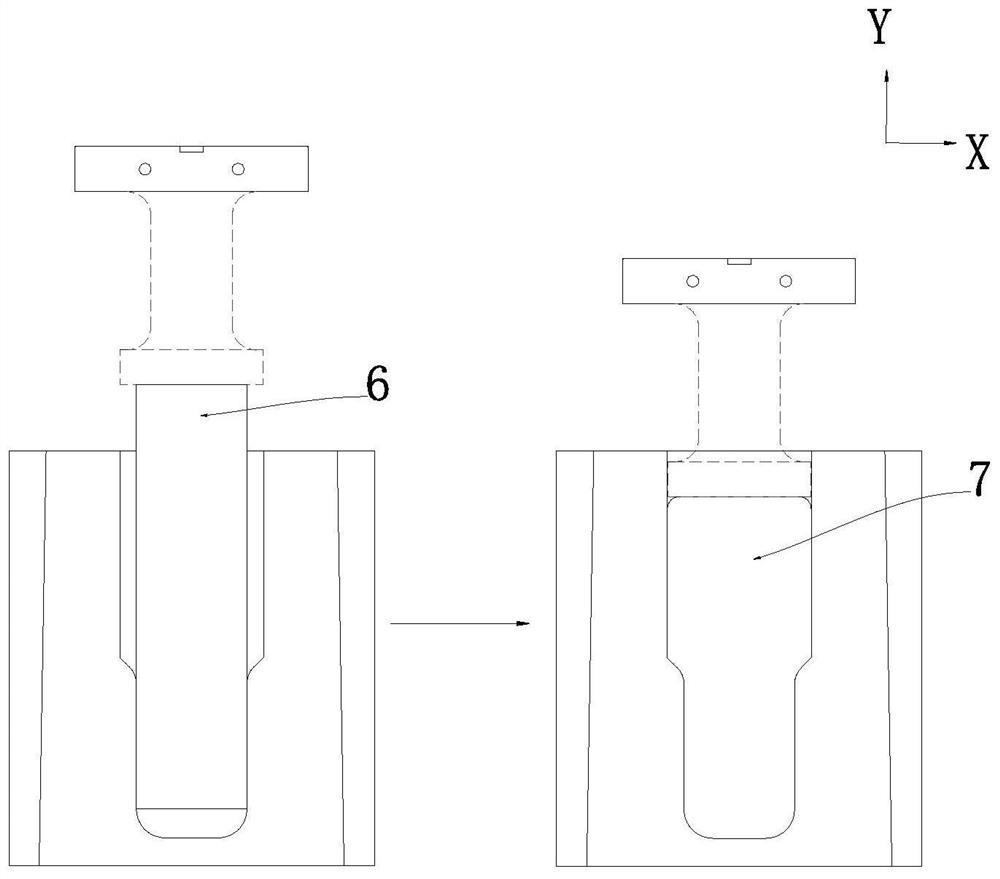

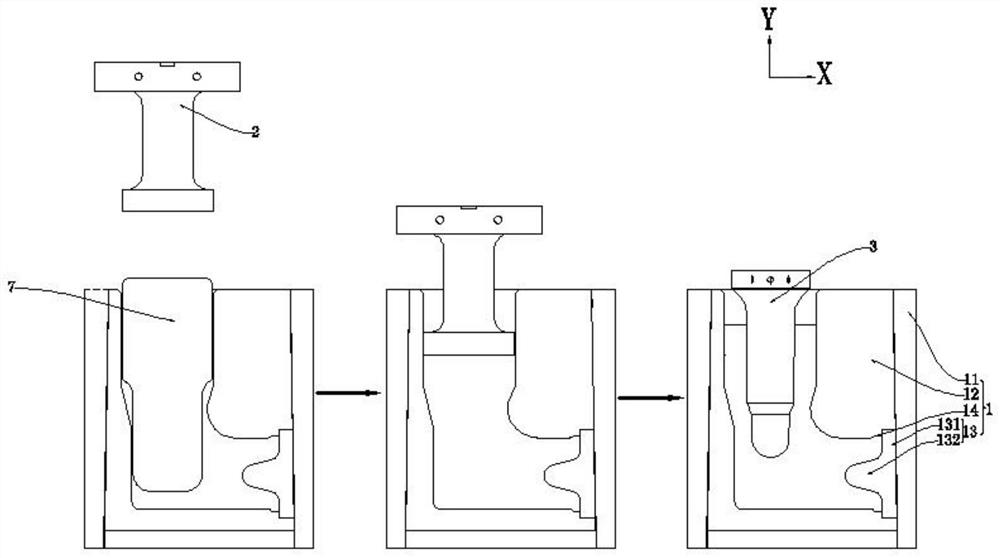

Method used

Image

Examples

Embodiment Construction

[0037] The manufacturing method of the main pump connection in the prior art generally includes: smelting→ingot casting→free forging forming→rough machining→quenching and tempering heat treatment→semi-finishing→flaw detection→finishing. Steel ingots, hot sent to the forging plant, press the jaws, cut off the waste at the bottom of the ingot, because the thickness of the forgings is thick, in order to ensure the forging ratio of the core, to make the internal shrinkage defects of the forgings forged, two times of upsetting and drawing are required, and The ratio of single upsetting and drawing must be greater than 2. After two times of upsetting and drawing, the front end of the forging is blanked flat, square and rounded to make the main pump takeover blank.

[0038] However, in the above-mentioned manufacturing methods, on the one hand, the smelting and pouring time of die-casting steel ingots is long, the forging fires are many times, and the forging heat preservation time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com