Recovery method of lead in waste circuit board

A waste circuit board, recycling method technology, applied in the field of waste circuit boards, can solve the problems of waste electrolyte pollution, lead pollution, large consumption of chemical agents, etc., achieve simple and easy recycling method, reduce environmental pollution, avoid secondary The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

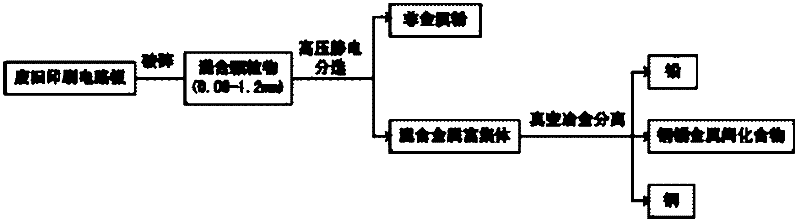

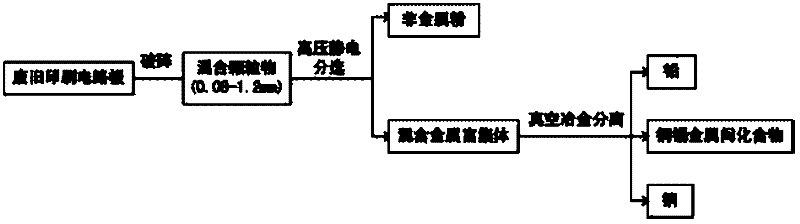

Method used

Image

Examples

Embodiment 1

[0024] First, waste circuit boards are crushed into mixed materials with a particle size of 0.08-1.0mm, and then, through high-voltage electrostatic separation, the corona electrode voltage range is 10kv, and 174g of lead-containing mixed metal-enriched body raw materials are obtained, copper accounts for 93wt%, and lead 4wt% tin, 2wt% tin, put into a crucible, and then put the crucible into a vacuum furnace. After the vacuum furnace is sealed, start the vacuum system to pump air, so that the vacuum degree of the vacuum furnace is 0.01Pa. Start the heating body in the vacuum furnace to heat the crucible, and heat the mixed metal particles in the crucible to 800°C. Then keep the temperature constant to evaporate the lead in the raw material, and the evaporation time is 2 hours. The lead vapor is condensed on the condenser, the condensation temperature is 365°C, 6.3g of lead is recovered, the lead recovery rate is 91.0%, the purity is 99.1%, and 16.6g of copper-tin intermetalli...

Embodiment 2

[0026] First, waste circuit boards are crushed into mixed materials with a particle size of 0.1-1.0mm, and then, through high-voltage electrostatic separation, the corona electrode voltage is 50kv, and 42g of lead-containing mixed metal-enriched body raw materials are obtained, copper accounts for 93wt%, and lead accounts for 2wt%, tin accounted for 3wt%, put into the crucible, and then put the crucible into the vacuum furnace. After the vacuum furnace is sealed, start the vacuum system to pump air, so that the vacuum degree of the vacuum furnace is 100Pa. Start the melting heating body in the vacuum furnace to heat the crucible, and heat the mixed metal in the crucible to 1000°C. Then keep the temperature constant to evaporate the lead in the raw material, and the evaporation time is 1 hour. The lead vapor was condensed on the condenser, the condensation temperature was 200°C, the lead recovery rate was 93.0%, the purity was 99.5%, and 5.6g of copper-tin intermetallic compou...

Embodiment 3

[0028] First, waste circuit boards are crushed into mixed materials with a particle size of 0.1-1.2mm, and then, through high-voltage electrostatic separation, the corona electrode voltage is at 20kv, and 10g of lead-containing mixed metal-enriched body raw materials are obtained, copper accounts for 95wt%, and lead accounts for 2wt%, tin accounted for 3wt%, put into the crucible, and then put the crucible into the vacuum furnace. After the vacuum furnace is sealed, start the vacuum system to pump air, so that the vacuum degree of the vacuum furnace is 10Pa. Start the smelting heating body in the vacuum furnace to heat the crucible, and heat the mixed metal in the crucible to 850°C. Then keep the temperature constant, the lead in the raw material is evaporated, and the evaporation time is 1.5 hours. The lead vapor is condensed on the condenser, the condensation temperature is 270°C, the lead recovery rate is 90.2%, the purity is 99.2%, and 1.1 g of copper-tin intermetallic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com