Method for synthetically recycling waste printed circuit board

A printed circuit board and waste technology, which is applied in the field of waste printed circuit board recycling and processing, can solve the problems of high cost and low efficiency, and achieve the effects of low recycling cost, simple follow-up treatment and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

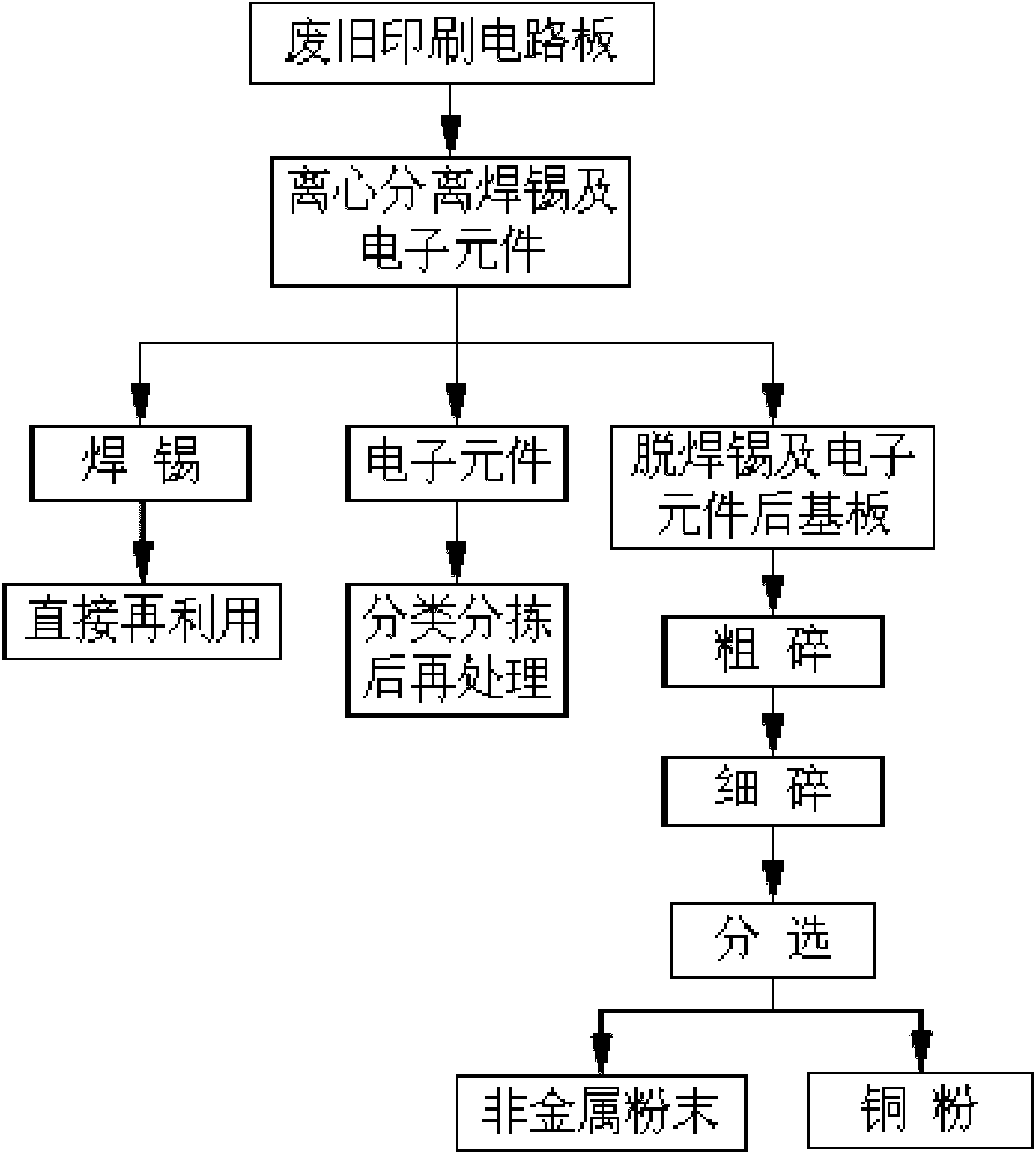

[0026] like figure 1 As shown, a method for comprehensively recycling waste printed circuit boards may further comprise the steps:

[0027] (a) Put the waste printed circuit boards with electronic components in the drum used for centrifugation, and then immerse in the liquid heating medium to melt the solder. Then, the motor is used to drive the drum to rotate at a high speed, and the molten solder is filtered out through the filter holes on the wall of the drum under centrifugal action, and separated from the waste printed circuit board. The liquid heating medium used can be one of diesel oil, kerosene, paraffin oil, silicone oil, etc., and the temperature of the heating medium is controlled at 220°C~300°C. The rotation speed is controlled at 800rpm~1000rpm, the rotation time is 5-20min, and the rotation mode is intermittent rotation. The shed solder will not be oxidized in the liquid heating medium, and is still collected in the form of solder, which can be directly reused...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com