Manufacturing process of environment-friendly packaging tin

A production process and technology of packaging cans, which is applied in the field of production process of packaging cans, can solve the problems of high cost, poor sealing performance, complicated process, etc., and achieve the effects of good sealing performance, pollution prevention and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

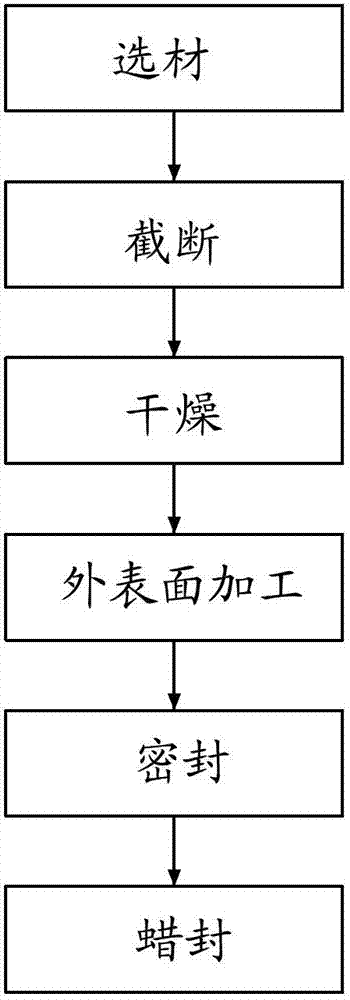

[0022] Such as figure 1 Shown is a flow diagram of a preferred embodiment of the present invention, the manufacturing process of the environmental protection packaging jar of this embodiment, comprises the following steps:

[0023] Material selection steps, select bamboo materials more than three years old.

[0024] The step of truncating, cutting off the bamboo material and leaving a bamboo node to form a bamboo tube with an open end and a closed end;

[0025] Drying step: Dry the cut bamboo at a temperature not higher than 80°C until the moisture content is below 4%. If the temperature is too high, the bamboo will easily explode; The drying can be completed in -4 days; of course, in other embodiments, natural drying can also be adopted, and the required time is longer.

[0026] External surface processing step: processing the shape and pattern of the external surface of the bamboo tube to increase the aesthetics and identification of the packaging can.

[0027] Sealing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com