Rotary type tin can subpackaging counting mechanism

A counting mechanism, rotary technology, applied in the field of rotary tin can packaging counting mechanism, can solve the problems of time-consuming, laborious, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

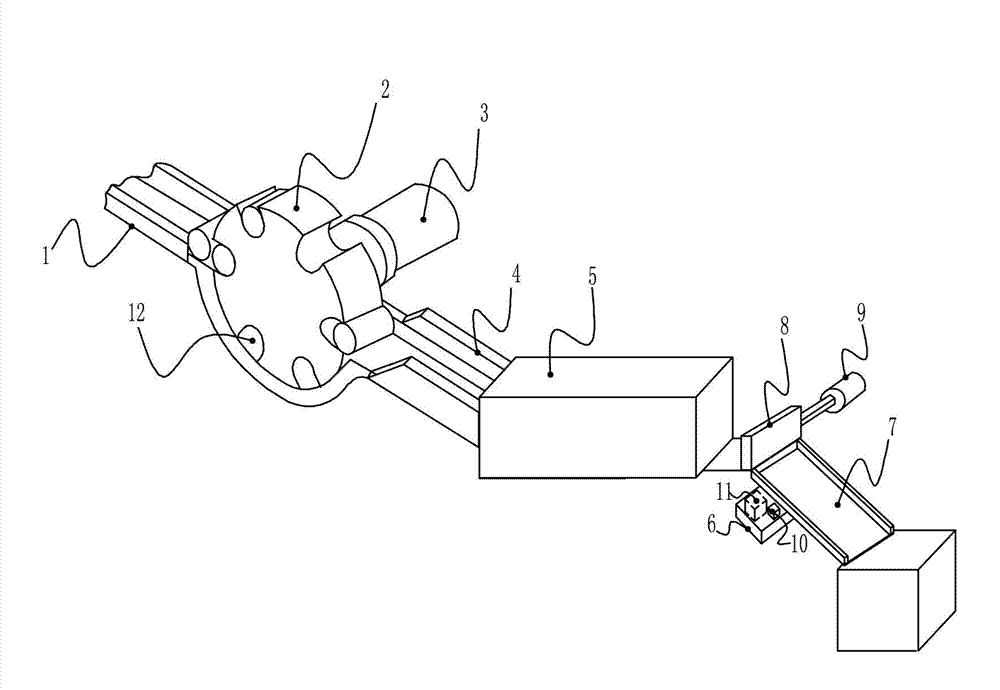

[0011] like figure 1 Shown: Rotary tin can filling and counting mechanism, including a separation part and a packaging part, the separation part includes a feed chute 1 and an index plate 2 radially embedded in the feed chute 1, the index plate 2 Separation grooves 12 are evenly distributed on the upper circumference, the index plate 2 is connected to the rotary cylinder 3, and the side wall of the feed chute 1 close to the index plate 2 is provided with a side baffle 4 to prevent tin cans from flying out; the packaging department includes a cooling warehouse 5. The counter 6 and the loading chute 7, the cooling bin 5 accommodates the feeding chute 2, the loading chute 7 is installed at the end of the feeding chute 2, the counter 6 is installed on the loading chute 7, and the loading chute 7 The beginning end is provided with a baffle 8, the baffle 8 is connected with a rotary cylinder 9, a fan is evenly provided on the inner top surface of the cooling chamber 5, and an iron n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com