Method for preparing canned diced tomatoes

A technology for diced and canned tomatoes, which is used in food preparation, peeling of vegetables or fruits, food preservation, etc., can solve problems such as affecting product quality, color and nutrients, loss of rich nutrients in tomatoes, and easy loss of fresh tomato ingredients. , to achieve the effect of enhancing product competitiveness, individual tomato integrity, and increasing market share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

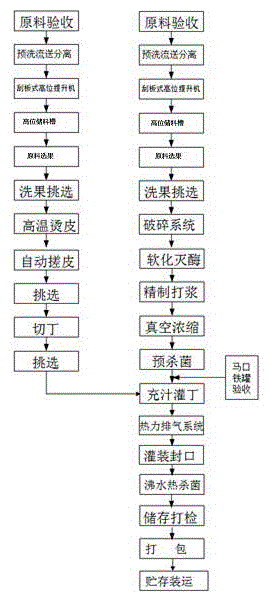

[0035] see figure 1 , in the embodiment of the present invention, a kind of preparation method of diced tomato, concrete steps are as follows:

[0036] (1) Acceptance of raw materials: when the annual production season comes, first conduct a general survey of the residues of pesticide residues, heavy metals and other harmful chemical substances in the raw material area where the factory is located or in the vicinity of the raw material, so as to determine the safe raw material area The supplier is included in the qualified supplier file, the raw material staff will issue sales cards for safe raw materials according to the plan, and the raw material quality inspector will conduct quality inspection and purchase of raw materials according to the tomato raw material procurement standards, and only those that meet the requirements can enter the factory; the qualified raw materials are poured into the factory. In the storage tank of the raw material pool, it is washed with water an...

Embodiment 2

[0058] see figure 1 , in the embodiment of the present invention, a kind of preparation method of diced tomato, concrete steps are as follows:

[0059] (1) Acceptance of raw materials: when the annual production season comes, first conduct a general survey of the residues of pesticide residues, heavy metals and other harmful chemical substances in the raw material area where the factory is located or in the vicinity of the raw material, so as to determine the safe raw material area The supplier is included in the qualified supplier file, the raw material staff will issue sales cards for safe raw materials according to the plan, and the raw material quality inspector will conduct quality inspection and purchase of raw materials according to the tomato raw material procurement standards, and only those that meet the requirements can enter the factory; the qualified raw materials are poured into the factory. In the storage tank of the raw material pool, it is washed with water an...

Embodiment 3

[0081] see figure 1 , in the embodiment of the present invention, a kind of preparation method of diced tomato, concrete steps are as follows:

[0082] (1) Acceptance of raw materials: when the annual production season comes, first conduct a general survey of the residues of pesticide residues, heavy metals and other harmful chemical substances in the raw material area where the factory is located or in the vicinity of the raw material, so as to determine the safe raw material area The supplier is included in the qualified supplier file, the raw material staff will issue sales cards for safe raw materials according to the plan, and the raw material quality inspector will conduct quality inspection and purchase of raw materials according to the tomato raw material procurement standards, and only those that meet the requirements can enter the factory; the qualified raw materials are poured into the factory. In the storage tank of the raw material pool, it is washed with water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com